Popular Brands Or view all

Bag making Machinery for Sale | Preowned & Preloved

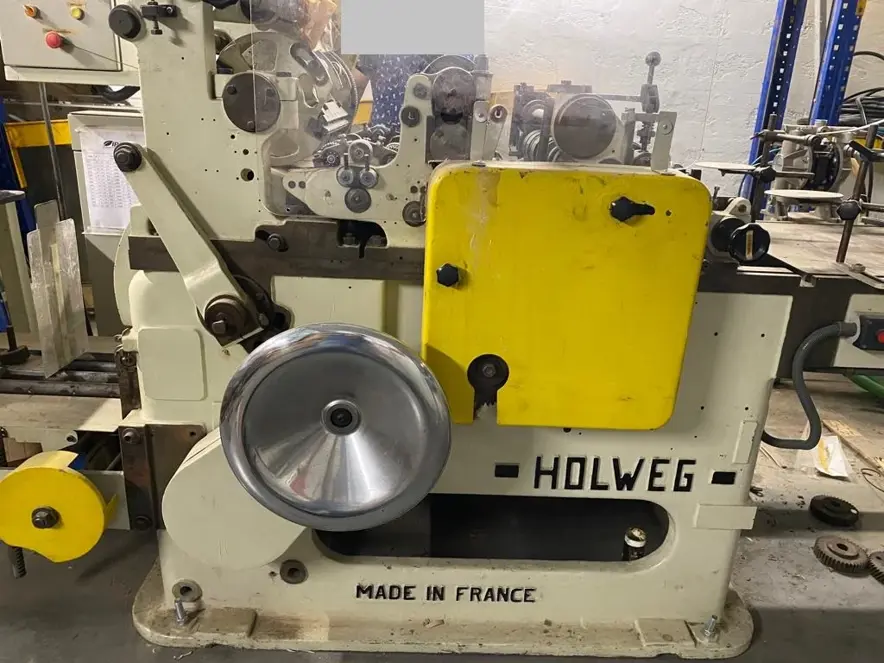

Holweg

RS 2

Bag making

Around 1970 Bag width: 70-380 mm Bag length: 160-680 mm Bag side width: 20-90 mm Cutting length: 170-690 mm Folding button: 10-30 mm In-line printer: 3 colors Maximum speed: 400/800 bags/minute Paper thickness: 30-100 gr/sqm Paper width max: 900 mm Paper reel diameter: 1.050 mm Paper reel core diameter: 76 mm Dismantled

Serbia

Hudson Sharp

FMC 3750W

1998

Bag making

Used FMC Wicket Machine Maximum working material width: 710 mm Maximum draw length: 390 mm Computer and touch screen Possibility to adjust the tension of material between front and rear draw rollers This wicket equipment includes: Driven unwind stand: - Width: 1500 mm - Maximum reel diameter: 1000 mm - Motorized edge guide included Folding triangle motorized, equipped with bottom gusset Main machine equipped with: - Hole punchers for wicket - 2 sets - Side-weld head - 2 sets of 6 collecting wicket arms (important for long bags) - Vacuum pump Accessories : INLINE Hot Pin Unit LINEAR PERFORATION UNIT Bag sizes: Width: 100-400 mm Length ( lip included ): 210-700 mm Average working Speed: 250 bags/ minute Maximum speed: 300 bags/ minute The machine is with 3 motors and servo-motors : - One motor for sealing head - One motor for front draw rollers - One motor for rear draw rollers

Egypt

DCM

ATN IM 183

2018

Bag making

2 colors Width: 600 mm Printing on each cylinder rotation: 600x525 mm2 Printing on two-cylinder rotations: 600x525 mm2 Minimum bag length: 100 mm Maximum thickness of material: - standard: 2.5 mm - automatic lifting-up system: 8 mm Maximum stereo size: 500x480 mm2 Stereo Thickness: 3 mm Machine speed: 1200-2400/ hour

Hungary

Totani

ST 24

2012

Bag making

Spout inserter Configuration: Supply Conveyor Pouch Carrier Pouch Supply and ejection unit Corner Cutter Opening Edge Sealer and Cooler Spout Supply Unit The preheater

Germany

Jianshe

ZD QFP14B/18B

2015

Bag making

Fully auto sheetfed square bottom paper bag machine Paper width: 550-1050 mm Paper length: 340-630 mm Paper grammage: 100-250 g/sqm Bag width: 180-350 mm Bag height: 240-480 mm Bag bottom: 80-170 mm Working speed: 80 pieces/minute Total power: 13 kw

Greece

Hudson Sharp

5750W

2014

Bag making

FMC Wicket Bag Machine Working condition Maximum speed: 400 pieces/minute Hand-held equipment Bag width: 100 - 400 mm Bag Length: 200 - 710 mm Material BOPP , CPP , PE , laminated PP + PE, BOPP + BOPP , BOPP + PE

