Popular Brands Or view all

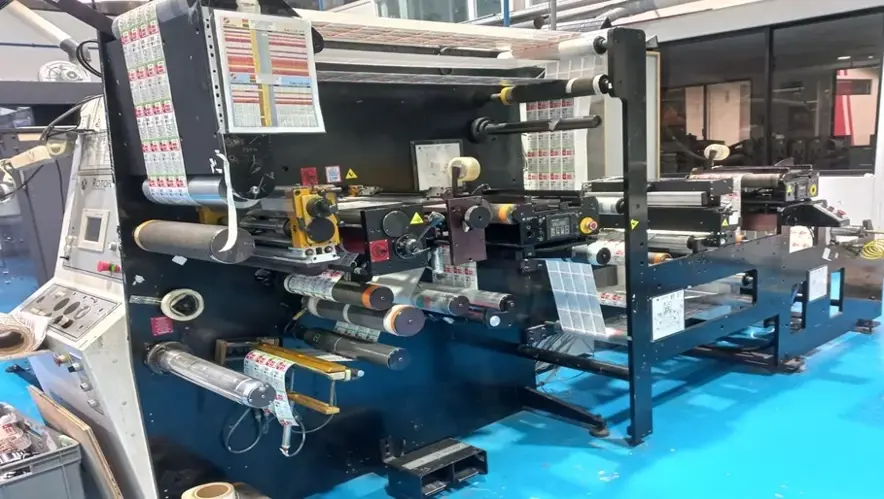

Flexographic equipment Machinery for Sale | Preowned & Preloved

Omet

Flexy S 330

2008

Flexographic equipment

Label Flexo printing machine Year 2008 Max Web Width: 330mm Thickness: from 50 to 350 micron Servo driver Configuration: Unwinder 3 x Corona Treatment 8 x Flexo Printing Units 8 x GEW UV dryers Delam/Relam Cold foil Cooled drums (with chiller) 2 x die cutting units Web video register control Silicone cut. Blade cutting Double Rewinder Accessories: 8 x cylinders Z96,Z144,Z74,Z82 1x magnetic cylinders Z96,Z144 8 x anilox

Provincia di Siena Italy

Italy

CODIMAG

Viva 340

2009

Label Printing

Printing width: 330 mm Web width max.: 340 mm Web width min.: 120 mm Printing length max.: 305 mm Printing length min.: 50 mm Speed max.: 12.000 Specification: 1 Unwind Unit - 1000 mm diameter 4 water less Offset printing units PC with Touch Screen AEIC Ink Unit remote control cylinder circumference 14" automatic washing devices-including squeegee system Web break monitoring Ink Unit temperature control 4 AP Ink agitators 4 IST UV Dryer - Type MBS 5 80 Watt for one dryer (Printing Units) 1 IST UV Dryer - Type MBS 5 120 Watt (Coating Unit) 1 Flexo-Printing Unit for coating with base and register trolley incl. Coating supply 1 Softal Corona unit 1 BST Promark Video Web monitoring 1 Format variable punching unit Magnetic cylinder punching plate - thickness 0,44 mm Gap Master variable punching depth adjustment Electropneumatic on and off and KMS 1 KELVA CWC Web cleaning system 1 ELTEX Anti Static device with 5 Ent ionizing bars 1 Label grid rewinder - 799 mm diameter 1 Rewinder Unit - 700 mm diameter 1 Longitudinal cutting device with 4 knifes 1 Electrical equipment and control panel Condition: Very good (still in Production) Available: Immediately

Oslo Norway

Norway

Iwasaki

TR25 FVM-T-6DH

1998

Label Printing

Semi rotary Offset Label printing machine Year 1998 N. 6 colors - Waterless Web Width: 260 mm Max Print size: 200×250 mm Max mechanical speed: 5000 c/h Equipment: Unwind n. 3 Double offset units (six colors) n. 3 GS UV System dryers n. 1 Varnish/flexo unit n. 1 GS UV System dryer n. 1 Rotary die cutting unit n. 1 Hot foil unit n. 1 Laminating unit n. 1 Flat-bed die cutting unit Rewinder

Terni Italy

Italy

Miyakoshi

MLP 13A

2006

Label Printing

Offset/Flexo - intermittent label printing machine Year 2006 Web Width: 350 mm Printing Width: 330 mm Equipment: Unwinder BST control N. 5 Offset printing units + 5 UV units N. 1 Flexo printing unit + 1 UV unit N. 1 Rotary die cutting unit Video web inspection Ink control Rewinder n. 3 Anilox

