Allforprintmarket.

Allforprintmarket.com is your trusted partner for used printing & packaging machinery. With expertise in buying and selling, we’ve completed trades in 40+ countries, focusing on client needs, professionalism, and detail from first contact to final transaction.

- Location Iasi | Romania

- Member Since 2025

Scan & Share

View :

-

Zechini

Roby One

2005

Case makers

Used Zechini automatic gluing and mounting machine Working format: 50 x 70 mm Case making Mounting Case lining

Turkey

-

Honeywell

scanner and calender corrugated cardboard

Corrugated Box Machines

Used Package of machines for corrugated cardboard Paper width manufactured: 5400 mm Face length of the rolls: 5545 mm top roll; 5765 mm bottom roll Center to center distance: 6745 mm top roll; 7430 mm bottom roll Diameter of top roll: 1016 mm Diameter of bottom roll: 800 mm

Romania

-

Theisen & Bonitz

Collator

2004

Gathering and collating

Used Theisen & Bonitz equipment 10 stations Maximum format: 35 x 50 cm Minimum format: 6.5 x 10 cm Paper grammage: 18 - 1000 g / sqm Maximum speed: 3300 cycles/hour TB sprint 303 QSM 2006 Open format: max 35 x 50 cm/ min. 6,5 x 15,5 cm Smallest brochure length: 6,5 cm Maximum speed: 2200 cycles/hour QSM 2 x Hohner Universal Frontal cutting

Romania

-

Kornit

Breeze 921

2020

Digital Press

Digital textile printing machine 2 white heads to be replaced CYMK print heads + two white heads Maximum print size: 350 x 450mm Pre-treatment included Disconnected in December 2024

France

-

MBO

T460-1-46/4-F

2013

Folding Machine

MBO A56-DC-24 Maximum format:460 x 660 mm Minimum format:60 x 110 mm Paper Weight: 30 -180 g/sqm Minimum fold: 32 mm

Romania

-

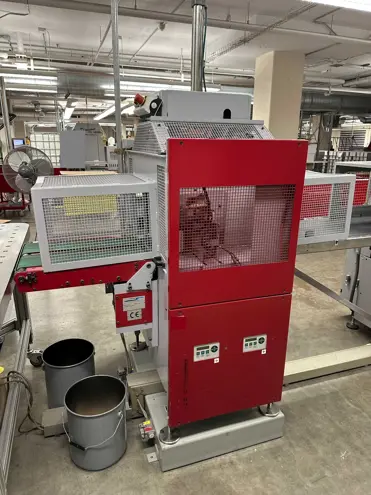

DEM

Sealer & Heat Tunnel

1993

Wrapping Machine

Semi-Automatic L-Sealer: Product size: 2100 x 650 mm(Length x Width) Automatic Conveyor Roller Holder Heat Tunnel: Max product size: 650 x 650 x 600 mm (Length x Width x Height) Adjustable Temperature Adjustable Conveyor

United Kingdom

-

DCM

Babycat

2006

Flexographic equipment

No slitting, only rewind Maximum web width: 400mm Maximum unwind and rewind reel diameter: 610mm Maximum production speed: 400 m/minute Bi-directional operation Double web guide 2 synchronized motors

Romania

-

OCE

Arizona 360 GT+WIO

2012

Digital Press

UV flatbed printer Table size: 1.25 x 2.5 m Maximum print speed: 35 sqm/hour Maximum Media Thickness: 48 mm

Germany

-

Mimaki

UJF-3042Mk II

2017

Digital Press

2 machines 14.800 & 15.200 working hours Kebab 360-degree direct printing on cylindrical products Maximum Print resolution: 1200 x 1200 dpi Maximum print width: 300 mm Maximum print length: 420 mm Material Thickness: 153 mm

