Gallus Preloved and Preowned

Gallus Preloved and Preowned

Gallus

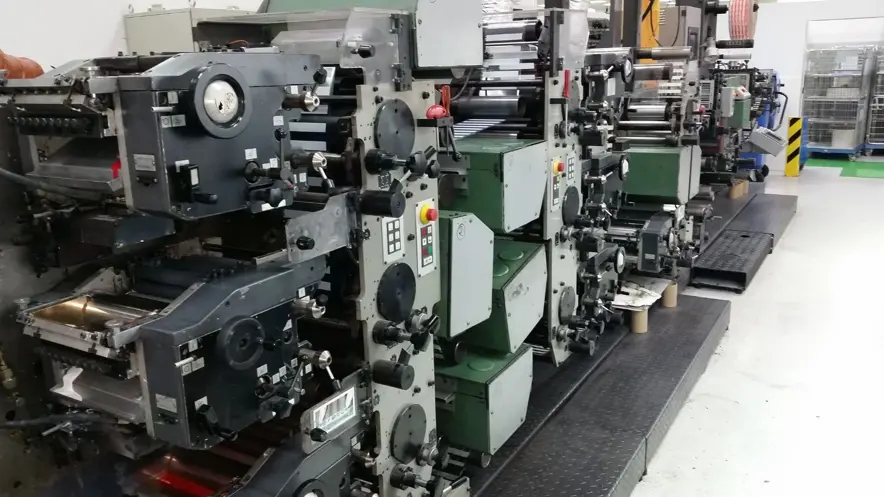

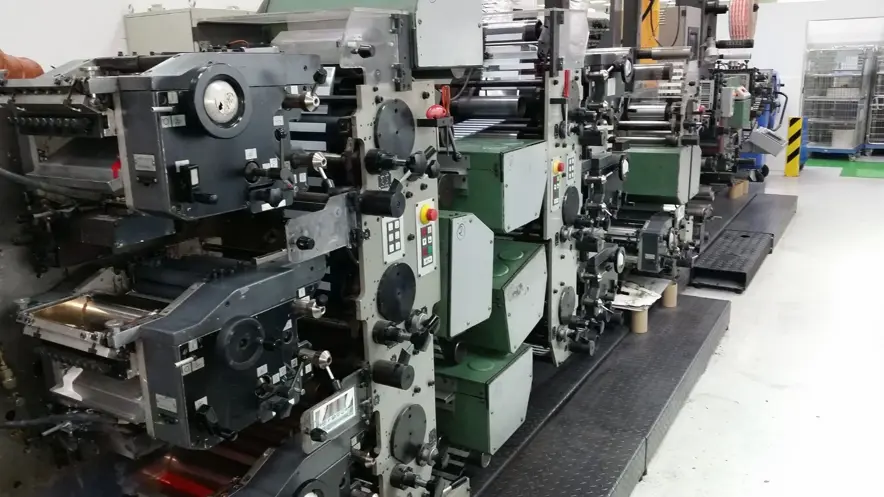

Arsoma EM410- 6

2000

Label Printing

Max Web Width: 410 mm Configuration: Unwinder 6 x Flexo Printing Units 6 x GEW E-Brick UV dryers 2 x die cutting units Printing repeat Turning Bar Video system Rewinder

Terni Italy

Italy

Gallus

RCS 330

Flexographic equipment

Unwinding Web cleaning Corona 10 printing stations 10 flexographic printing units 10 ink pumps 1 hot foil 1 screen printing unit 1 lamination unit 1 cold foil unit 10 Uviterno UV dryers 1 rotary die cutter 1 web video 1 rewinder Printing accessories: 336 printing cylinders 20 anilox 4 magnetic cylinders

Hude Germany

Germany

Gallus

EM 280

2000

Flexographic equipment

Gallus EM 280 Web width: 280mm Unwind Web guide Corona treater 4 x print stations, 3 Flexo + 1 Sieb 4 x IST UV dryers (2009 new) 4 x water cooled rollers 1 x hot foil unit 1 x rotary die station Waste rewind Rewind Cylinders Screen rings

Hude Germany

Germany

Gallus

ECS 340

2013

Flexographic equipment

Unwind web guide 2 sided Teknek web cleaner 8 x flexo print stations 8 x GEW UV dryers Chill rolls and Chiller included 1 x die station with rotometrics accutrack unit Waste rewind Sheeting station with delivery Rewind EL Scan inspection camera 7 x sets of print sleeves with magnetics (90, 103, 116, 126, 136, 144, 160)

