Popular Brands Or view all

Web Machinery for Sale | Preowned & Preloved

Solna

D30

1992

Web

Cut-off: 630 mm Tabloid size N. 4 printing units with 1+1 section Remote control for ink & register FOLD unit TECNOTRANS chiller LAMAL automatic reel rewinder Delivery with belt, stacker Muller Martini Printing capacity: n. 8 pages in 4 colors n. 16 pages in 2 colors n. 32 pages in 1 color Including as spare: N. 2 printing units with 2+1 section N. 1 printing unit with 1+1 section N. 1 Solna D25 printing unit with 1+1 section

Terni Italy

Italy

Manroland

ROTOMAN

2011

Commercial / Heatset

Cut-off: 598,5 mm Web Width: 965 mm Mech. Speed max.: 55.000 rev./h Equipment: 1 MEGTEC reel splicer, 50" Roll 1 MAN Roland Infeed Unit 1 QTI Web guide System 4 ROTOMAN double printing units BLANKET TO BLANKET - PECOM Press control - PPL semi automatic plate changer - motorically adjustable circumferential and side registers - BALDWIN Automatic Blanket washing device - Hydromix dampening unit - TECHNOTRANS Gamma.a Refrigeration Unit - automatic central oil lubrication - AC Drive Sytem 1 web catching device 1 paper guiding system with rollers and paper break sensors 1 MEGTEC DLC 2100 hot air dryer with integrated After Burner 1 MANROLAND Chill unit with 5 chill rollers 1 QTI Color register control 1 QTI Cut-off register control 1 MAN Roland Folder superstructure with Former fold & 4 angle bars 1 PLANATOL CombiJet gluing device 1 WEKO silicon applicator 1 Manroland Model PFJ 16-50 pin folder in 1:2:3:3 system with: - 2nd. Cross Fold - DELTA and Double parallel Fold 2 Deliveries 1 Plate Bender

Oslo Norway

Norway

KBA

COMPACTA C 618

2008

Commercial / Heatset

Cut-Off: 578 mm Cylinder circumference: 1156 mm Web width: 1450 mm Printing area max.: 572 X 1445 mm Paper Grammage: 40 - 130 g/m² Speed max.: 45.000 RPM Direction: Left to Right Equipment: 1 KBA Pastomatr RC Splicer max. reel diameter 1270 mm Patras A auto reel loading 1 KBA EZW 1450 Web Infeed E&L Web guid 4 KBA C 618 Printing Units KBA Opera ( DriveTronic, ErgoTronic, ColorTronic) KBA LogoTronic professional Minigap Technology Semi automatic Plate change VARIDAMP dampening TECHNOTRANS Delta.d 300W Refrigeration Unit BALDWIN IMPACT Blanket wash TECHNOTRANS Auto ink supply 1 Graficontrol CR25 1 Graficontrol CR8-TS 1 Graficontrol Densiweb 1 VITS ROTOLINE Sirius Hot Air Dryer integrated Afterburner 1 BALDWIN Web Catcher 1 KBA KWS 4 Roll Chill Unit 1 WEKO WFG 2.4 Silicon applicator 1 Eltex Webmoister 70 1 E&L Web Guide 1 KBA Folder Upper Structure Slitting Unit with two knives Two pairs of air loaded angle bars Two Compensators Two air loaded Formers 1 HHS Autosys Vario gluing system 1 KBA V5-1156 Folder production: A/3-A/4- double parallel and DELTA 1 Axima i.cool Aquacenter S Cooling Center 1 FALK Drucktech 200 water preparation

