Popular Brands Or view all

Post Press Machinery for Sale | Preowned & Preloved

Horizon

Collator VAC-1000m

2016

Collating and inserting lines

We are pleased to offer: Used Horizon 1000m Tower Collating Module Year 2016 Specification The Horizon 1000M Tower is a modular collating (gathering) tower designed to expand the capacity of a Horizon VAC-1000 collating system. It is intended as an expansion module that integrates seamlessly with other Horizon towers to build a multi-tower collating line for high-volume sheet gathering prior to finishing. Unlike the primary VAC-1000a tower, the 1000M tower does not include its own control display and is configured solely to add additional feed stations to an existing system. Its design allows print finishing operations to adapt the system to varying production volumes by increasing the total number of sheet bins available. Horizon’s rotary vacuum suction feeding system ensures reliable paper feeding and stacking across a wide range of paper weights and formats, supporting continuous production flow when combined with other towers in a VAC-1000 line. VAC-1000 Model: VAC-1000m Serial Number: 024301 Number of Bins: 10 bins each bin Sheet Feeding System: Suction Rotor System Sheet Size (Width × Length): Max. 350 × 500 mm / Min. 148* × 148 mm *Machine can collate the sheet of 120 mm or 4.73” width when option guide is attached. Sheet Weight Range: Art / Coated Paper: 73.3 to 207 gsm, Normal Paper: 52.3 to 207 gsm, 8-page fold signature: up to 104.7 gsm Bin Stack Height: Max. Stack Height: 55 mm / Max. Stack Weight: 11 kg or 24.3 lb each bin Sheet Overlap Front delivery: 4 Steps Maximum, Large, Middle and Small / Rear delivery: 4 Steps Maximum, Large, Middle and Small Production Speed 10 bins: Max. 9,900 sets per hour (A5LEF, Straight Receiving) Max. 8,900 sets per hour (A4LEF, Straight Receiving) *Production speed is limited by the type of finisher or sheet weight. Receiving Tray: Swing Type SW-20 /Stack Type ST-60, ST-40 / Jogger Type PJ-77, PJ-77R Voltage / Frequency: Single Phase 208 / 220 V, 50 or 60 Hz, Single Phase 230 to 240 V, 50 or 60 Hz Machine Dimensions: 930 (W) × 652 (D)* × 1,962 (H) mm *1 Blower box excluded: 693 mm or 27.3” (D) when including the projection Good working order Available immediately

Hampshire United Kingdom

United Kingdom1983

Bobst

SP 102 E

1983

Die cutting

autoplatine, die cutting machine. Year 1983 max 102x720 min. 40x35 speed 7.500 s/h pressure 250 t. Stripping device

Provincia di Siena Italy

Italy

Zhejiang Feiyun

FG-800C4/6

2019

Folder Gluer Machines

folding gluing machine year 2019 Size 800 mm Straight line Crash lock bottom 4/6 corners device Gluing device Delivery belt

Provincia di Siena Italy

Italy

Yawa

1050

2013

Die cutting

We are pleased to offer: Yawa 1050 TYM / TDS 750 × 1050 Automatic Die Cutter with Foiling Year 2016 Specification The 2016 Yawa 1050 TYM / TDS 1050 is a heavy-duty automatic flatbed die-cutting and hot foil stamping machine, designed for high-volume commercial print finishing and packaging production. This model combines powerful die-cutting performance with integrated hot foil stamping in a single pass, making it ideal for manufacturers requiring precision cutting together with premium decorative finishes. Equipped with a 300-tonne pressure capacity, three foil pull systems, and 12 independently controlled heating zones, the machine delivers consistent foil transfer and accurate die cutting across medium and large formats. The inclusion of non-stop feeder and non-stop delivery systems ensures continuous production, reducing downtime during pallet changes and increasing overall productivity. This configuration is particularly suitable for folding carton production, luxury packaging, and high-end printed materials. Maximum sheet size: 750 × 1050 mm Minimum sheet size: approx. 360 × 400 mm (depending on application) Maximum die-cutting area: approx. 1040 × 730 mm Suitable for paper, solid board and corrugated board (up to approx. 4 mm thickness, depending on material) Maximum mechanical speed: up to approx. 7,500 sheets per hour Foil stamping speed: up to approx. 6,500 sheets per hour (depending on job complexity) Maximum cutting pressure: 300 tonnes Three longitudinal foil pull systems Programmable foil advance control 12 heating zones for precise temperature distribution Compatible with metallic, pigment and holographic foils Non-stop feeder for continuous sheet loading Non-stop delivery for uninterrupted stacking High-capacity pile loading and delivery systems Precision gripper bar transport for stable sheet control ????Heavy-duty steel frame construction Flatbed die-cutting system with closed chase PLC control with touchscreen interface Automatic lubrication system (where fitted) Safety guarding compliant with industrial standards ????Typical Applications: Folding carton die cutting Luxury packaging with hot foil stamping Premium printed materials (invitations, covers, presentation folders) Decorative metallic and holographic foil finishing Combined die cutting and foil stamping production in a single pass Good working order Available immediately

