Machine Description

Table Size: 2120 x 3400 mm.

.

PILOT A+, PC, camera system, vacuum /w 1 pump, Cut2DPro..

.

AC servo drives and planetary gearboxes.

.

Zone Vacuum table and 1 vacuum blower (Becker).

.

Maximum speed: 1150 mm/s.

.

Maximum acceleration: 3000 mm/s2.

.

6 Zones Vacuum Bed.

.

Recognition camera system for cutting of printed materials..

.

Sophisticated CNC controller PILOT Advanced for maximum dynamics and speed. Prepared for installation of oscillating knive heads, universal tangential heads, routing spindle and more. Automatic Z Sensor, PC included..

.

Additional Noise Reduction for Vacuum Pump.

.

Spray cooling System Profi (SPRAY_PRO).

.

DIGI professional Spindle 730 W/24000 (RPM D_S_730W24T) with ramp and dust collector.

.

Professional routing and engraving spindle for DIGI.

.

3-phase spindle with ER20 tooling (up to 12 mm diameter)..

.

Ceramic bearings for professional and reliable work up to 24,000 rpm, hardened and balanced shaft..

.

Dust collector with flexible hose and steel ramp to cover complete working area. Includes one.

.

routing tool, 3 x collets (3,4,6mm). Dust collector Included.

.

Tangential Module for Universal Tool U1 (Module A) - (MODA_U1) pneumatic parking, AC servo, tangential rotation, position for insert of U1 tools.

.

Module for universal tools U1.

.

AC servo tangentially controlled panel for insertion of U1 tools. High dynamic cutting..

.

Use Kiss-cut, V-cut and other U1 cutting devices..

.

Additional Becker vacuum pump for DIGI 5,5 kW, mid-range vacuum, incl. filter, hose.

.

Additional mid-range vacuum pump, power 5,5 kW, max. flow rate 390 m3/h, maximum vacuum 315mbar rel..

.

Routing pad 2mm, size 1 x 1 m (RP20).

.

For table protection during Routing operation.

.

Kiss-cut, Knife, Knife with pressure foot, Knife thin, Knife HSS, Pen.

.

Set of 6 tools equipped with knives for U1 tooling system.

.

Kiss-cut tool with knife.

.

Knife tool with E10 knife.

.

Knife tool with pressure foot with E11 knife.

.

Knife tool thin with FN8 knife.

.

Knife tool HSS with HSS knives 50pcs.

.

Set of tools for plastics, aluminum and sandwiches.

.

Set of microcarbide tools and routing pads for flatbed cutter.

.

Router bits: A320, A330, A440, A660B, MP320, MP330, MP440, MP660B, B440, B660, D330, D440, D660.

.

Ballnose tools: BN3, BN6.

.

Engraving tools: G44506, G44515.

.

Routing pad 1mm thickness - 1x6 meters.

.

Routing pad 2mm thickness - 1x6 meters...

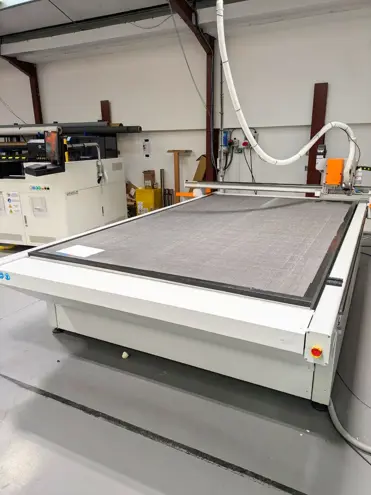

The Comagrav Digi 2034 is a high-performance digital flatbed cutting machine designed for precision cutting, routing, and engraving of various materials in industrial applications. Part of the Digital Press category, this advanced CNC system integrates cutting-edge technology, including a PILOT A+ controller, AC servo drives, and a sophisticated camera recognition system for accurate processing of printed materials. With a generous table size of 2120 x 3400 mm, high-speed dynamics (1150 mm/s max speed, 3000 mm/s² acceleration), and versatile tooling options, the Digi 2034 excels in applications such as signage production, packaging prototyping, foam cutting, and composite material processing. Its robust construction, zone vacuum table with dual vacuum pumps, and compatibility with oscillating knives, tangential heads, and routing spindles ensure reliability, efficiency, and adaptability for demanding production environments.

Key Technical Aspects:

Dimensions and Specifications : The Comagrav Digi 2034 features a large working area with a table size of 2120 x 3400 mm, supporting materials up to these dimensions. Equipped with AC servo drives and planetary gearboxes, it delivers a maximum cutting speed of 1150 mm/s and acceleration of 3000 mm/s² for high productivity. The machine includes a 6-zone vacuum bed powered by a primary vacuum blower (Becker) and an additional 5.5 kW Becker vacuum pump (390 m³/h flow rate, 315 mbar max vacuum) for secure material hold-down. Noise reduction measures are implemented for the vacuum system, and a spray cooling system (SPRAY_PRO) ensures optimal thermal management during intensive operations.

Printing Unit : While primarily a cutting system, the Digi 2034 is designed for post-print processing with an integrated recognition camera system for precise alignment and cutting of printed materials. The PILOT Advanced CNC controller enables seamless integration with pre-press workflows, supporting automated cutting paths based on print registration marks. The system is prepared for installation of various tool heads, including oscillating knives, universal tangential heads, and routing spindles, making it adaptable for finishing printed substrates with high accuracy.

| Model | Comagrav-Digi 2034 |

|---|---|

| Manufacturer | Comagrav |

| Year | 2022 |

| Machine Availability | Immediately |

| Machine Condition | In Stock |

| Price | On Request |

| Location | United Kingdom |

Comagrav - Digi 2034

Send Message to Seller

MessageAvail Financing

We work with multiple financial partners to help you avail credit facility to buy your equipment. Kindly confirm your details and our representative shall contact you.

Click HereShipping & Logistics

Please provide basic information on port of origin and destination and the right person shall contact you.

Click HereHave a Query?

Got a question about this machine? Send your query to the seller and they will reply with the relevant information shortly.

Allforprintmarket.

Allforprintmarket.com is your trusted partner for used printing & packaging machinery. With expertise in buying and selling, we’ve completed trades in 40+ countries, focusing on client needs, professionalism, and detail from first contact to final transaction.

Explore Inventory trending_flatFind the Right Equipment

Kindly add details of the equipment you seek; and you shall find. Our community of manufacturers, sellers, and professionals will procure it for you.

Click Here

Recently Added Machines

The World of Print at your Fingertips

The Machine Dalal Mobile Apps

Download our Machine Dalal App Regular updates from our magazine with illustrations, innovations , commodities, history, media, art and a whole lot more from the magnificent world of Print.

Get the App

Login

Login

Recommended Machines