Oslo Norway

Norway

KBA

COMPACTA C 215

2002

Commercial / Heatset

Cut-Off: 620 mm Web with max.: 1000 mm Web width min.: 420 mm Printing area max.: 614 X 995 mm Paper Grammage: 30 - 130 g/m² Speed: 50.000 RPM Direction: Left to Right Equipment: 1 KBA pastostar RC Reelstand max. reel diameter 1270 mm Patros auto reel loading 1 KBA EZW 1000 Infeed E&L Web guid 5 KBA C 215 Printing Units Direct Drive Minigap Technology Fully automatic Plate change on Unit 1 & 2 (flying plate change capability) Semi automatic Plate change on Unit 3,4 &5 Oxy-Dry Kombi Blanket wash Auto ink supply 1 VITS OTS Sirius Hot Air Dryer integrated Afterburner 1 KBA Web Catcher 1 KBA KWS 3 Roll Chill Unit 1 WEKO WFG 2.4 Silicon applicator 1 E&L Web Guide 1 KBA Folder Upper Structure Slitting Unit with two knives Two pairs of air loaded angle bars Two Compensators Two air loaded Formers 1 KBA 16 page Pinless Folder production: A/3-A/4- double parallel and DELTA 1 KBA 8 page stacked Folder 2 X 8 page A/4 1 Remote Folder Console 1 Planatol Gluing System 1 Grafikontrol CR20 automatic Color Register Control 1 Grafikontrol CR8 automatic Ribbon- Cut-off Register 1 GRAFIkontrol Densiweb - Automatic Closed Loop Color Control 1 Technitrans Delta d 160W Refrigaration/Recirculation for Dampening 1 KBA Main Control Desk 2 KBA Color Desks 1 KBA Drivetronic Drive and Control System Rexroth variator replaced in 2021 KBA Opera 1 Sulzrer Central Chilling System 1 Berth AKA 200M Plate Bender 1 AKA 200S Blanket Bender 1 Plate punch 1 Set of Manuals and Drawings 1 All C215 Spare Part & Rollers 1 Noise Enclosure 1 Small Forklift Truck with reel Clamps (STILL R70-30T Post Press Equipment: 1 Exit Conveyors 1 RECMI Combined Bump/Flow Turn 1 Waste Copy Conveyor 1 Rotaschneider Rotary Trimmers 1 Rotoschneider Bump Turn 1 Gämmerler KL 540 Comensating Stacker 1 RECMI HC610 Log Stacker and Palletizer Condition: Excellent (8)

Oslo Norway

Norway

Nilpeter

FA-3

2007

Flexo

Nilpeter FA-3, 2007 MODULAR 13" MULTI - SUBSTRATE FLEXO PRESS INFEED MODULE Web cleaner Corona 9 Flexo unit 9 UV Drying GEW (2018) 2 Hot-air Drying Rail-system Turnbar De/Re Lamination 2 Cold- Foil UV Lamination Sheeting unit 2 Screen unit Unwind Print cylinder 103 Anilox 40 Magnetic 10

Hude Germany

Germany

Nilpeter

FA-6

2015

Flexo

Equiped for printing flexible packaging, laminates Web width max 570mm Printwidth max 560mm Configuration: Unwind (Ø1000mm, max 350kg) Infeed with Teknek webclean + 2xcorona 9 print units for flexoprint with GEW UV incl ink pumps on each printing unit UV tower for secure UV curing before lamination 1 MP-Unit (multi purpose) for Solvent & Water Based 2-component inks, vanishes etc Incl Viscosity Control Inline lamination (dry and wet lamination) Converting module Inspection Video 16" single die for labels with Kocher & Bech GapMaster (NB the width only 16") Rewind unit (Ø1000mm, max 350kg) (on rails De/Relam for unit 1+2, 2 x towers (unwind + rewind) for coldfoil) 17 sets of sleeves for plates Everything is in excellent condition 101, 112, 126, 130, 134, 138, 140, 142, 144 17 Anilox cylinders in excellent condition Additional ink chambers (Cleaninking) The machine are fitted with a ATEX exhaust which are a "must have" when running SB/WB lamination (2-component)