Hampshire United Kingdom

United Kingdom

Duplo

System 3500

2013

Booklet machines

We are pleased to offer: Used Duplo System 3500 Dynamic Booklet Maker Year 2013 Specification The Duplo System 3500 Dynamic Booklet Maker is an automated solution for producing booklets, brochures, and bound printed materials, ideal for digital printers and medium-volume production. It combines several finishing processes in a single line: Automated sheet feeding from digital printer output. Staple binding and folding of booklets. Front trimming for professional edge finishing. The system is composed of multiple integrated modules: DSF‑2200 Sheet Feeder – Feeds sheets or signatures from printers, collated or uncollated. DBM‑3500 Booklet Maker – Main machine that staples, folds, and assembles the booklets. DBM‑3500 Trimmer – Integrated front trimmer for uniform, professional finishing. This combination offers a semi-automatic to fully automatic workflow, streamlining the finishing process and reducing manual intervention. Production speed: Up to 3,000 booklets per hour (typical for A5 size). Feeding capacity (DSF‑2200): Upper tray: ~65 mm Lower tray: ~200 mm Feeding speed: up to ~200 sheets per minute Paper Sizes and Weights Paper size range: approximately 105 × 148 mm up to 320 × 460 mm depending on configuration. Paper Capacity: 20 sheets [Cover x 1(300gsm) 19 sheets (81.4 gsm) equivalent Stitch heads: 2 Compatible paper weight: approximately 52 – 300 gsm. Maximum sheets per booklet: about 20 sheets plus cover in standard configuration. Dimensions and Power: Overall dimensions (with DSF‑2200 and trimmer): ~4.48 m long × 0.75 m wide × 1.03 m high Combined weight: ~395 kg Power supply: 230 V, 50 Hz Good working order Available immediately

Hampshire United Kingdom

United Kingdom

Viking

VK 1330 Hand-Fed Platen Die-Cutter

1998

Die cutting

We are pleased to offer: Used Viking VK1330 Hand-Fed Platen Year 1998 Specification The Viking VK1130 is a hand-fed platen press / die-cutter built for heavy-duty finishing work in print, packaging and boxmaking environments. This robust industrial machine is designed to press, cut or die-cut sheet materials using a heavy platen mechanism operated manually or in semi-automatic modes. It is valued for precision, durability and flexibility when processing thicker substrates that require firm, controlled press pressure. The VK1130 is typically equipped with a solid frame and platen design that ensures stable operation and accurate cutting or pressing even on complex or heavy materials. The hand-fed operation makes it suitable for both short runs and moderate production volumes, where ease of setup and reliability are priorities. Max Sheet Size (Length × Width):1330 × 960 mm Operating Modes: Single, continuous, dwell Max Speed: up to 1,500 sheets/hour Power Supply: 3-phase, ~380 V (typical for UK/Europe) Safety Features: Goal-post guards, safety edges, fail-safe brakes Weight: approx. 6,200 kg Good working order Available immediately

Hampshire United Kingdom

United KingdomPO260008A

Polar

115 ED

2000

Guillotines

width 137 cm age 2000 AUTOTRIM computer control with monitor colour screen air table metallized 2 side tables jogger RA-4 with press roller Transomat TR 130 EL-4 handling from right to the left Ref: PO260008A Please ask for price. Worldwide delivery & installation

Stuttgart Germany

Germany

Muller Martini

TIGRA

2004

Perfect binder lines

2004 Used Muller Martini model Tigra perfect binder. 9 Clamps perfect binder with Milling & Notching unit, Two bag waste collector, Spine EVA glue unit with a Premelter & Side glue unit, Pile Cover feeder, Pressing station, Lay down. 16x Gathering unit with Criss cross delivery unit for rejection and Gathering & Hand feed unit. Conveyors to 3 knife Esprit trimmer. Machine worked one shift and was bought new by the customer. 460V, 3 Ph, 50/60Hz.