Hungary

-

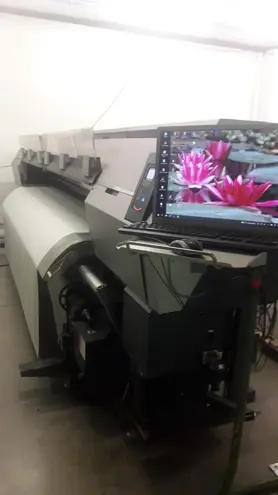

Roland

Truevis SG-540

2017

Digital Press

Printing time: 1900 hours Cutting time: 601 hours Printed area: 5400 sqm Width: 210 - 1371 mm Maximum thickness: 1.0 mm with liner for printing Maximum Roll outer diameter: 210 mm Maximum Roll weight: 30 kg Maximum Printing/cutting width: 1346 mm

Hungary

-

Xerox

Versant 2100

2019

Digital Press

Produced in 2019 Installed in 2020 Resolution : 2400 x 2400 dpi Maximum Sheet Size: 330 x 488 mm Minimum Sheet Size: 139 x 182 mm Maximum Print Area: 326 x 482 mm Paper Grammage: 52–300 g/sqm

Lithuania

-

KBA

SRO 2

1997

Sheet Fed / Offset

2 colors Maximum format: 52x72 cm Maximum speed: 15000 sheets/hour 6,3 million impressions Alcohol dampening Technotrans

4

Czech Republic

-

Redefining Customer Acquisition in Machinery and Equipment Sales

Plans, Pricing & Subscriptions

-

Heidelberg

GTO 52-2 ZPN

1991

Sheet Fed / Offset

Maximum sheet format: 360x520 mm Minimum format: 105x180 mm Maximum printing area: 340x505 mm Printing speed: 3.000 – 8.000 sheets/ hour Numbering device Good cylinders condition No damages Documentation Tools

2

Hungary

-

Adast

Dominant 516

1994

Sheet Fed / Offset

1 color Maximum format: 38x52 cm Maximum print area: 37x51,5 cm Maximum speed: 11.000 sheets/hour

1

Romania

-

Mutoh

Valuejet 1638UR Mark II

2021

Digital Press

Maximum width: 1625 mm Minimum width: 185 mm Resolution: 1440x1440 dpi Maximum speed: 22.7 sqm/hour Counter: 18.000 sqm Double CMYK configuration Mint Condition

Albania

-

DuPont

Cyrel Fast 1000TD

2007

Thermographic machines

Plate making system Maximum plate width: 900 mm Minimum plate width: 254 mm Maximum plate length: 1,200 mm Maximum Plate thickness: 2.84 mm

Czech Republic

-

Maxcan

Coral 4G

2015

Digital Press

CMYK 4 x Epson DX5 UV Flatbed printer Format: 1x1,5m Vacuum with 3 areas

Spain

-

Hans Gronhi

GH 525

2011

Sheet Fed / Offset

Used Hans Gronhi printing press Minimum format: 14.8x10 cm Thickness: 0.04 - 0.4 mm Off press control system with closed loop color control CIP3 file technology Pneumatic plate clamping

5

United Kingdom

-

Halm

Superjet JP6000

2000

Envelope manufacturing equipment

Used Halm envelopes printing machine Excellent condition, ready for production Maximum sheet size: 324x457 mm Minimum sheet size: 82x108 mm Maximum printing format: 305x457 mm Working speed: 60.000 envelopes/hour High pile feeder unit Digital Display Baldwin Circulator

Romania

-

Heidelberg

Stahl TD 112

2003

Folding Machine

Configuration 4 + 4 + 2 3 groups: 4 pockets + 4 pockets + 2 pockets 1 knife Vfz d 52 Max sheet size: 1120x1650 mm

Italy

-

Mimaki

TS500P 3200

2017

Digital Press

Counter: 200.000 sqm 12 On-demand piezo heads (4 heads alternating) Print resolution: X-axis: 360/540/720/1080 dpi; Y axis: 360/540/720 dpi Maximum media width: 3000 mm Maximum printing area: 3290 mm Maximum media weight: 130 kg Maximum media thickness: 0.2 mm On pallets, ready for delivery

