3p Vertriebsgesellschaft

3p Vertriebsgesellschaft mbH specializes in the purchase and sale of used graphic industry machines, from prepress to post-press. Based near Berlin with excellent transport links, they offer a large stock, fast response, reliable logistics, and customer-focused service worldwide.

- Location Dabergotz | Germany

- Member Since 2025

Scan & Share

View :

-

11749

Luscher

XPose 230 UV

2012

CTP systems

Lüscher XPose 230 UV + PHS and TiFF Shooter including computer hardware for offset plates and water-based washable flexo printing plates 405 nm UV diodes for conventional offset printing plates and diazo films as well as coating plates from Mac Dermid (also rotary screens from Gallus, Kocher + Beck and Stork can be easily exposed with 405 nm UV) For the direct exposure of water-washable flexographic printing plates or conventional letterpress plates without LAMS layer, laser diodes with 375 nm are used 32 laser diodes with 375 nm for water-based washable flexographic printing plates 16 laser diodes with 405 nm Inline punch for Bacher 2000 Autoplate 780 mm and 425 m plate counter: 58,736 plates laser time: 4,030 hours sliprint revolutions: 30894729 Lüscher Plate Handling System PHS 230 with five plate magazines (can be omitted upon request) Transport table Glunz & Jensen IP 66 Offset printing plate processor AGFA Elantrix DX 85 with two brush rollers, built in 2017

Neuruppin Germany

Germany -

53483

Agfa

Avalon N8-60

2011

CTP systems

Agfa Avalon N8-6o with MAL and Apogee Rip, built in 2011 low counter reading 281956 with 5052 operating hours Speed: 33 plates per hour and Nela Punch The customer had a GOSS and a Heidelberg XL 106 the two Nela die-cutting machines are designed for offline manual cutting was used Avalon-N8_60-80

Neuruppin Germany

Germany -

6840

Heidelberg

Topsetter 102 SCL

2001

CTP systems

B1 Thermal CTP System 1 storage cassette Resolution 1200 – 4000 dpi min. 650 x 550 mm max. 1060 x 940 mm internal punch 780mm 32 diodes

Neuruppin Germany

Germany -

6868

Heidelberg

Suprasetter 74 S

2006

CTP systems

complete semi-automatic thermal CTP system Heidelberg with print-ready workflow and wash gumming Year of construction August 2006 Prinect Meta Shooter Prinect Meta Rip Prinect Meta Printraedy Workflow M Prinect Signastation PDF Toolbox Proof printer Epson internal plate punch 425mm Autoplate Suction for ablative plates internal autoplate punch 425mm max. plate format 680×750 mm min. plate format 370x323mm manual plate feed, automatic plate ejection Output capacity 19 plates / hour in full format Washing gum Glunz & Jensen C 85 with Stacker Advant PST 26

Neuruppin Germany

Germany -

6863

Heidelberg

Suprasetter 74 S

2004

CTP systems

with 4 laser heads, ie output 21 plates/hour Manual system with online bridge to development internal autoplate punch 425mm max. plate format 680×750 mm min. plate format 370x323mm Prinect Meta Shooter Prinect Meta Dimension Plate development Kodak Mercury 850

Neuruppin Germany

Germany -

12774

Heidelberg

Suprasetter 106 UV

2014

CTP systems

The device can be used to expose inexpensive conventional offset printing plates. approximately 86,000 exposed printing plates MetaShooter Auto Dual Cassette Loader Throughput: 23 plates/h at max. format Resolution: 2400 dpi, 2540 dpi Internal punch: Bacher Control 780 mm Glunz & Jensen printing plate processor Printing plate stacker PST 36

Neuruppin Germany

Germany -

6872

Heidelberg

Suprasetter 105

2005

CTP systems

Year of construction 2005 Thermal laser 830 nm for throughput of approximately 18 full-format plates per hour Single cassette loading system with two plate carriages Internal Heidelberg Autoplate register punch hole spacing 780mm Prinect MetaShooter Prinect MetaDimension Workflow Kodak Mercury 850 MK VI thermal development Kodak plate stacker with cart