Regional Municipality of Niagara Canada

Canada

DAI`S

1370

2016

Paper/Sheet Cutting Machines

The DAI'S Model 1370 is a precision paper and sheet cutting machine designed for industrial applications, offering reliable performance for cutting various paper materials with accuracy. Ideal for print shops, packaging manufacturers, and paper processing facilities, this machine ensures clean, consistent cuts while enhancing productivity. Manufactured in 2016, the Model 1370 combines durability with efficient operation, making it a practical choice for high-volume cutting tasks.

Guang Zhou Shi China

China

KONGQUE

1500

2013

Die cutting

The KONGQUE 1500 is a specialized die cutting machine designed for precision paper converting applications. Operating in the die cutting category, this 2013 model delivers accurate cutting, creasing, and embossing for various paper materials. Known for its reliability and efficiency, the machine is ideal for producing packaging, labels, and decorative paper products. Its robust construction ensures consistent performance in high-volume production environments, making it a valuable asset for printing and packaging industries.

Guang Zhou Shi China

China

HONGSEN

920

2020

Laminating machines

The HONGSEN 920 is a high-performance laminating machine designed for industrial and commercial applications. As part of the Laminating machines category, this model excels in providing durable, protective laminations for documents, photographs, and various printed materials. Known for its reliability and efficiency, the HONGSEN 920 ensures smooth operation with minimal maintenance, making it ideal for print shops, offices, and production environments. Its robust construction and precise engineering deliver consistent results, enhancing the longevity and appearance of laminated items.

Guang Zhou Shi China

China

RUIAN

1300

2001

Die cutting

The RUIAN 1300 die cutting machine is a specialized industrial equipment designed for precise cutting, creasing, and shaping of paper and cardboard materials. Operating within the die cutting category, this machine is ideal for high-volume production environments requiring consistent accuracy and efficiency. Key features include robust construction, reliable performance, and compatibility with a wide range of paper weights. The RUIAN 1300 is particularly suited for applications in packaging, printing, and manufacturing industries where precision cutting is essential for product quality and workflow optimization.

Guang Zhou Shi China

China

Zhejiang Feiyun

TYMK-750

2017

Die cutting

The Zhejiang Feiyun TYMK-750 is a specialized die cutting machine designed for precision paper and material processing in industrial settings. Ideal for high-volume production, this 2017 model delivers accurate cutting, creasing, and shaping of various substrates, particularly paper starting from 70 g/m². Known for its reliability and efficiency, the TYMK-750 is well-suited for applications in packaging, printing, and manufacturing sectors where consistent quality and productivity are essential.