Hude Germany

Germany

Gallus

EM 280

2007

Flexographic equipment

Gallus EM 280 Unwinder 2 Flexographic printing units 2 UV dryers 1 Screen printing unit 2 Die cutting units Grid winder Pulling station Rewinder Printing accessories: Print cylinder, magnetic cylinder, anilox

Hude Germany

Germany

Gallus

EMS 340

2009

Flexographic equipment

Unwinding Splice detection with acoustic warning signal Web edge control Web break control 2x Corona infeed, behind unit 4 (Vetaphone/Softal) 1x Arcotec web cleaning 8 printing platforms 8 flexographic printing units 3x screen printing units, interchangeable 2x rotary die-cutting units Scribing tool with cross cutter Rail system 1x additional winding/unwinding unit (laminate) 1 x additional cold foil embossing Insertion offset station for the production of multi-layer labels (web offset device) 8x GEW UV dryers with cooling roller Hyfra cooling machine BST video control Automatic register control Sensotec Job data management for up to 500 jobs Format length correction in the printing and processing area - Recommended for stretchable materials Grid winder Unwinding Spreading roller and pressure arm for crease-free winding of thin foils and aluminum. 1x transport trolley 2x transport trolley process change 8 change axes for Z 72 Print cylinder- Magnetic cylinder- Anilox-

Hude Germany

Germany

Gallus

R300 B

1994

Letterpress

Fully refurbished in 2009, and the UV system has been replaced with a new one, UV Ray Unwind unit 6 letterpress units 1 hot foil 1 varnish unit Flatbed die-cutting unit Rotary die-cutting unit Waste matrix rewinder Outfeed section Automatic register control Web video inspection system Printing cylinder sets z 96, 110 , 114, 117 , 121, 126 , 129, 135 ,138, 142, 152, 158, 162, 164, 169, 172, 184

Bulgaria

Gallus

R 200 B

1996

Letterpress

Maximum web width: 205 mm 1 x unwind with splice tables 2 x double-sided Teknek web cleaners 8 letterpress printing units Gallus UV drying (7 lamps) with water-cooled path rollers Maximum printing repeat: 457.2 mm Maximum printing width: 203 mm De-lam re-lam facility for printing up to 2 colors on the adhesive side Flatbed die-cutting 2 rotary die-cutting position Overhead hoist for changing mag cylinders Maximum die-cutting repeat: 457.2 mm Minimum die-cutting repeat: 171.4 mm Matrix waste rewind Razor slitting Sensotec auto register control Product rewind Good selection of tooling and spare parts included

Bulgaria

Gallus

R 200 B

2002

Letterpress

Maximum web width: 205 mm 1 x unwinds with splice tables 1 x double-sided Teknek web cleaners 10 printing units 8 letterpress printing units 2 screen printing units IST UV drying (9 lamps) with water-cooled path rollers Maximum printing repeat: 457.2 mm Maximum printing width: 203 mm De-lam re-lam facility for printing up to 2 colors on the adhesive side Flatbed die-cutting 1 rotary die-cutting station Overhead hoist for changing mag cylinders Maximum die-cutting repeat: 457.2 mm Minimum die-cutting repeat: 171.4 mm Matrix waste rewind Razor slitting Sensotec auto register control Product rewind

Bulgaria

Gallus

TCS 250

2005

Label Printing

Printing Printing width max.: 254 mm - 10" Repeat length max.: 254 mm - 10" Repeat length min.: 101,6 mm - 4" Repeat length increment. 3,175 mm - 1/8" Flat processing Processing width max.: 254 mm - 10" Repeat length max.: 254 mm - 10" Repeat length min.: 101,6 mm - 4" Repeat length increment. 3,175 mm - 1/8" Substrates PS-Materials standard Paper 100 - 180 g/m² Carton/Board up to 300 g/m² with max. thickness 0,3 mm - 0.012" Specificatio of Printing Units 1 Unwind Unit with Web guide 6 Offset printing units 6 UV Dryer 1 Hot Stamping Unit 1 Serigrafic Unit 1 Embossing Unit 1 Die-Cutting Unit 1 Wast-Rewinder 1 Rewinder

Oslo Norway

Norway

The World of Print at your Fingertips

The Machine Dalal Mobile Apps

Download our Machine Dalal App Regular updates from our magazine with illustrations, innovations , commodities, history, media, art and a whole lot more from the magnificent world of Print.

Get the App

Login

Login