Hude Germany

Germany

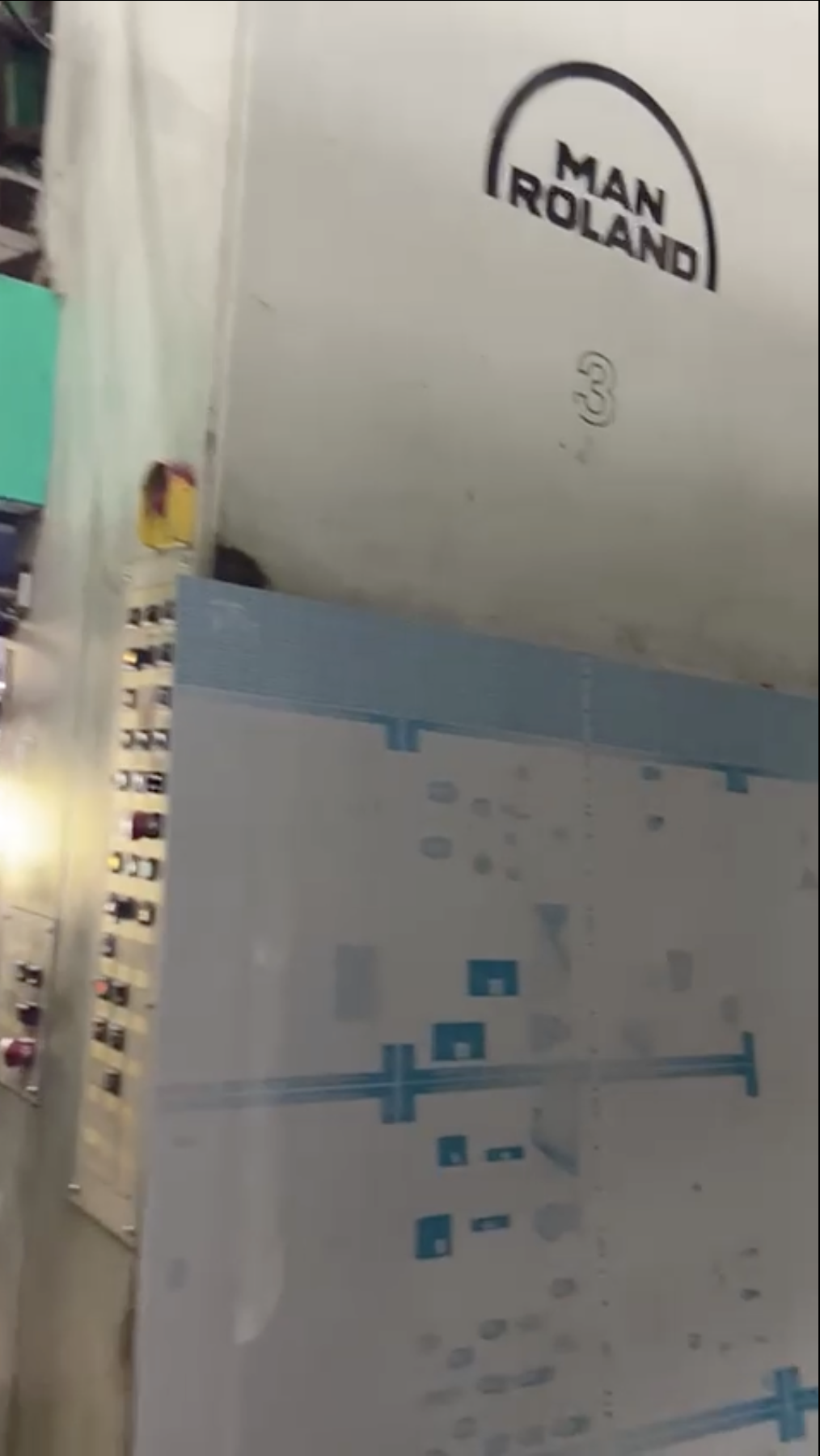

Manroland

CROMOMAN

2022

Newspaper / Coldset

Industrial Scale - Digital Finishing Solutions Your benefits ■ Industrial design by manroland Goss engineering based on web offset modules ■ Outstanding productivity ■ High reliability and low production tolerances ■ Best-of-class variable cut sheet separation within belt sections ■ Dynamic change of pagination and book structure without standstill “on the fly” ■ Dynamic change of cut-off length for all folding options ■ Fully JDF/JMF-controlled device for setup time down to 3 min with format change ■ Variable Broadsheet sections for individual newspapers (FoldLine) ■ Variable Tabloid page numbers for personalized issue (FoldLine) ■ Additional features available FoldLine: cylinder-stitched tabloid newspapers, booklets or book signatures ■ Variable book signatures page numbers with flexible former positioning (FormerLine) ■ Additional features available FormerLine: book block finishing with RIMA collator. Final format 175 x 245 mm 75 x 245 mm 137 x 135 mm 175 x 245 mm 150 x 215 mm 170 x 240 mm 125 x 190 mm Folding format 190 x 260 mm 190 x 260 mm 137 x 152.4 mm 190.5 x 260 mm 165 x 230 mm 180 x 225 mm 137.5 x 205 mm Folding schematic double parallel double parallel gate fold double parallel single sheet single sheet single longitudinal fold Auxiliary gluing 2 point -/- -/- -/- -/- -/- -/- Pages per signature 8 8 6 8 2 2 4 Web width 760 mm 760 mm 275 mm 762 mm 165 mm 180 mm 275 mm Paper 90 gsm, 52 gsm, 80 gsm, 160 gsm, 60 gsm, 100 gsm, 80 gsm, 1,5 volume newspaper CVG DNS High Z-Bond CVG CVG Digital HS Alster Digital Snowprint Digital HS Speed Inkjet Classic Digital HS