Terni Italy

Italy

HP

Indigo WS 4500 + Meccanica Maggiore Spalmatore Flexo

Label Printing

Digital Label printing machine N. 7 colors Printing width: 308 mm Printing area: 308x450mm

Terni Italy

Italy

Zonten

RY 320-5

2007

Label Printing

Max Web Width: 320mm Configuration: Unwinder Web guide 5 x Flexo Printing Units 4 x IR dryers 1 x UV (interchangeable) dryer 1 x Rotary die unit Turn bar device Lamination Unit Waste device Rewinder; Accessories: Printing cylinder / 15 pcs, from 7” to 13.5” Anilox Ceramic roller / 5 pcs, from 200LPI to 1000LPI

Terni Italy

Italy

Gallus

Arsoma EM410- 6

2000

Label Printing

Max Web Width: 410 mm Configuration: Unwinder 6 x Flexo Printing Units 6 x GEW E-Brick UV dryers 2 x die cutting units Printing repeat Turning Bar Video system Rewinder

Terni Italy

Italy

Carint

Miniflex CX8

1998

Flexographic equipment

Print possibilities: 8+0 Print width 1000 mm Material width 1050 mm Gas drying system Print development 310-600 mm Automatic registers Semi automatic loader Max reel diameter (unwinder & rewinder) 800 mm. Rewinder: Turret automatic Assisted reel discharge Accessories: GUIDE ON BOARD INPUT INCLUDED ON-BOARD DRIVE IN THE OUTPUT INCLUDED VIDEO INSPECTION SYSTEM INCLUDED (BST SHS4000) ELECTRIC SHAFT INCLUDED PNEUMATIC PUMPS INCLUDED CLOSED CAMERA RACLE INCLUDED CORONA TREATMENT INCLUDED (Mero ceramico) REFRIGERATOR INCLUDED MONTACLICH MACHINE INCLUDED (BIEFFEBI Mirage 335) NR. 481 FORMAT GEARS: Annex 1 NR. 20 CYLINDERS FOR PRINT SLEEVES N.10 LIGHT 1000 N.10 LIGHT 630 Cylinders & compressors

Terni Italy

Italy

Gallus

RCS 330

Flexographic equipment

Unwinding Web cleaning Corona 10 printing stations 10 flexographic printing units 10 ink pumps 1 hot foil 1 screen printing unit 1 lamination unit 1 cold foil unit 10 Uviterno UV dryers 1 rotary die cutter 1 web video 1 rewinder Printing accessories: 336 printing cylinders 20 anilox 4 magnetic cylinders

Hude Germany

Germany

Gallus

EM 280

2000

Flexographic equipment

Gallus EM 280 Web width: 280mm Unwind Web guide Corona treater 4 x print stations, 3 Flexo + 1 Sieb 4 x IST UV dryers (2009 new) 4 x water cooled rollers 1 x hot foil unit 1 x rotary die station Waste rewind Rewind Cylinders Screen rings

Hude Germany

Germany

Gallus

ECS 340

2013

Flexographic equipment

Unwind web guide 2 sided Teknek web cleaner 8 x flexo print stations 8 x GEW UV dryers Chill rolls and Chiller included 1 x die station with rotometrics accutrack unit Waste rewind Sheeting station with delivery Rewind EL Scan inspection camera 7 x sets of print sleeves with magnetics (90, 103, 116, 126, 136, 144, 160)

Hude Germany

Germany

Gallus

EM 280

2007

Flexographic equipment

Gallus EM 280 Unwinder 2 Flexographic printing units 2 UV dryers 1 Screen printing unit 2 Die cutting units Grid winder Pulling station Rewinder Printing accessories: Print cylinder, magnetic cylinder, anilox

Hude Germany

Germany

Gallus

EMS 340

2009

Flexographic equipment

Unwinding Splice detection with acoustic warning signal Web edge control Web break control 2x Corona infeed, behind unit 4 (Vetaphone/Softal) 1x Arcotec web cleaning 8 printing platforms 8 flexographic printing units 3x screen printing units, interchangeable 2x rotary die-cutting units Scribing tool with cross cutter Rail system 1x additional winding/unwinding unit (laminate) 1 x additional cold foil embossing Insertion offset station for the production of multi-layer labels (web offset device) 8x GEW UV dryers with cooling roller Hyfra cooling machine BST video control Automatic register control Sensotec Job data management for up to 500 jobs Format length correction in the printing and processing area - Recommended for stretchable materials Grid winder Unwinding Spreading roller and pressure arm for crease-free winding of thin foils and aluminum. 1x transport trolley 2x transport trolley process change 8 change axes for Z 72 Print cylinder- Magnetic cylinder- Anilox-