Turkey

FUJI

SPM 0018/ PV 60/ R36 OT/P /Pas 0050

2008

Bag making

Fuji Astec SPM 0018 (2008) Fuji Astec PV 60(2008) Fuji Astec R36 OT/P S (2008) Fuji Astec Pas 0050(2008) Wilco Wilcomat R 36 OT/P(2008) Configuration: Feeder with vibrational drum Applicator Leakage tester Hanger

Poland

Totani

BH 60D LLLS

2008

Bag making

Width: 200-600 mm Maximum length: 500 mm Unwinding dimensions: Maximum diameter: 800 mm Maximum width: 1200 mm Maximum number of cycles: 180 cycles/minute Smooth film Maximum number of cycles: 240/minute - feed: 140 mm 220/minute - feed: 170 mm 200/minute - feed: 205 mm 180/minute - feed: 255 mm Printed film Maximum number of cycles: 240/minute - feed: 125 mm 220/minute - feed: 155 mm 200/minute - feed: 185 mm 180/minute - feed: 235 mm Heater and cooler Heater longitudinal(feed direction) Effective welding length: 600 mm - 5 units Longitudinal cooler(feed direction) Effective cooling length: 500 mm -5 units Transverse heater(wide direction) Effective welding length: 600 mm-2 units Longitudinal cooler(wide direction) Effective cooling length: 600 mm - 1 unit Transverse sealing bar - maximum welding width: 80 mm Longitudinal sealing bar - maximum welding width: 50 mm

Germany

Mamata

Vega 820

2011

Bag making

Designed for the production of zipper doypack pouches, sachets, as well as Stabilo-type pouches (without zipper). Packaging type: Zipper doypack, sachet, Stabilo 15,000 operating hours Included: Water cooler (chiller) for seal cooling PEARL punching tool for creating round holes in doypacks Die-cutting sets for: Euro-holes, Easy-open features, Rounded corners, Pencil notches Two parallel zipper preheating stations (for increased performance) Capability to seal three webs simultaneously Possibility to produce Stabilo-type pouches (without zipper) Functional Capabilities: Production of Doypacks, 3-side seal bags, and Stabilo pouches (no zipper) Three-web operation (top/bottom webs + middle insert for gussets or ZIP) Double preheating ZIP stations for higher throughput Transverse and longitudinal sealing (metal/metal and metal/rubber, up to 40 mm seal width) Full servo-drive system: index, seal, cut, tension, ZIP Die-cut modules: Euro-hole, V-notch, easy-open, rounded corners Mechanical speed: up to 210 cycles/minute Film width: up to 1520 mm Pouch width: up to 820 mm Draw length: up to 610 mm (or up to 1220 mm in skip mode) Suitable for mono-materials and multi-layer laminated films

Poland

Zenbo

ZB1260S-450

2019

Bag making

Automatic Paper Bag Making Machine 3 types of handles Maximum sheet format: 1200x600 mm Minimum sheet format: 620x350 mm Sheet weight: 120-190 g/sqm Bag width: 200-450 mm Bottom width: 80-170 mm Bag length: 250-540 mm Top turn in size: 40-60 mm Handle patch length: 188.5 mm Handle patch width: 30-50 mm Handle patch weight: 140-350 g/sqm Handle patch roll width: 60-100 mm Twist rope diameter: 4-6 mm Twist rope height: 170-195 mm Maximum Production speed: 70 bags/minute

Slovenia

New Long

335T-MII-305 THD

2003

Bag making

Sheet width: 600-1050 mm Sheet length: 400-600 mm Paper weight: 100-120 g/sqm Bag width: 220-350 mm Bag length: 290-470 mm Bottom width: 65-160 mm Tube length: 340-540 mm Interval of holes: 80-120 mm Maximum speed: 70 bags/minute

South Korea

New Long

TS5525-S+2H

2014

Bag making

Bag size Bag Width: 100-200 mm Bottom width: 60-140 mm Finished Length: 205 – 510 mm Cutting length: 260-550 mm Sheet size Maximum sheet width: 810 mm Maximum diameter: 1200 mm Sheet basis weight: Inner layer paper: 50-70g/sqm Outer layer: 60-90g/sqm Paper tube inner diameter: 70 mm Bottom sheet size Maximum sheet width: 200-240 mm Maximum diameter: 600 mm Sheet weight: 70-90g/sqm Paper tube inner diameter: 76 mm Maximum productivity: 120 - 240 bags/minute

South Korea

Somtas

tc1846

2022

Bag making

Speed: 500 m/minute Maximum Paper Reel width:1600 mm Paper Reel inner diameter: 76 / 152 mm Maximum paper reel diameter: 1650 mm Minimum cutting width: 50-70 mm Maximum cutting width: 1000 mm Paper thickness: 30-250 g/sqm Maximum Reel weight: 1800 kg Nordson Gluing pump

Turkey

Find the Right Equipment

Kindly add details of the equipment you seek; and you shall find. Our community of manufacturers, sellers, and professionals will procure it for you.

Click Here

The World of Print at your Fingertips

The Machine Dalal Mobile Apps

Download our Machine Dalal App Regular updates from our magazine with illustrations, innovations , commodities, history, media, art and a whole lot more from the magnificent world of Print.

Get the App

Login

Login