Neuruppin Germany

Germany -

6862

Heidelberg

Suprasetter 105 S

2007

CTP systems

Year of construction 3- 2007 Laser power only approx. 3400 hours 3 thermal lasers 830 nm, for throughput of max. 21 plates/h Min. plate size (height × width) 370 × 323 mm Max. plate size (height × width) 930 × 1,140 mm Plate thickness 0.15-0.35 mm Resolution 2,400 or 2,540 dpi Internal punch pair 780 mm / 425 mm SCL Single Cassette Loader Fully automatic plate loading and unloading unit with automatic interleaf removal and integrated 90-degree bridge to the online processor Cassette with up to 100 plates (0.3 mm) or 150 plates (0.15 mm) Prinect MetaShooter Dimension Workflow 11.0 prepared for Heidelberg Lenticular exposure Kodak Mercury 850 plate developing machine Stacker with trolley

Neuruppin Germany

Germany -

6841

Heidelberg

Polysetter 52

2005

CTP systems

The polyester CTP system, which delivers color-separated, punched, and accurately registered polyester plates up to the maximum Heidelberg SM 52 format, which can be used immediately on the printing press. max. format: 460 x 550 mm Integrated register punch Online development Prinect MetaShooter

Neuruppin Germany

Germany -

18000

FUJI

PT-R 4300 S

2010

CTP systems

Fuji PT-R 4300 S with Fuji XMF software, no PC required! From 2010, 286,319 plates exposed so far under a Fuji full-service contract. Basket for paper single plate loader SA-L 4300II with 2 cassettes Imagesetter PT-R 4300S internal punch – Heidelberg Capacity: 20 plates B2/h Bridge Developer Glunz & Jensen Quartz III 85 Stacker Advant PST 360. Complete documentation

Neuruppin Germany

Germany -

6814

FUJI

PT-R 4300 E

2007

CTP systems

automatic thermal CtP system Fuji with Highwater Rip Version 8 OEM Screen PT-R 4300-E or Agfa Acento II E Commissioning 2007 only 9835 plate winding cycles, exposure time 1231 h SAL Single record loading cassette for 50 records without interleaved paper 16 thermal laser diodes 830nm Resolution 2400 dpi Output approx. 11 plates/h built-in punch HB 425mm (other punching patterns on request) min. format 324 x 370mm max. format 830 x 660mm Plate thickness 0.15-0.30mm Plate stacker

Neuruppin Germany

Germany -

6875

Esko

DPX4

2004

CTP systems

System: Internal drum CTP, fully automatic Speed: 27 plates/hour at 2,540 dpi Printing plates: Mitsubishi Silver Digiplate polyester plates Plate format: max. 680 x 750 mm Exposure format: max. 654 x 747 mm Integrated punch Bacher 2000, 425 mm Laser: Red light laser diode, 670 nm Spot size: 10 – 26 µm Resolution: 1,200 – 3,000 dpi Repeatability: 0.0075 mm print image to print image Development unit: integrated 2-bath development Dryer: integrated Material cassettes: 2 RIP software: RipMate, based on Harlequin Genesis Release Punching: Head and/or side punching

Neuruppin Germany

Germany -

Redefining Customer Acquisition in Machinery and Equipment Sales

Plans, Pricing & Subscriptions

-

6842

Esko

DotMate7500

1997

CTP systems

The DotMate 7500 is a highly productive B2+ imagesetter that can output conventional film material or polyester printing plates. Exposure format 610 mm x 750 mm 20 full-format films per hour Resolution of 900 – 3600 dpi internal Bacher punch Spot size (depending on resolution) 8 – 21 micron Repeatability +/- 5 microns Fully integrated online processor with desilvering of the fixer bath, controlled via console software on the RIP computer Inner drum technology with rip

Neuruppin Germany

Germany -

6830

Mitsubishi

DPX 460

2007

CTP systems

for the production of print-ready punched polyester printing plates for GTO, Ryobi 5x up to 3600 dpi Print run duration 20-25000 sheets Resolution up to 70s grid integrated register punch DPX-RIP-Mate V8.x

Neuruppin Germany

Germany -

6818

Creo-Scitex

Lotem 800 V

2003

CTP systems

fully automatic external drum CtP exposure unit Infrared laser, 830 nm min. plate format 400 x 510 mm max. plate format 905 x 1130 mm Material thickness 0.2-0.3 mm Exposure speed approx. 10 plates/h at 100 l/cm Resolution continuously from 1524 to 3556 dpi with 1 printing plate carriage with Bacher 2000 Autoplate register punch (425 / 780 mm) with conveyor for online development machine Kodak XPO Station Mercury 1250 plate processor with stacker