Kuala Lumpur Malaysia

Malaysia

Dartwyler

Gravostar

1997

Gravure / Rotogravure

Shafted Maximum face length: 2100 mm Maximum total length: 2200 mm Minimum Circumference: 250 mm Maximum Circumference: 1300 mm Hollow Maximum face length: 1850 mm Maximum total length: 1850 mm Minimum Circumference: 250 mm Maximum Circumference: 1300 mm Engraving head capability: 54-100 Screen/4000 Hertz

Turkey

CEMB

ZE 1000 TCGV

2004

Gravure / Rotogravure

Horizontal balancer machine Weight of the rotor: 10-1000 kg Maximum weight for each support: 550 kg Maximum weight of symmetric rotors balanced occasionally: 1100 kg Percentage reduction of the unbalance with just one spin, with standardized rotors, after dimensional calibration: 95% Unbalanced reading time with rotor at steady speed: 5 sec Diameter of rotors for resting of belt: 50-500 mm Diameter of rotors journals with standard equipment: 10-100 mm Minimum distance between centre lines of the bearings: 150 mm Drive: 4.5 kW Motor speed: 3000 revolutions/minute

Turkey

Dartwyler

Polishmaster 2310

2002

Gravure / Rotogravure

SHAFT Maximum Face length: 2200 mm Maximum total length: 2800 mm Minimum circumference: 450 mm Maximum Circumference: 1200 mm HOLLOW Maximum Face length: 2200 mm Maximum total length: 2200 mm Minimum circumference: 450 mm Maximum Circumference: 1200 mm