Guang Zhou Shi China

China

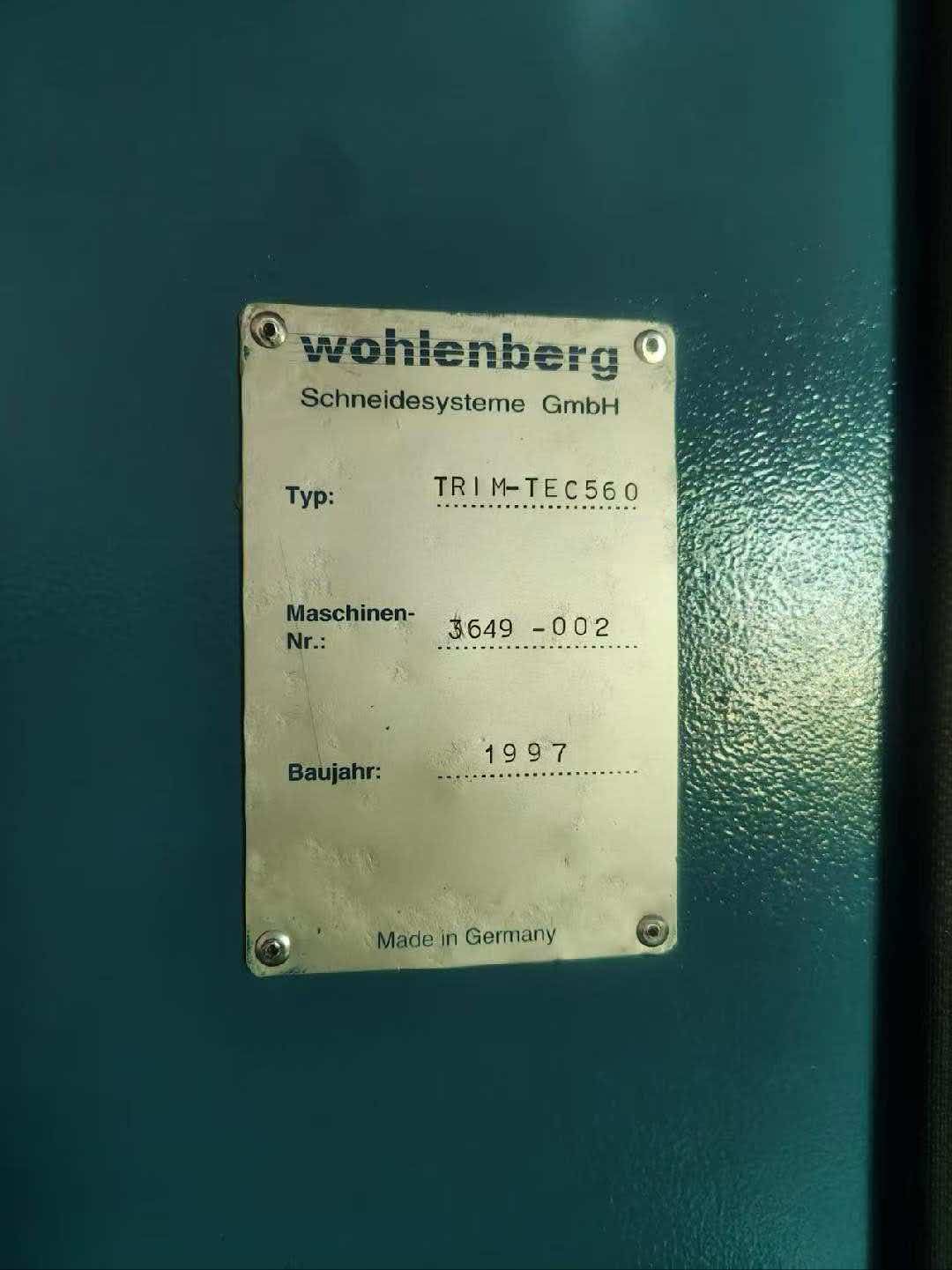

Wohlenberg

TRIM-TEC560

1997

Three Knife Trimmer

The Wohlenberg TRIM-TEC560 is a robust three-knife trimmer designed for precision cutting in industrial print finishing and bookbinding applications. As part of the Three Knife Trimmer category, this machine ensures high accuracy and efficiency in trimming stacks of paper, cardboard, or other materials to exact dimensions. Known for its durability and reliability, the TRIM-TEC560 is ideal for commercial printers, binderies, and packaging manufacturers requiring consistent, high-quality trimming. Its sturdy construction and advanced cutting mechanism make it suitable for handling large volumes while maintaining precision.

Guang Zhou Shi China

China

Wohlenberg

F50

1991

Three Knife Trimmer

The Wohlenberg F50 Three Knife Trimmer is a precision industrial machine designed for high-volume cutting and trimming of paper, books, and other printed materials. As a three-knife trimmer, it ensures clean, accurate, and efficient trimming with minimal waste, making it ideal for bookbinding, commercial printing, and finishing operations. Known for its durability and reliability, this model delivers consistent performance in demanding production environments, enhancing workflow efficiency and product quality. Built by Wohlenberg, a trusted manufacturer with decades of expertise, the F50 is well-suited for publishers, print shops, and binderies requiring precise and repeatable trimming results.

Guang Zhou Shi China

China

AOER

AEM-800

2018

Die cutting

The AOER AEM-800 is a precision die cutting machine designed for high-efficiency industrial applications. As part of the die cutting category, this model excels in accurately cutting and shaping materials with consistent results. Key features include robust construction, reliable performance, and compatibility with a wide range of paper weights, making it ideal for packaging, labeling, and specialty paper production. The AEM-800 is well-suited for manufacturers seeking durability and precision in their cutting processes.

Guang Zhou Shi China

China

DONGRUI

930

2012

Die cutting

The DONGRUI 930 is a precision die cutting machine designed for high-volume industrial applications, specializing in accurate and efficient cutting of paper materials. Ideal for packaging, label production, and print finishing, this 2012 model delivers reliable performance with its robust construction and advanced features. The machine supports paper weights starting from 70 g/m², making it versatile for various substrates while ensuring clean, consistent cuts for optimal productivity.

Guang Zhou Shi China

China

DONGRUI

TYMB 1100

2016

Die cutting

The DONGRUI TYMB 1100 is a precision die cutting machine designed for high-volume industrial applications, specializing in accurate and efficient cutting of paper and cardboard materials. Operating within the die cutting category, this model excels in producing clean, consistent cuts for packaging, labels, and decorative products. Key features include robust construction, reliable performance, and compatibility with a wide range of paper weights. Ideal for print finishing, packaging production, and specialty converting, the TYMB 1100 enhances productivity while maintaining exceptional quality standards.