Neuruppin Germany

Germany -

6835

Kodak

Lotem 400 Processless

2004

CTP systems

approx. 18,000 plates exposed External drum CtP exposure unit Infrared thermal laser 830 nm min. plate format in drum circumference 311 x 622 mm Max. plate size along the drum axis 229 x 750 mm Material thickness 0.15-0.3 mm manual record loading XPO workstation

Neuruppin Germany

Germany -

6876

Agfa

Avalon N 8-50

2008

CTP systems

Agfa Avalon N 8-50 S with multicassette MAL (5 x 100 disks loading capacity), a trolley internal plate punch Autoplate 425mm and 780mm Conveyor AT-T 8001 Plate development Agfa Elantrix 125HX (OEM Glunz & Jensen Quarz III 125) Plate stacker Highwater Rip Light source: GLV head with 512 channels Speed approx. 31 plates/h @ 2400 dpi Resolution 2,400 dpi / 4,000 dpi Max. plate format 1,160 mm x 940 mm Min. plate format 450 mm x 370 mm Plate thickness 0.15 – 0.30 mm

Neuruppin Germany

Germany -

53122

Heidelberg

Suprasetter 105

2009

CTP systems

8up thermal ctp Heidelberg Suprasetter 105 with MCL and Prinect Metashooter 11 Built in 2009 in good running condition Four thermal lasers 830nm with 8704 exposure hours Speed approx. 18 plates per hour Multicassette for 4 x 100 plates with paper Inner punch Heidelberg Autoplate size SM 102, CD 105 and XL 106 Advant PST 36 L panel stacker

Dabergotz Germany

Germany -

15277

Heidelberg

OHT-P

1980

Book printing

without ink fountain and ink rollers largest sheet 260 x 380 mm smallest sheet 40 x70 mm max. mold size 260 x350mm punching force 40 tons performance 5500 sheets/h 380 V 1.25 KW dead weight 1100 kg dimensions L1.68 x W1.24 x H1.85m 2 locking frames 2 heating plates

Dabergotz Germany

Germany -

6677

Heidelberg

OHT – TS

1961

Book printing

Heidelberg OHT – TS platen press for punching, grooving, perforating and embossing SN 130 986 N from 1961 including complete accessories for punching (7 locking frame bars and spaces) largest sheet 260 x 380 mm smallest sheet 40 x 70 mm max. mold size 260 x 350mm Punching force 40 tons Capacity 5500 sheets/h 380 V 1.25 KW Dead weight 1100 kg Dimensions L1.68 x W1.24 xH1.85m

Dabergotz Germany

Germany -

6673

Heidelberg

OHT

1962

Book printing

largest sheet 260 x 380 mm smallest sheet 40 x 70 mm max. mold size 260 x 350 mm Punching force 40 tons Capacity 5500 sheets/h 380 V 1.25 KW Dead weight 1100 kg 2 locking frames

Dabergotz Germany

Germany -

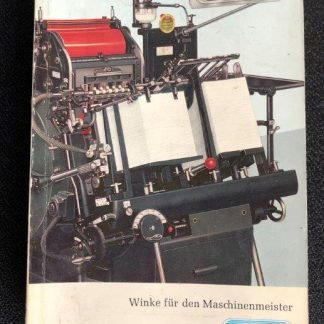

19308

Heidelberg

OHT Manual

1969

Book printing

May 1969 issue “Wave for the machine master” on original Heidelberg platen printing machines Perfect binding 152 pages

Dabergotz Germany

Germany -

7442

Heidelberg

OHT GTS

1965

Book printing

ORIGINAL Heidelberg OHT GTS A3 – platen punching machine with 3 closing frames and one closing plate in very good condition, built in 1965 Largest sheet format 34 x 46 cm Smallest sheet format 8.5 x 12 cm Max. sheet size 34 x 46 cm Max. punching size 32 x 45 cm Punching force 60 tons Max. hourly output 4000 sheets Weight approx. 2300 kg Dimensions 2.08 x 1.48 x 2.10 m

Dabergotz Germany

Germany -

7353

Heidelberg

GTS

1966

Book printing

Largest sheet format 34 x 46 cm Smallest sheet format 8.5 x 12 cm Max. sheet size 34 x 46 cm Max. punching size 32 x 45 cm Punching force 60 tons Max. hourly output 4000 sheets Weight approx. 2300 kg Dimensions 2.08 x 1.48 x 2.10 m