Poland

-

Svecia

SPM Printmaster

1985

Screen printing

Format: 880x1250 mm 3/4 machine with gripper system and fixed printing table This makes it much faster than a printing press with a mobile printing table, with the same high level of accuracy and print quality Infinitely and independently adjustable squeegee and flood squeegee speed Infinitely adjustable gripper/throughput speed Pneumatic squeegee pressure compensation Pneumatic frame attachment Year of construction: 1985 Svecia Power Jet Dryer SPJD 3 sections dryer 2 x warm (up to 70 degrees) 1x cold air Connection 400V / 115 amps Air flow: 3000m³/h Belt speed 1.5 – 35 m/min Year of construction 1997 Svecia stacker SAP-A 880 x 1250 mm Year of construction: 1997 The entire line is approximately 12.80 meters long

Germany

-

Stahl

T 36.4/KB

1993

Folding Machine

Flat Pile Feeder Folding Type: 4 buckles - 1 knife Minimum format: 80 x 100 mm Maximum format: 360 x 650 mm Paper weight: 40 – 250g/sqm Maximum pile height: 580 mm Speed: 10 – 160 m/minute Diameter of folding rollers: 32 mm Delivery Stream Delivery Compressor Manuals Available immediately Working condition

Greece

-

Flag

FL 115

Guillotines

Maximum width: 115 cm Programs Air table Hydraulic action Machine in production

Romania

-

Sitma

SM15

2008

Envelope manufacturing equipment

Sitma E-111 Sitma 111-P Sitma 111-6E Sitma TR0120C Maximum Speed: 15.000 cycles/hour (C6) Format: C6, C6/C5, C5, C4

United Kingdom

-

Sitma

C 905

1991

Packing machines

Counter: 3034 hours Sitma 711 Speed: 11.000 pieces/hour

Portugal

-

Accraply

ShrinkMaster S2000

2015

Flexographic equipment

Superb shrunk finish with Filled or Cold Containers Virtually Dry shrinking Fully Insulated & preheated Chassis Unique Coaxially piped shrinking nozzles to minimize condensation 12 heating areas split into two zones for complex shapes Stainless Steel Prepset & Extraction Dry Steam tunnel Minimum Conveyor Height: 900 mm Maximum Conveyor Height: 1000 mm Minimum Container Height: 50 mm Maximum Container Height: 300 mm Minimum Container Diameter: 20 mm Maximum Container Diameter: 120 mm Pressure: 5 Bar Steam Requirements: 100 - 200 kg/hour

Turkey

-

Accraply

Stanford DM12

2016

Flexographic equipment

Automatic inspections for seam integrity, solvent presence and splice/flag detection. Two-motor smart AC Vector drive system On-board drive-based PAC Control Internet-based remote diagnostic with WiFi capability Stanford DM12 Shrink Sleeve Inspector Manual inspection button with return-to-defect Intuitive touchscreen controls with unlimited recipes Electronic rewind oscillation up to 20 mm Cantilevered compact design Reversible over/under winding Minimum Layflat Width: 50mm Maximum Layflat Width: 305 mm Maximum Web Speed: 500 m/minute Maximum Unwind Diameter: 610 mm Maximum Rewind Diameter: 610 mm Tension: 0.26 Kg/Cm Total Minimum Tension: 1.58 Kgf

Turkey

-

Muller Martini

Static Blocker 6214

2003

Perfect Binder and Gatherer

The Muller Martini Static Blocker 6214 is a high-performance blocking unit designed for perfect binding and gathering applications in the printing and publishing industry. As part of the Perfect Binder and Gatherer category, this machine ensures precise static control during the binding process, enhancing production efficiency and quality. Manufactured in 2003 and very well maintained, the Static Blocker 6214 is ideal for commercial printers, book manufacturers, and packaging producers seeking reliable performance in high-volume binding operations.

United States

-

Remak

RE 2x80

2002

Flexographic equipment

Used flexo printing machine Maximum width: 800 mm 2 colors 2+0; 1+1 Materials: PE, PP, BOPP, CPP, PET, PVC, AL, Paper Manual control for foil unwinding Printing cylinders: 32-2 pieces, 35-2 pieces, 36-2 pieces, 40-2 pieces, 45-2 pieces, 50-2 pieces, 55-2 pieces, 60-2 pieces.