Guang Zhou Shi China

China

SHENWEIDA

QZK1150A

Paper/Sheet Cutting Machines

The SHENWEIDA QZK1150A is a precision paper and sheet cutting machine designed for industrial applications requiring accurate and efficient cutting of various paper materials. As part of the Paper/Sheet Cutting Machines category, this model delivers reliable performance for high-volume production environments. Known for its robust construction and user-friendly operation, the QZK1150A ensures clean, precise cuts while maintaining productivity. It is ideal for use in printing houses, packaging facilities, and paper converting industries where consistent sheet sizing is critical.

Guang Zhou Shi China

China

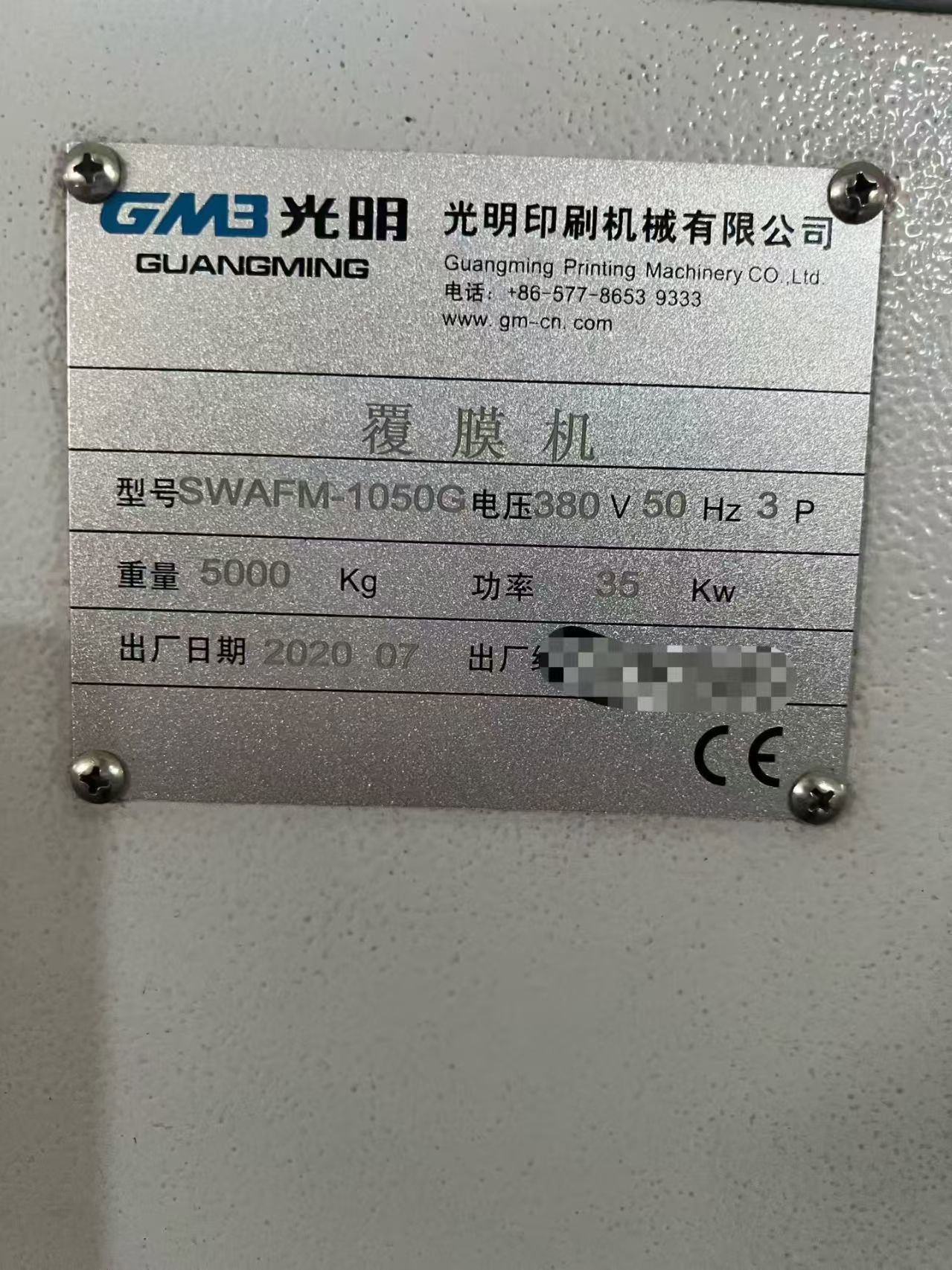

Guangming

SWAFM-1050G

2020

Laminating machines

The Guangming SWAFM-1050G is a high-performance laminating machine designed for industrial applications, offering precision and efficiency in protective film lamination. Ideal for enhancing document durability, packaging, and graphic arts, this model ensures smooth operation with reliable output quality. Manufactured in 2020, it combines robust construction with user-friendly features, making it suitable for businesses seeking consistent laminating performance.