Hude Germany

Germany

DCM

Babycat

2006

Flexographic equipment

No slitting, only rewind Maximum web width: 400mm Maximum unwind and rewind reel diameter: 610mm Maximum production speed: 400 m/minute Bi-directional operation Double web guide 2 synchronized motors

Romania

Accraply

ShrinkMaster S2000

2015

Flexographic equipment

Superb shrunk finish with Filled or Cold Containers Virtually Dry shrinking Fully Insulated & preheated Chassis Unique Coaxially piped shrinking nozzles to minimize condensation 12 heating areas split into two zones for complex shapes Stainless Steel Prepset & Extraction Dry Steam tunnel Minimum Conveyor Height: 900 mm Maximum Conveyor Height: 1000 mm Minimum Container Height: 50 mm Maximum Container Height: 300 mm Minimum Container Diameter: 20 mm Maximum Container Diameter: 120 mm Pressure: 5 Bar Steam Requirements: 100 - 200 kg/hour

Turkey

Accraply

ShrinkMaster S2000

2016

Flexographic equipment

Ultrasonic sleeve-width measuring device provides precise layflat monitoring On-machine layflat reporting and quality reports Intuitive touchscreen controls with unlimited recipes Internet based remote diagnostic with WiFi capability Turret-ready expansion ports on electrical cabinet Stanford AccraSeamShrink Sleeve Seamer Web speed up to 600 mpm Fully automated layflat adjustment with precise servo-controlled movement Servo solvent dispense system precisely adjusts the flow of solvent during acceleration and deceleration Touch-of-a-button cleaning of the solvent system Forms and seals PVC, PET, PETG, OPS and PLA films Minimum Layflat Width: 50mm Maximum Layflat Width: 305 mm Maximum Web Speed: 600 m/minute Maximum Unwind Diameter: 762 mm Maximum Rewind Diameter: 610 mm Tension: 0.26 Kg/ cm Total Minimum Tension: 1.7 Kgf

Turkey

Accraply

Stanford DM12

2016

Flexographic equipment

Automatic inspections for seam integrity, solvent presence and splice/flag detection. Two-motor smart AC Vector drive system On-board drive-based PAC Control Internet-based remote diagnostic with WiFi capability Stanford DM12 Shrink Sleeve Inspector Manual inspection button with return-to-defect Intuitive touchscreen controls with unlimited recipes Electronic rewind oscillation up to 20 mm Cantilevered compact design Reversible over/under winding Minimum Layflat Width: 50mm Maximum Layflat Width: 305 mm Maximum Web Speed: 500 m/minute Maximum Unwind Diameter: 610 mm Maximum Rewind Diameter: 610 mm Tension: 0.26 Kg/Cm Total Minimum Tension: 1.58 Kgf

Turkey

Remak

RE 2x80

2002

Flexographic equipment

Used flexo printing machine Maximum width: 800 mm 2 colors 2+0; 1+1 Materials: PE, PP, BOPP, CPP, PET, PVC, AL, Paper Manual control for foil unwinding Printing cylinders: 32-2 pieces, 35-2 pieces, 36-2 pieces, 40-2 pieces, 45-2 pieces, 50-2 pieces, 55-2 pieces, 60-2 pieces.

Romania

Arsoma

EM-410

1989

Flexographic equipment

8 printing units: 2 colors UV in production, the other printing units dismantled in the warehouse(from one year ago) 8x dryer with warm air 1x UV drying double IST lamp (varnishing) 8x ink pump 2x die-cutting unit (magnetic cylinder die-cutting) Knife unit for side cutting (shear knife) Maximum web width: 410 mm Core diameter: 76 mm Maximum Outside diameter: 1000 mm (infeed) Maximum Outer diameter: 1000 mm (outlet) Column lifter for magnetic cylinder Turret rewinder tr450 ( + 40mm core feeder )

Poland

Arsoma

EM 220

1991

Flexographic equipment

8 printing units: 4 colors UV in production, the other units dismantled in the warehouse(from one year ago) 4x dryer with warm air 3x UV dryer 1x UV drying double IST lamp (varnishing) 8x ink pump 2x die-cutting unit (magnetic cylinder die-cutting) Knife unit for side cutting (shear knife) Maximum web width: 220 mm Core diameter: 76 mm Maximum Outside diameter 1000 mm (infeed) Maximum Outer diameter 720 mm (outlet) Pile stacking device Column lifter for magnetic cylinder

