Machine Description

Unwinding.

.

Splice detection with acoustic warning signal.

.

Web edge control.

.

Web break control.

.

2x Corona infeed, behind unit 4 (Vetaphone/Softal).

.

1x Arcotec web cleaning.

.

8 printing platforms.

.

8 flexographic printing units.

.

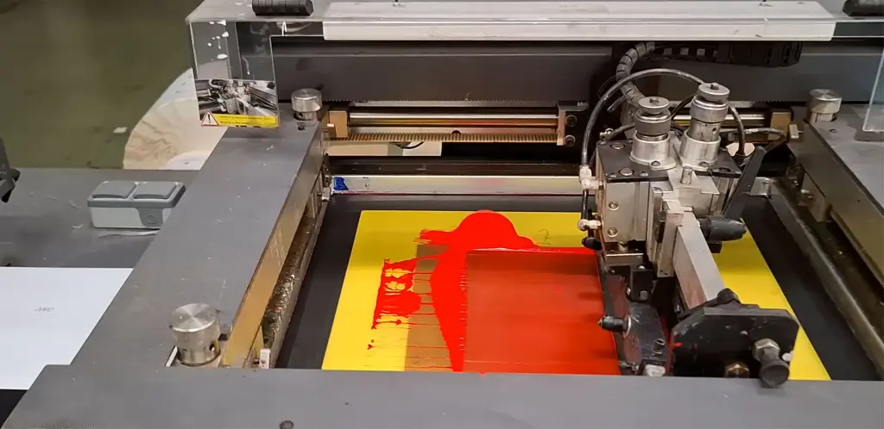

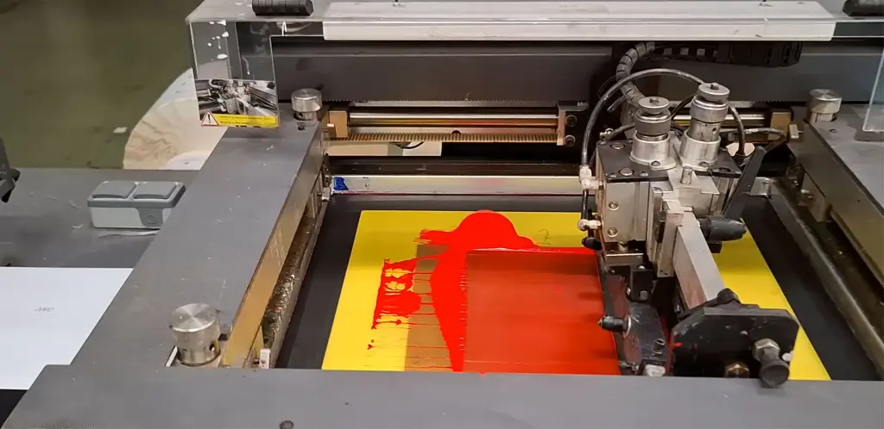

3x screen printing units, interchangeable.

.

2x rotary die-cutting units.

.

Scribing tool with cross cutter.

.

Rail system.

.

1x additional winding/unwinding unit (laminate).

.

1 x additional cold foil embossing.

.

Insertion offset station for the production of multi-layer labels (web offset device).

.

8x GEW UV dryers with cooling roller.

.

Hyfra cooling machine.

.

BST video control.

.

Automatic register control Sensotec.

.

Job data management for up to 500 jobs.

.

Format length correction in the printing and processing area - Recommended for stretchable materials.

.

Grid winder.

.

Unwinding.

.

Spreading roller and pressure arm for crease-free winding of thin foils and aluminum..

.

1x transport trolley.

.

2x transport trolley process change.

.

8 change axes for Z 72.

.

Print cylinder-.

.

Magnetic cylinder-.

.

Anilox-...