Guang Zhou Shi China

China

SHENWEIDA

1300

2009

Paper/Sheet Cutting Machines

The SHENWEIDA 1300 is a precision paper and sheet cutting machine designed for industrial applications, offering reliable performance for cutting various paper materials with accuracy. Ideal for print shops, packaging manufacturers, and paper processing facilities, this model ensures clean cuts, efficiency, and durability. Built in 2009, it combines robust construction with user-friendly operation, making it a practical choice for high-volume cutting tasks.

Guang Zhou Shi China

China

AOER

AEMQ1080

2015

Die cutting

The AOER AEMQ1080 is a precision die cutting machine designed for industrial paper processing applications. Operating within the die cutting category, this model excels in high-volume production environments, delivering accurate cuts and consistent results. Key features include robust construction, reliable performance, and compatibility with a wide range of paper weights. Ideal for packaging, labeling, and specialty paper products, the AEMQ1080 enhances productivity while maintaining quality standards. Its 2015 manufacturing year ensures a balance of proven technology and operational efficiency.

Guang Zhou Shi China

China

Polar

137

2012

Paper/Sheet Cutting Machines

The Polar 137 is a precision paper and sheet cutting machine designed for industrial printing and finishing operations. As part of the Paper/Sheet Cutting Machines category, this model excels in delivering accurate, high-volume cutting for various paper stocks and materials. Known for its reliability and efficiency, the Polar 137 is ideal for commercial print shops, packaging manufacturers, and bindery operations, ensuring clean cuts and consistent results for applications such as bookbinding, brochure production, and packaging fabrication.

Guang Zhou Shi China

China

Horizon

BQ-140

2000

Perfect Binder and Gatherer

We are pleased to offer: Used Horizon BQ-140 (1 Clamp Binder) Year 2000 Specification The Horizon BQ-140 is a compact and reliable perfect binding machine designed for professional bookbinding applications. It is ideal for short to medium production runs, offering consistent binding quality with simple operation. The machine features automatic spine preparation and hot-melt glue application, combined with manual cover feeding, making it a practical and cost-effective solution for commercial print shops and in-house finishing departments. Binding method: Hot-melt perfect binding Spine preparation: Automatic notching Cover feeding: Manual Number of clamps: 1 Maximum speed: Up to approx. 250 books per hour (operator dependent) Maximum binding thickness: Up to approx. 30 mm Maximum book size: Approx. 300 × 400 mm Minimum book size: Approx. 105 × 148 mm Power supply: 110–120 V (depending on configuration) Power consumption: Approx. 300–950 W Dimensions & Weight (approx.): Width: 1,450 mm/ Depth: 420 mm/ Height: 1,040–1,130 mm Weight: Approx. 110–200 kg Good working order Available immediately

Hampshire United Kingdom

United Kingdom

Muller Martini

PRESTO

1997

Saddle Stitcher

We are pleased to offer: Muller Martini Presto Year 1997 Specification The Müller Martini Presto is a high-performance saddle stitching system designed for efficient and reliable production of brochures, magazines, catalogues and other stitched products. Renowned for its Swiss engineering, the Presto offers excellent precision, durability and consistent output, making it a proven solution for commercial print finishing environments. This machine is suitable for short to medium production runs, combining high operating speed with easy set-up and stable operation. Thanks to its modular design and PLC control system, it delivers flexibility, accuracy and dependable performance over long production cycles. The unit offered is in good working condition, with approximately 6,000 production hours, and testing is possible. Type: Saddle stitching system Maximum speed: Up to 9,000 cycles per hour (depending on configuration) Maximum sheet size: 6 × 1,551 mm Maximum finished product thickness: Up to approx. 10 mm (depending on setup) Feeders: Müller Martini 1522 Cover feeder: Included (depending on configuration) Stitching heads: 2 stitching heads Stitching type: Wire stitching on the saddle Trimmer: 3-knife trimmer Trimming: Head, face and foot trim Control system: PLC controls Delivery: Shingle belt delivery system Good working order Available immediately

Hampshire United Kingdom

United Kingdom

Yawa

750

2009

Die cutting

The Yawa 750 is a precision die cutting machine designed for high-volume industrial applications, specializing in accurate and efficient cutting of paper materials. Operating in the die cutting category, this model excels in producing clean, consistent cuts for packaging, labels, and decorative products. Key features include robust construction, reliable performance, and compatibility with paper weights starting from 70 g/m². Manufactured in 2009, the Yawa 750 offers cost-effective solutions for businesses requiring precise cutting capabilities with minimal waste, making it ideal for print finishing, packaging production, and specialty paper applications.