Turkey

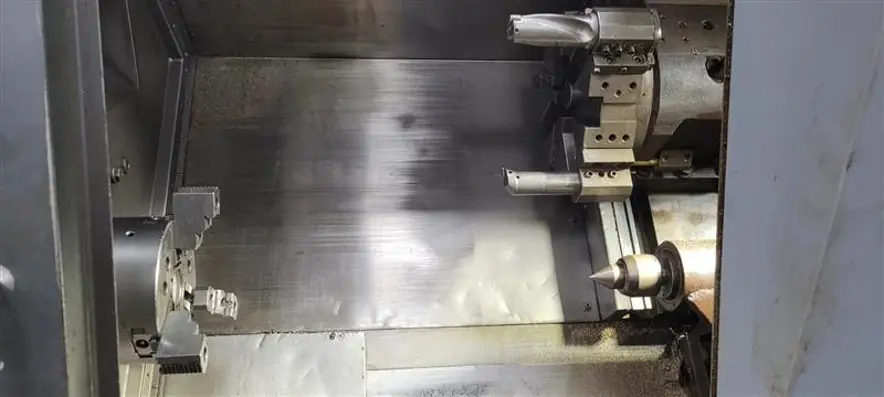

Accuway

UT 200

2009

Gravure / Rotogravure

CNC Lathe Swing over Z cover: 2,39/518 ln/mm Swing over X Cover: 12,5/ 318 ln/mm Maximum cutting diameter: 13,78/350 ln/mm Maximum cutting length: 22.44/570 ln/mm Spindle speed: 4500 rpm Power chuck diameter: 8”/210 ln/mm Spindle hole diameter: 2.44/62 ln/mm 8 tools Total size square: 1,0/25 ln/mm Total size bar: 1, 26/32 ln/mm

Turkey

Harris

M 300

1989

Commercial / Heatset

Harris M 300 - Heatset Web Printing Presses 1989 Cut off: 630 mm Colors: 4 x 4 Maximum width: 965 mm Splicer Butler ME 2000 MEC Dryer Sigma plus 60 4d Folder, Tabloid, Parallel Folding Maximum Speed: 35.000 cycles/hour Dampening Alcohol Brush roll Dampening system Manual Plate Loading Refrigeration Baldwin

United Arab Emirates

Goss

Metrocolor

1994

Commercial / Heatset

5 printing units cut off: 560 mm Full-color front and back Quad Tech automatic color registration Two-tone units, front and back Goss Sovereing Goss CT45 reelstands Tolerans in-line fastener Gammeler 4 towers Folder

Mexico

Topking

OCC 1886

2010

Gravure / Rotogravure

Swing over table: 450/ 650 mm Maximum grinding diameter: 420/620 mm Wheel speed: 33 m/s Wheelhead-X Axis: Maximum movable distance: 350 mm Feedrate: 0.001-2000 mm/minute Rapid Feedrate: 4000 mm/minute Wheelhead-Z Axis: Maximum movable distance: 2750 mm Feedrate: 0.001-2000 mm/minute Rapid Feedrate: 4000 mm/minute Workhead maximum speed: 350 rpm Table rapid feedrate: 6 m/minute

Turkey

Doosan

Puma 400 LB & 400 LC

2006

Gravure / Rotogravure

CNC Lathe Swing over bed: 700 mm Maximum diameter: 550 mm Travels: X axis: 362 mm Z axis: 1.105 mm 10 tool stations Bearing diameter(front): 180/240 mm Boring bar diameter: 50 mm

Turkey

Harris

M1008 BE

1993

Commercial / Heatset

32 pages press 8 printing units Cut-off: 22.75” Width: 38” RGS IV Quad Tech Record Control Stacker Muller Martini 327 Planatol Optimatic Combijet 5 DT gluing system Stacker Gammerler SH 700 (year 2010) Gammerler PL500 palletizer (year 2010) Scheffer varnish Scheffer online die cutter Speed: 50,000 x hour

Mexico

Leadweal

LTC 35 CLV

2011

Gravure / Rotogravure

CNC Lathe Maximum Swing: 800 mm Swing over cross side: 540 mm Maximum turning diameter: 600 mm Maximum turning length: 2030 mm Z axis: 2100 ln/mm X axis: 300+30 ln/mm Spindle speed: 2000 rpm 12 tools

Turkey

Worldly

WRP AS 1200 8C

2013

Gravure / Rotogravure

Rotogravure printing machine Printing material: OPP 20-40 microns, PET 12-30 microns, PE 25-40 microns, CPP 30-60 microns, PVC 35-50 microns, Nylon 15-30 microns Maximum printing width: 120 cm Printing cylinders circumference: 40-100 cm Printing cylinder width: 95-125 cm Maximum speed: 200 m/minute Working speed: 180 m/minute Maximum unwinding diameter: 600 mm Maximum rewinding diameter: 600 mm Aluminum guide roller: 9-130 cm