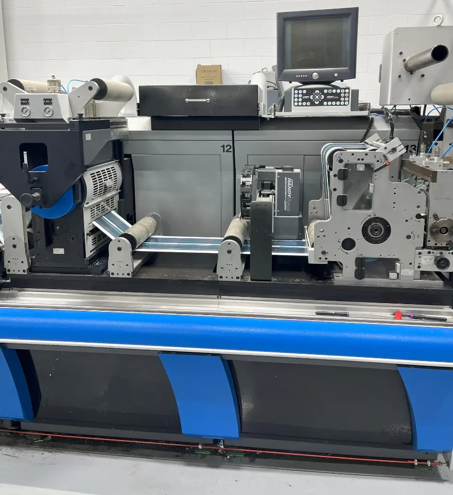

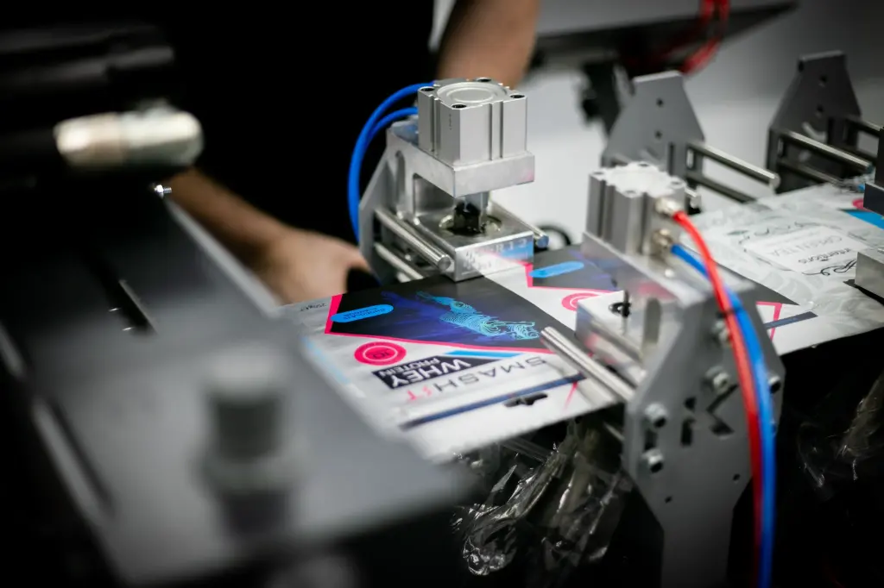

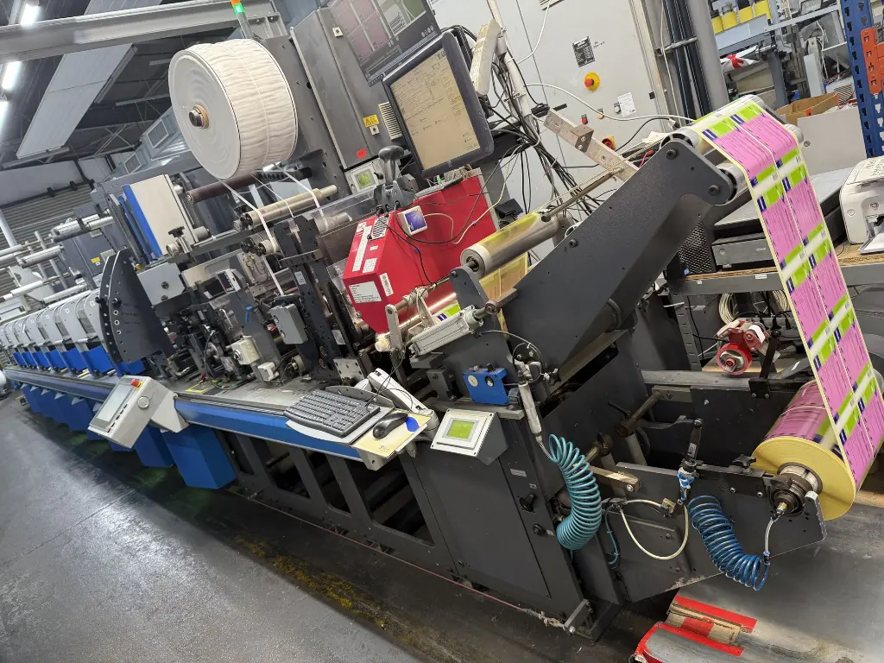

The Gallus EMS 340 is a high-performance flexographic equipment designed for precision label and packaging production. This advanced machine combines flexographic, screen printing, and rotary die-cutting capabilities, making it ideal for producing multi-layer labels, flexible packaging, and specialty applications. Key features include automated web control, UV drying systems, and interchangeable printing units, ensuring high-quality output with minimal waste. The EMS 340 is particularly suited for industries requiring versatile printing solutions, such as pharmaceutical, food and beverage, and consumer goods labeling.

Key Technical Aspects:

Printing Unit : The EMS 340 features 8 flexographic printing units and 3 interchangeable screen printing units, enabling high-resolution printing with up to 8 colors. It includes an insertion offset station for multi-layer label production and supports hybrid printing processes for enhanced versatility.

Ink System : Equipped with 8 GEW UV dryers and cooling rollers, the machine ensures rapid ink curing and temperature control for consistent print quality. The system is optimized for UV-curable inks, reducing drying times and improving production efficiency.

Plate Cylinder : The machine includes 8 change axes for Z 72 print cylinders and magnetic cylinders, allowing quick job changes and precise registration. Anilox rollers are also supported for consistent ink transfer and print uniformity.

| Model | Gallus-EMS 340 |

|---|---|

| Manufacturer | Gallus |

| Year | 2009 |

| Machine Availability | Immediately |

| Machine Condition | In Stock |

| Price | On Request |

| Location | Max-von-Eyth-Straße 23A, 27798 Hude, Germany |

Gallus - EMS 340

Send Message to Seller

MessageAvail Financing

We work with multiple financial partners to help you avail credit facility to buy your equipment. Kindly confirm your details and our representative shall contact you.

Click HereShipping & Logistics

Please provide basic information on port of origin and destination and the right person shall contact you.

Click HereHave a Query?

Got a question about this machine? Send your query to the seller and they will reply with the relevant information shortly.

Markus Media

We offer a full range of services for the purchase of Flexsodruck machines as well as advice and search of equipment to order. Dismantling, transport, delivery of spare parts, commissioning of the machines on site.

Explore Inventory trending_flatFind the Right Equipment

Kindly add details of the equipment you seek; and you shall find. Our community of manufacturers, sellers, and professionals will procure it for you.

Click Here

Recently Added Machines

The World of Print at your Fingertips

The Machine Dalal Mobile Apps

Download our Machine Dalal App Regular updates from our magazine with illustrations, innovations , commodities, history, media, art and a whole lot more from the magnificent world of Print.

Get the App

Login

Login

Recommended Machines