Guangzhou China

China

AOER

AEM-1650VQ

Die cutting

The AOER AEM-1650VQ is a specialized die cutting machine designed for precision cutting applications in industrial settings. This equipment is ideal for processing paper materials, offering reliable performance for tasks such as packaging production, label manufacturing, and other converting processes. With its robust construction and efficient operation, the AEM-1650VQ ensures high-quality results while maintaining productivity. Key features include compatibility with a wide range of paper weights, making it versatile for various applications.

Guangzhou China

China

DONGRUI

2020

2020

Die cutting

The DONGRUI 2020 is a precision die cutting machine designed for high-efficiency paper processing in industrial settings. Ideal for cutting, creasing, and shaping paper materials, this model excels in producing consistent, high-quality results for packaging, labels, and decorative applications. With a focus on reliability and versatility, the 2020 model supports paper weights from 70 g/m², ensuring adaptability across various production needs. Its robust construction and advanced features make it a valuable asset for print finishing, carton manufacturing, and specialty paper processing.

Guangzhou China

ChinaAM250235A

Ambaflex

Drying Tower

2013

Perfect binder lines

age 2013 drying tower Ambaflex belt width 40 cm belt length 20 m infeed height approx. 50 cm exit height approx. 120 cm direction 90° left speed up to 13 m / min Delivery time: immediately Ref: AM250235A Please ask for price. Worldwide delivery & installation

Stuttgart Germany

Germany

TYML

750A

2013

Die cutting

The TYML 750A is a precision die cutting machine designed for high-volume industrial applications, specializing in accurate and efficient cutting of paper materials. Ideal for packaging, printing, and manufacturing sectors, this 2013 model delivers reliable performance with its robust construction and advanced features. The machine supports paper weights starting from 70 g/m², ensuring versatility for various substrates while maintaining consistent quality and productivity.

Guangzhou China

China

Yawa

920

2006

Die cutting

The Yawa 920 is a precision die cutting machine designed for high-volume production environments, specializing in accurate and efficient cutting of paper and cardboard materials. Ideal for packaging, label production, and commercial printing applications, this 2006 model combines robust construction with reliable performance. The machine is engineered to handle paper weights starting from 70 g/m², ensuring versatility for various substrates while maintaining consistent quality and operational efficiency.

Guangzhou China

China

WANNENGBAO

FM50

Three Knife Trimmer

The WANNENGBAO FM50 Three Knife Trimmer is a precision industrial machine designed for high-volume cutting and trimming operations. Ideal for print finishing, packaging, and commercial binderies, this robust trimmer ensures clean, accurate cuts with minimal waste. Its three-knife configuration enhances efficiency, making it suitable for processing books, brochures, catalogs, and other printed materials with consistent quality and reliability.

Guangzhou China

China

Polar

137

2007

Paper/Sheet Cutting Machines

The Polar 137 is a precision paper and sheet cutting machine designed for industrial applications, offering reliable performance for cutting various paper sizes and materials. Manufactured in 2007, this model is ideal for print shops, packaging facilities, and commercial operations requiring accurate and efficient cutting solutions. Known for its durability and ease of use, the Polar 137 ensures clean cuts, consistent results, and enhanced productivity in high-volume environments.