Dabergotz Germany

Germany -

6672

Heidelberg

GTP

1972

Book printing

with Heidelberg hot foil equipment 2-track 1 locking frame 1 heated honeycomb foundation largest sheet format 34 x 46 cm smallest sheet format 8.5 x 12 cm max. sheet size 34 x 46 cm max. punching size 32 x 45 cm Punching force 60 tons Max. hourly output approx. 4000 sheets Weight approx. 2300 kg

Dabergotz Germany

Germany -

6665

Heidelberg

Original Heidelberg GT

1966

Book printing

with inking unit with electromagnetic clutch 2 locking frames with special equipment 12 interchangeable gripper bridges for the central suction pickup of plastics, plastics, balsa wood and much more.

Dabergotz Germany

Germany -

15298

Heidelberg

OHT GT

1954

Book printing

– without inking unit – 2 locking frames Technical specifications: largest sheet format 34 x 46 cm smallest sheet format 8.5 x 12 cm max. sheet size 34 x 46 cm max. punching size 32 x 45 cm punching force 60 tons max. hourly output 4000 sheets weight approx. 2300 kg dimensions 2.08 x 1.48 x 2.10 m

Dabergotz Germany

Germany -

42165

Rietstack B.V

Model 2 Block Gluing Machine

Book printing

The Rietstack Model 2 Block Gluing Machine is a specialized piece of equipment designed for the book printing industry, specifically for block gluing applications. This machine streamlines the process of adhering book blocks, ensuring precise and efficient binding with consistent quality. Ideal for medium to large-scale printing operations, the Model 2 offers reliability and durability, making it a valuable asset for bookbinders and commercial printers. Its robust construction and user-friendly design enhance productivity while maintaining high standards of craftsmanship in book production.

Dabergotz Germany

Germany -

39058

Bograma

FR 550 Servo C

2008

Booklet machines

mobile automatic friction feeder Bograma FR 550 Servo C from 2008 for creating brochures and single sheets for offline operation with: Bograma individual modules, Bograma cutting systems, third-party units, etc. Technical data Format min. 148 x 75 mm with 2 vacuum belts Format min. 75 x 75 mm with 1 vacuum belt Format max. 550 x 320 mm Product thickness max. 5 mm Product thickness min. 120 grams / m2 paper Stacking table with movable side stops Stack ventilation with blown air Max. performance according to performance table Outlet height adjustable with spindle, 710 - 1050 mm Space required L 700 mm x W 1600 mm Weight approx. 300 kg Mobile with castors Outlet extension 250 mm Color: BOGRAMA Standard blue RAL 5023 Documentation: German Display language: German Electrical equipment Connection 230V / N / PE 50/60 Hz / 16A (Standard) Fuse 16

Dabergotz Germany

Germany -

7400

MKW

Rapid UT-12 B3 GS

2008

Booklet machines

Collating machine / brochure production MKW Rapid UT 12/B3/GS + SFT 350 Year of manufacture: 2008, Format: min. 10 x 14 cm, max. 35 x 50 cm Equipment: 12 stations gathering machine TFT touch operation Circulation toothed belt table with tandem function 1:1 and 2:1 timing Possibility of insertion at any station Carton change function at any station Adjustable tilting suction cups Side and front blowing air Max. stack height 700 mm Paper weight from 14 – 1000 g/m² Self-measuring electronic double and missing sheet control Stitching-folding-cutting unit SFT 350 Quick format adjustment Front trim with 6cm minimum trimming via upper and lower blades Blow-off air on the blade Adjustable pressing device 2 stitching heads Hohner 48/S PC-controlled collating with the MKW RAPID® UT series The circulating table principle enables tandem production and guarantees safe and smooth paper transport. Tandem Function: The tandem system is activated by a simple switch on the control panel. The parallel use of two stations with the same pressure enables up to 75% higher production output. Single function Standard collation in 1:1 operation with high page counts. MKW RAPID UT · Control System The use of state-of-the-art industrial PC technology ensures precise system control, digitally monitors assembly , and allows you to connect to your company's production control system. The operating system with a high-quality TFT display allows for straightforward machine operation. All settings are made using logically structured menus that are easily accessed on the display. Operator guidance and color-coded status indicators ensure optimal production processes. Saving and retrieving job configurations in seconds Combinable production counters for exact print runs and separation Standard special functions programmable at any station Standard quality control through missing and double sheet monitoring at each station Automatic rejection of faulty sets for non-stop operation Dynamic station selection for shortest setup times during job changes