Mexico

Manugraph

Cityline 546

2011

Commercial / Heatset

Manucolor Quadtech Autopaster integrated Twin 4 x 4 Hi tower Folder 2:2:2 book quarter folder & double parallel Chiller tank Electrical panel with AC Console

India

Uteco

Onyx 876 GL

2006

Gravure / Rotogravure

Maximum Width: 1450 mm Flexo CI Gearless 8 Printing Units Drying System: LPG Gas Repeat: 380 – 800 mm Mechanical Speed: 365 m/minute Doctor Blade Chamber Maximum Material width: 1410 mm Unwinder Turret - 800 OD Rewinder Turret- 800 OD Sleeve Anilox Rollers HMI Control unit for Sleeve change/Temperature/Tension, and register 3 x keypad controls Camera ReVision BST Edge guides for the rewind and unwind Chill Roll unit with Corema Chiller unit Allen Bradley PLC Control Techniques Drives for Cliché and Anilox Software upgraded in 2023 Gas drying system with an automatic air recirculation system Anilox- 4x475 ,4x320, 2x260, 1x200, 1x220, 1x140, 2x120, 2x160, 1x180, 2x100, 1x80 Sleeves-16x380, 8x400, 8x410. 8x420, 10x430, 8x450, 9x490, 8x500, 8x510, 8x520, 16x530, 12x600,8x570, 8x580, 8x600,16x620, 8x630, 8x640, 8x650, 9x660, 8x670, 8x690, 8x700, 8x750, 8x790, 8x800

South Africa

Heidelberg

GOSS M 130

2000

Commercial / Heatset

Cut-off: 578 mm Web Width: 965 mm Mech. Speed: 40.000 rev./h Specification: Contiweb SH 40-OP-102 automatic splicer for one web HEIDELBERG/HARRIS T23 infeed Unit with web aligner 6 HEIDELBERG/HARRIS Double Printing Units Telecolor II remote ink control System Duotrol Dampening System Omnicom Automatic Blanket washing devive AWS Ink levelers 3 Control consoles 1 Contiweb 7.0 Ecoweb dryer with Afterburner 1 QTI RGS Color register system 1 QTI Cut-off controls 1 QTI Web guide 1 Chill Unit with four chill rollers 1 Silicon applicator 1 HEIDELBERG/HARRIS Folder Superstructure with 2 turner bars Slitting- and perforation shaft Former Folder 1 HEIDELBERG/HARRIS Combination Folder Broadsheet - Tabloid - DELTA Fold - Double Parallel Fold 1 VITS QRO Rotocut Sheeter

Oslo Norway

Norway

Harris

M 300

1987

Commercial / Heatset

1 EnkIe double Roll Splicer 1 HARRIS Infeed Unit 1 E & L web guide 4 HARRIS Printing Units Alcohol Film Dampening Refrigeration Unit Ink Unit Temperature control 2 Operator consoles Main and auxiliary command 1 QTI automatic color registration control system 1 QTI cut control 1 Band break detection package 1 Main press drive system 1 TEC Dryer 1 HARRIS Chill Rolls, 4-Rolls 1 Silicone Applicator 1 Folder superstructure with 4 angle bars Former Fold and perforation- and Slitter bars 1 HARRIS JF-44 combination folder 1 Sheeter

Oslo Norway

Norway

Manroland

LITHOMAN IV -72

2003

Commercial / Heatset

ContiWeb Splicer Type FMR3-16-203L Infeed Unit with E&L Web aligner MAN Roland Web catcher 4 Double Printing Unit Blanket/Blanket 3 Control console Automatic Blanket Washing devices -for 8 Printing Units TECHNOTRANS Refrigeration Unit 1 VITS Dryer with integrated after burner 1 Chill Unit with 5 Chill rollers 1 WEKO Silicon applicator 1 PLANATOL Gluing with 7 gluing heads and softening device 1 QTI cut-off register control 1 QTI color register control 1 E&L Web aligner 1 MAN Super Structure 2 Former fold - angle bars - Perforation- and Slitting shafts 1 MAN Folder PFI/3-2, system 2:3:3:3 1 additional Folding Group, (Piggyback Folder) on top of the main folder Quarter Fold, DELTA Fold Double parallel Fold 2 Deliveries 2 Conveyor in two levels 1 CIVIEMME Stacker Type ST 420 Log Stacker 1 CIVIEMME Stacker Type ST 280 DX-SX