Poland

Rotoflex

VLI 330

2007

Flexographic equipment

Roll-to-roll label inspection and rewinding machine Maximum web width: 330 mm Maximum speed: 305 m/minute Unwind Capacity: 711 mm Rewind Capacity (Single-Spindle): 457 mm Rewind Capacity (Dual-Spindle): 406 mm Configuration: Rewind shaft Unwind shaft Web guide/Splice Table Draw station Crush Knife unit Shear Knife unit Razor blade unit Jog & Rewind deflate pedal Auto web gripper Unwind adjustable splice table Strobe light Front inspection C3/URC counter Air control panel Web gripper activation switch Leveling foot Side job Pedal Roll End Sensor Rewind direction change switch

Ecuador

Carint

Gemini 1587

1987

Flexographic equipment

Printing Repeat: 370 -780 mm Maximum working width: 1100 mm Minimum working width: 600 mm 6 colors Maximum speed: 100 m/minute Good running Condition

Malaysia

Aquaflex

DBSP 806

1991

Flexographic equipment

16600 working hours 6 Colors Hot air IR dyers Print width: 8 inches GEW UV/HG lamp on the 6th print station Web turn bar Delam/Relam Set of pneumatic air circular slitter knives Control Fife Web guide 3 x die-cut stations 3 x waste wind-up shafts Manual Print Register Double final product rewinders 6 ink pumps Spanish parts manuals 77 Print Plate rolls available with the press: from 53 to 176 teeth, 1/8” cp. 15 Anilox rolls available with the press: from 200 to 813 Lpi Electrical details: Voltage: 240V. Cycles: 60 Hz. , Amps : 145 , KVA : 57 , Air : 100 PSI , Phases : 3PH

Colombia

GSP

Label PRO 450

2002

Flexographic equipment

Roll to sheet A4, A3 Maximum width: 440 mm Magnetic cylinder: 187 Teeth =593,725mm /A4 = 296.8625 mm/

Poland

ABG

Digicon 2

2011

Flexographic equipment

Unwinder Flexo unit Semi-rotary die-cutting 25” 2 rewinders Maximum roll diameter: 700 mm Maximum running speed: 36 m/minute Minimum plate cylinder flexo: 254 mm Maximum plate cylinder flexo: 609 mm Maximum rewind diameter: 600 mm Web Width: 330 mm

Italy

Karlville

K1 Seam 200

2011

Flexographic equipment

PLC Controlled shrink sleeve seamer with touch screen operator interface capable of seaming PVC, PET, OPS, PLA shrink films Maximum speed: 200 m/minute Unwind width: 420mm 3" OD pneumatic core chucks and a 55mm to 200mm lay flat finished rewind at standard industry tolerances. Wick solvent application Adjustable forming plate 8 forming side wheels 2 forming fingers Anti-static brush 420 mm OD cantilevered roll capacity with oscillating rewind control Voltage AC 1 Phase, 200 V, 60 HZ, 10 A

United States

Rotocontrol

RC 200

2015

Flexographic equipment

No die-cutting Broken display Finishing machine - Slitting machine Unwind & Rewind shaft for 76,2 mm core Maximum width: 390 mm Eltex Antistatic system AVT Helios Inspection system

Romania

GM

DC330 V5

2010

Flexographic equipment

Finishing machine for labels Width: 330 mm Semi and full rotary die-cutting unit Semi and full rotary flexo unit Lamination Unit Cold foil unit New GEW UV Lamp in the machine, one new spare GEW UV lamp Refurbished Nip rollers New GM metal rollers

Albania

XL Plastics

Superflex 550

2017

Flexographic equipment

6 colors Maximum width: 600 mm Printing width: 560 mm Materials: PE, PP, BOPP, CPP, PET, PVC, AL, paper Printing cylinders: 320 - 6 pieces, 360 - 6 pieces, 400 - 6 pieces, 450 - 6 pieces, 500 - 6 pieces, 530 - 6 pieces, 600 - 6 pieces Mechanical speed: 130 m/ minute