Dabergotz Germany

Germany -

13442

MKW

Rapid SFT 350

2008

Booklet machines

Format: min. 10 x 14 cm, max. 35 x 50 cm Quick format adjustment Front trim with 6cm minimum trim over upper and lower blades Blow-off air on the knife Adjustable pressing device 2 stapling heads Hohner 48/S Stapling system with front cut L 1.50m x W 2.0m

Dabergotz Germany

Germany -

7385

Laconda

620 with HFc 33

1990

Booklet machines

Laconda 620 brochure line with stitching, folding and cutting unit Hfc 33 Type 91 Year of manufacture: 1990 10 collating stations approx. 30 cm filling height with double and missing sheet control Format max. 30 x 35 cm Format min. 10 x 10 cm Grammage: 14 – 1000 g/m² approx. 3,500 cycles / h Stapling-folding-cutting unit Hfc 33 Type 91 -with 2 Bostitch standard stapling heads -with front trim

Dabergotz Germany

Germany -

39087

Bograma

BSM 450 basic

2008

Booklet machines

BOGRAMA BSM 450 basic + UEB 550A + FR550 Servo C built in 2008 1 (one) BOGRAMA BSM 450 basic, built in 2008, automatic cutting and punching machine for contour and panel punching. Demo video at https://youtube.com/shorts/zxGgEdwIAww?feature=share with the following tools: – 1 x interchangeable parts set BSM 450 – 2 x additional panels (i.e. possibility to cut to 3 panels) standard with 4mm cutting knife – 1 x strip steel tool setup for BSM 450 1 (one) mobile transfer BOGRAMA UEB 550 A with clocked blowing air and stripping station 1 (one) friction feeder BOGRAMA FR 550 Servo C for feeding brochures and single sheets for offline operation with: Bograma individual modules, Bograma cutting systems, third-party units, etc.

Dabergotz Germany

Germany -

7314

Horizon

Stitch Liner 5500

2005

Booklet machines

2 collating towers VAC 100 a+m with 10 stations each (20 stations in total, expandable to 60) 1 additional blower EAB-100 ACF 30 collecting and folding unit SPF 30 stapler (2 stapling heads Hohner 43/6 S) HTS 30 3-side trimming with 8mm separating cut device Chip extraction PK 30 Pre-selection counter with offset delivery

Dabergotz Germany

Germany -

7323

Duplo

System 5000

2006

Booklet machines

Outfeed vibrator right-hand tower with 10 stations DC 10/60 suction air system Duplo 5000 with touch control LS1 transfer bridge DBM-400 booklet maker with two Hohner stitching heads 48/5 S DBM-400 trimmer DBM-LS long stream delivery

Dabergotz Germany

Germany -

7329

Duplo

DSF 2000-120

2008

Booklet machines

Set-by-set processing of digitally printed sheets with and without cover insert, consisting of: – DSF 2000 Sheet Feeder – DBM 120 Stitcher/Folder – DBM 120 T Front Trimmer Feed system: Suction belt Paper formats: Length: 279 to 450 mm, Width: 210 to 320 mm Pre-stack height: Paper tray A: 200 mm, Paper tray B: 60 mm Speed: max. 150 sheets/minute The DSF-2000 digital sheet feeder with its two-station feeding system is the key to optimal finishing of digital prints. One station is for brochure covers and/or slip sheets, and another station for digitally sorted printed inside pages. Operation is via the sheet feeder's menu control. The entire booklet production line automatically adjusts to the format loaded into the sheet feeder. The sheet sets assembled by the sheet feeder are collected, stapled, and folded in the FKS/Duplo DBM 120-SxS booklet maker. The trimmer then ensures a perfect finish for your products. Standard equipment: Paper turning device

Dabergotz Germany

Germany

The World of Print at your Fingertips

The Machine Dalal Mobile Apps

Download our Machine Dalal App Regular updates from our magazine with illustrations, innovations , commodities, history, media, art and a whole lot more from the magnificent world of Print.

Get the App

Login

Login