Romania

-

Duplo

System 5000

2007

Saddle Stitcher

2 towers DBM 500 Counter: 10.5 million DBM 500T Counter: 10.2 million DC 10/60 Counter: 9.8 million DC 10/60 Counter: 2.9 million

Poland

-

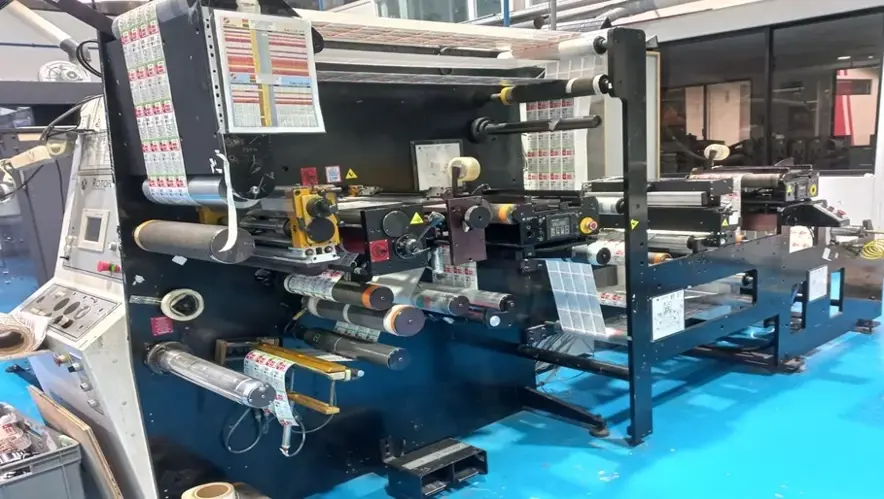

Arsoma

EM 220

1991

Flexographic equipment

8 printing units: 4 colors UV in production, the other units dismantled in the warehouse(from one year ago) 4x dryer with warm air 3x UV dryer 1x UV drying double IST lamp (varnishing) 8x ink pump 2x die-cutting unit (magnetic cylinder die-cutting) Knife unit for side cutting (shear knife) Maximum web width: 220 mm Core diameter: 76 mm Maximum Outside diameter 1000 mm (infeed) Maximum Outer diameter 720 mm (outlet) Pile stacking device Column lifter for magnetic cylinder

Poland

-

Rotoflex

VLI 330

2007

Flexographic equipment

Roll-to-roll label inspection and rewinding machine Maximum web width: 330 mm Maximum speed: 305 m/minute Unwind Capacity: 711 mm Rewind Capacity (Single-Spindle): 457 mm Rewind Capacity (Dual-Spindle): 406 mm Configuration: Rewind shaft Unwind shaft Web guide/Splice Table Draw station Crush Knife unit Shear Knife unit Razor blade unit Jog & Rewind deflate pedal Auto web gripper Unwind adjustable splice table Strobe light Front inspection C3/URC counter Air control panel Web gripper activation switch Leveling foot Side job Pedal Roll End Sensor Rewind direction change switch

Ecuador

-

Shm

HB 520A

2022

Calendar production

Semi-automatic double wire binding machine Wire Specifications Diameter: 1/4" - 7 /8" Pitch: 3:1" & 2:1" Handling of Double Wire: Automatic cutting, insertion& closing. Skip binding up to 6 steps allowed. Maximum Paper Width: 520 mm Maximum Binding Width: 507 mm Minimum Binding Width: 75 mm Working Speed: 1,000 - 1,500 cycles/ hour Size of Worktable: 660 x 300 mm Air Pressure:6 - 8 bar

Romania

-

Rilecart

TP-480

2007

Calendar production

Semi-Automatic Double Loop Wire Binding Machine Maximum binding length: 48 cm Speed: 1.000 cycles/hour

Romania

-

Carint

Gemini 1587

1987

Flexographic equipment

Printing Repeat: 370 -780 mm Maximum working width: 1100 mm Minimum working width: 600 mm 6 colors Maximum speed: 100 m/minute Good running Condition

Malaysia

The World of Print at your Fingertips

The Machine Dalal Mobile Apps

Download our Machine Dalal App Regular updates from our magazine with illustrations, innovations , commodities, history, media, art and a whole lot more from the magnificent world of Print.

Get the App

Login

Login