Oslo Norway

Norway

Harris

GOSS M600

2004

Commercial / Heatset

1 Contiweb SH40-CI-1020 splicer, integrated power supply with QTI web guide 4 Heidelberg Printing Units Blanket to Blanket 1 Main press drive system 2 Operator consoles Main and auxiliary command semi automatic Plate Changer Ductrol Dampening Technotrans GAMMA 450 Combi Unit Ink Remote Control Automatic Blanket washiing devices 1 QTI automatic color registration control system 1 QTI cut control 1 Band break detection package 1 Contiweb Ecotherm 75-1020 Dryer 1 Goss Chill Rolls, 4-Rolls 1 Goss Silicone Applicator with Technotrans Mixer 1 Folder superstructure with: 4 angle bars 1 slitting- and perforation shaft 1 Former Fold 1 Goss JF-44 combination folder with folding DELTA & Double parallel Fold 1 Set of Conveyors 1 Low pressure air blower 1 Nela plate bender & Punch 1 Stacker 1 Ink pumps 1 Electrical Cabinets Production: 4 pp A/4 8 pp A/4 12 pp A/4 16 pp A/4 24 pp A/5 32 pp A/5

Oslo Norway

Norway

Mitsubishi

D 16 Max -Heat-Set Web

2006

Commercial / Heatset

1 MEGTEC Z1500 Zero Speed Splicer - Model Z1.5-4050-18 1 Infeed Unit - WPC Micro Trak 9438U Unframed Web Guide System with additional remote for one (1) 38" webs 5 Printing Units Blanket to Blanket 2 Control console Semi-automatic plate changers. BALDWIN automatic Blanket Washing devices MITSUBISHI Dampening System Refrigeeraation Units 1 MEGTEC Dual Dry III drying system for one 11900 mm 8 WPC Model 300B web break detectors 1 WPC Model Micro Trak 9910 CLC PLUS Closed Loop Color/Register 1 WPC Micro Trak #9501 Cut-off-control - one full unit, includes encoder 1 Chill Unit with 4 Chill rollers 1 WPC Micro Trak 9438F Framed Web Guide System with additional remote control 1 Baldwin Model 1145 38" Web Catcher System. 1 Mitsubishi Diamond 16 Pinless Combination Folder Single Chopper with Digest, Capable of producing Tabloid, Magazine and Digest folded products. 1 AWS Model LPA-1200 Folder Air Cooler. 10 AWS Inkqualizer Model INK-38 Ink Levelers. with operator panel, microprocessor station, interconnecting cables), air control system, 1 AWS Anti-sweat Plus I unit with integrated CRP-3H’s. 1 D & R Remote Controlled Four Head Needle Line Gluer/Moistener 1 VITS Sheeter

Oslo Norway

Norway

Mitsubishi

BT2-800SD

2005

Commercial / Heatset

1 MEGTEC Zero Speed Splicer 1 Web Guide System with additional remote for one 1 web, mounted in infeed. web break detectors 4 Prniting Units (Blanket to Blanket) single diameter Plate- and Blanket cylinder 2 control console Semi-automatic plate changers Baldwin Impact Blanket washing deice for 10 printing Units - electrical control system 1 MEGTEC Dual Dry III drying system for one 1 web Length 10000 mm 1 web catcher System 1 Closed Loop Color Register 1 Cut-Matic 5000 Cut-off-control - one full unit, 1 Web Guide System with additional remote for one 1 web, freestanding at chill stand 1 Chill Unit with 3 Chill rollers 1 Silicone Applicator 1 Glueing and Moistering Unit 1 MITSUBISHI Folder super structure with Former fold - Angle bars - slitting- and perforation shaft 1 Mitsubishi Diamond 16 Pinless Combination Folder Single Chopper with Digest, capable of producing Tabloid, Magazine and Digest folded products 2 deliveries 1 GUNCE Finishing Line 1 ROBOT