Guangzhou China

China

Duplo

DPB 500

2007

Perfect Binder and Gatherer

We are pleased to offer: Used Duplo DPB-500 EVA Binder Year 2007 Specification Counter: 0015627 The Duplo DPB-500 EVA Binder is a fully automatic single-clamp perfect binding machine designed for efficient and high-quality softcover book production. Using EVA hot-melt adhesive, it delivers strong, consistent binding results and is particularly well suited to short-to-medium production runs, digital print environments and print-on-demand applications. This model combines automated set-up, effective spine preparation and precise glue application, ensuring professional binding quality with minimal operator intervention. The DPB-500 is widely used by commercial printers and book manufacturers for producing paperbacks, manuals, catalogues and instructional materials. Maximum Production Speed: Up to 525 books per hour Book Thickness: Min. 1 mm – Max. 51 mm (excluding cover) Book Size (Spine × Fore-Edge): Max. 360 mm × 320 mm / Min. 120 mm × 120 mm Cover Size: Max. 360 mm × 696 mm / Min. 120 mm × 250 mm Cover Weight: 80 – 302 gsm Glue System: Hot-melt adhesive with large glue tank, two heated drums and side-glue wheels, plus notching and spine preparation up to 4 mm depth Book Clamps: 1 Control System: Touch-screen control panel Electrical Requirements: Three-phase Y380-Y415 V or similar 50/60 Hz (Europe) Dimensions (approx.): 2,790 mm (W) × 928 mm (D) × 1,343 mm (H) Machine Weight: Approx. 695 kg Good working order Available immediately

Ringwood United Kingdom

United Kingdom

Tecnau

Libra 800

2016

Book Production

We are pleased to offer: Used TECHNAU LIBRA 800 Book Production Line Year 2016 Specification Tecnau Libra 800 line, effectively doubling the system’s on-demand book manufacturing capacity. Designed for high-variability, short-run and one-copy-per-job production, the line enables seamless finishing of unique books with zero changeover time. The Tecnau Libra 800 is a fully automated book finishing solution capable of processing each book with different formats, thicknesses, and cover styles. It integrates unwinding, book-block assembly, binding, and three-knife trimming into a single continuous workflow. With two Libra 800 units working in parallel, the system significantly increases throughput while maintaining consistent quality and precise dimensional control. Technical Specifications – Tecnau Libra 800 (per line) Productivity Up to 800 books per hour (per Libra 800 line) Combined output with two lines: up to 1,600 books per hour Input / Feeding: Continuous web input or pre-assembled book blocks Supports variable format book-of-one workflow Finished Book Size: Width: Min. 130 (5.1”)/ Max. 220 mm (8.66”), max. 297 mm (11.69”) (at reduced speed) Spine height: Min. 130 mm (5.1”), max. 305 mm (12”) Book Thickness: 2 – 60 mm (0.079-2.36”) Input from roll: Web width: Max. 540 mm Printing mode: 1 up, 2up and 3 up depending on configuration selected Paper weight: 60-120 gsm Soft Cover: Width: Min.280 mm (11”) / Max. 520 mm (20.5”), max. 680 mm (26.77”) (at reduced speed) Height(spine): Min. 140 mm (5.5”) – Max. 320 mm (12.6”) Weight: 250 gsm coated & laminated End Sheets: Width: Min. 150 mm (5.9”)-Max. 230 mm (9.06”), max. 310 mm (12.2”) (at reduced speed) Height (spine): Min. 190 mm (7.5”)- Max. 305 mm (12”) False Cover: Width: Min. 300 mm (11.8”) - Max. 620 mm (24.4”) Height: Min. 190 mm (7.5”) – Max. 305 mm (12”) Binder (Books Block): Width Min. 140 mm (5.5”)- Max. 230 mm (9.06”), max. 310 mm (12.2) (at reduced speed) Height (spine): Min. 140 (5.5”) - Max. 315 mm (12.4”) Thickness: 2-60 mm (0.079-2.36”) Trimmer: Width: Min. 130 mm (5.1”)- Max. 320 mm (12.6”) Height (spine): Min. 130 mm (5.1”) - Max. 360 mm (14.2”) Thickness: 2-60 mm (0.079-2.36”) Binding Technology: EVA glue (or hotmelt configuration) Good working order Available immediately

Ringwood United Kingdom

United Kingdom

AOER

AEM-1080B

2020

Die cutting

The AOER AEM-1080B is a precision die cutting machine designed for high-efficiency paper and material processing in industrial settings. As part of the die cutting category, this model excels in producing accurate cuts, creases, and perforations for packaging, labels, and decorative applications. Key features include robust construction, reliable performance, and compatibility with a wide range of paper weights. Ideal for print finishing, packaging production, and specialty paper applications, the AEM-1080B ensures consistent quality and operational efficiency, making it a valuable asset for manufacturers seeking precision and durability.

Guangzhou China

China

Find the Right Equipment

Kindly add details of the equipment you seek; and you shall find. Our community of manufacturers, sellers, and professionals will procure it for you.

Click Here

The World of Print at your Fingertips

The Machine Dalal Mobile Apps

Download our Machine Dalal App Regular updates from our magazine with illustrations, innovations , commodities, history, media, art and a whole lot more from the magnificent world of Print.

Get the App

Login

Login