Romania

ABG

Digicon 2

2008

Flexographic equipment

Overhauled Machine built to work right to left Unwind -700 mm unwind, electronic web guide (edge guide sensor) splice table and web clamps, auto brake tension control. -Roll lift for 700 mm unwind -Corona treatment Vetaphone Infeed nip drive section, infeed dancer. Semi rotary flexographic printing station with quick change cassette comprising stainless steel ink pan, pick up roller, ceramic anilox roller and reverse angle doctor blade. The station has auto pre-positioning and servo drive re-register -1 x Coating Cylinder 11” (coating width 320 mm) -1 x Anilox rollers 400LPI (6,77 cm3/m2) -GEW air cooled UV curing unit 160 w/cm -Hot air drying system Over laminating tower with waste carrier rewind Mid press dancer to allow full rotary coating Semi rotary die cutting station with 19” magnetic cylinder (18” maximum repeat). -Kocher & Beck Gapmaster Outfeed nip drive section, outfeed dancer. Waste matrix stripping (maximum diameter 600 mm) Rewind -Scissor slitting including 5 knives and removable knife shafts -Back Scorer used for edge trimming the silicon carrier, which is then rewound with the matrix. -Single spindle rewind with variable tension control, 76mm air expanding shaft -label length counter with batch and pause facility -Second rewind shaft with 76 mm shaft Maximum web width: 330 mm Minimum web width: 180 mm Maximum repeat length: 457,2 mm Minimum repeat length: 50,8 mm Rewind maximum diameter: 500 mm

Spain

HP

Indigo WS 4500 + Meccanica Maggiore Spalmatore Flexo

2008

Label Printing

Package: 1.HP Indigo WS 4500 - 2008 – in production HP indigo WS 4500 – 2007 – for spare parts Meccanica Maggiore Spalmatore Flexo - 2020 HP Indigo WS 4500 2008 150 milion impressions In production Printing speed: 16 m/minute (4 colors) – 32 m/minute (1 – 2 colors) Maximum material width: 330 mm Minimum material width: 200 mm Maximum printing width: 308 mm Maximum print repeat: 450 mm Substrate thickness: 20 – 350 microns Resolution: 812 x 812 dpi / 812 x 1624 dpi HP indigo WS 4500 2007 complete (except for the rewinder) not in operation Meccanica Maggiore Spalmatore Flexo 2019 Small machine with IR oven to do prime paper Working with Michelman primer

Italy

Ofem

Columbus 10

1999

Flexographic equipment

6 colors Geared Film and paper printing by solvent-based inks Maximum printing width: 1000 mm Web width: 1050 mm Print repeat: 290 - 850 mm Speed: 250 m/minute Unwinder type: double bracket Maximum diameter unwinder: 800 mm Rewinder type: Turret Max diameter rewinder: 800 mm 6 pneumatic pumps Central drum Hastelloy coating 4 sets of cylinders complete with gears (suitable for 2.54/2.84 clichés) with print developments of 290 mm, 500 mm, 580 mm, 700 mm) 5 rubberized cylinders for full printing job for width 800 mm(2),970 mm(2), 1010 mm Aniloxes: 1 x 80/20, 5 x 160/12, 2 x 140/14 Web guide in entrance and exit Inking system: 4 stations closed chamber 2 station fountain roller Electric drying system Spare part: main engine drive External viscometer group The machine is currently not visible in operation It is electrically disconnected but still mechanically mounted. Drying system IMECO - needs to be repaired

Italy

KDO

K22

2008

Flexographic equipment

Maximum width: 265mm Turn bar Delam/relam 7 Printing Units with UV/IR Drying UV GEW Cold foil 2 Web guide systems (one behind the unwinder and the other one in front of the die-cutting unit) K1 Tectonic 2 Rewinders Lamination BST 3 Die-Cutting Units Set of printing cylinders, magnetic cylinders, and anilox rollers Circular knives for longitudinal cutting Additional cross for the web reversing

Poland

Rotocontrol

RSC 440

2016

Flexographic equipment

No die-cutting Finishing machine - Slitting machine Inspection camera E&L Maximum web width: 420 mm Core diameter: 76,2 mm

Romania

MGI

Jet Varnish 3DS

2017

Label Printing

Counter: 1.1 million sheets No iFoil module Paper thickness: 135 - 450 g/sqm Minimum format: 21x30 cm Maximum format: 36.4x102 cm Production speed: 2300 A3/hour New belt Disassembled and in boxes

France

Smag

Gal Mixte

2007

Flexographic equipment

First installed in 2007 Fully refurbished and rebuilt to a new configuration in 2014 The part of the refurbishment was all the servo motors and the full control system Label finishing machine for sale Counter: 115.000 m Configuration: unwinder screen printing hot air and UV curing Vetaphone corona flexo semi-rotary cold foil/lamination unit shear knife slitting rewinders

Hungary

Find the Right Equipment

Kindly add details of the equipment you seek; and you shall find. Our community of manufacturers, sellers, and professionals will procure it for you.

Click Here

The World of Print at your Fingertips

The Machine Dalal Mobile Apps

Download our Machine Dalal App Regular updates from our magazine with illustrations, innovations , commodities, history, media, art and a whole lot more from the magnificent world of Print.

Get the App

Login

Login