Oslo Norway

Norway

Manroland

ROTOMAN

2004

Commercial / Heatset

Cut-off: 620 mm Web-Width max.: 965 mm Web-Width min.: 450 mm Roll Diameter: 1271 mm Production Speed: 50.000 rev./h Wed-direction: left to right Configuration: 1 MEGTEC Splicer DLP2-50 autom. splicer - 1 MAN Infeed Unit with E&L web guide control 4 MAN Double Printing Units Press-Manager Terminal with printer HYDROMIX alcohol film Dampening TECHNOTRANS Refrige ration delta.d 200W BALDWIN/IMPACT Blanket Washing Device PPL Semi automatic plate changer Refrigertion Unit for Dampening TECHNOTRANS Ink Supply and leveling 1 MAN Web catcher 1 MEGTEC Dual Dry TNV 91 1 MAN Chill Unit with four Chill rollers 1 WEKO Silicon applicator WFG 1.4 1 PLANATOL COMBIJET 8 MOD Gluing 1 MAN-PECOM Video-System cut-off register 1 MAN PECOM Video- System color register 1 E&L Web guide Control 1 MAN Folder Superstructur 1 Former Fold - 3 Angle bars - Perforation and Slitting shafts 1 MAN Folder PFI-16-1 System 2:3:3:3 DELTA and Double parallel fold ( folded Size A/3 - A/4 - A/5 - long/Din 6 1 BECKER SV 2.400 Blast Air Generator with air cooler

Oslo Norway

Norway

Omet

Flexy 330

2008

Flexo

Max Web Width: 330mm Thickness: from 50 to 350 micron Servo driver Configuration: Unwinder 3 x Corona Treatment 8 x Flexo Printing Units 8 x GEW UV dryers Delam/Relam Cold foil Cooled drums (with chiller) 2 x die cutting units Web video register control Silicone cut. Blade cutting Double Rewinder Accessories: 8 x cylinders Z96,Z144,Z74,Z82 1x magnetic cylinders Z96,Z144 8 x anilox

Terni Italy

Italy

Sanjo

PO3-350 - 5c Fp H Hemb F

2002

Labels and Forms

Unwinder unit Elguider system n. 5 offset waterless printing units n. 5 UV-VT1 standard system device n. 1 Flexo varnish unit n. 1 UV-VT1 special system devices n. 2 Hot foil or embossing unitz n. 1 Flat die cutting unit LD35 Rewinder unit

Terni Italy

Italy

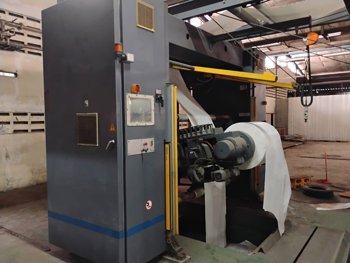

KBA

Pastoline 50 / 1000

2012

Web Components

age 2012 reelstand - web feder newspaper- and commercial presses computer control with monitor web width 400 - 1.000 mm Patras M manual web supply Delivery time: immediately from stock Ref: KB210052A Please ask for price. We ship and install worldwide!

Vogtei Germany

Germany

Find the Right Equipment

Kindly add details of the equipment you seek; and you shall find. Our community of manufacturers, sellers, and professionals will procure it for you.

Click Here

The World of Print at your Fingertips

The Machine Dalal Mobile Apps

Download our Machine Dalal App Regular updates from our magazine with illustrations, innovations , commodities, history, media, art and a whole lot more from the magnificent world of Print.

Get the App

Login

Login