Bobst Preloved and Preowned

Bobst Preloved and Preowned

1983

Bobst

SP 102 E

1983

Die cutting

autoplatine, die cutting machine. Year 1983 max 102x720 min. 40x35 speed 7.500 s/h pressure 250 t. Stripping device

Provincia di Siena Italy

Italy

Bobst

SP102EII

1998

Die cutting

ZOHK

Guangzhou China

China

Bobst

SP 102-SE

1998

Die cutting

ZOHL

Guangzhou China

China

Bobst

SP EVOLINE 102-E

2008

Die cutting

XQHE

Guangzhou China

China

Bobst

SPO 1575 EEG - 350 T

1994

Die cutting

ZEPK

Guangzhou China

China

Bobst

SPO 1600

1989

Die cutting

overhauled on 2009 Maximum size 110x160 cm Minimum size 52x60 cm For cardboard min 1 mm , corrugated max 9 mm Maximum speed 6.000 sheet per hour Vacuum feeder Stripping sections with tools

Terni Italy

Italy

Bobst

SP 102-SE

1993

Die cutting

Suitable for cardboard and corrugated up to max 4 mm Sizes: max 102x720 - min. 40x35 Pallet feeder Pull side lay OS Centerline Stripping unit

Terni Italy

Italy

Bobst

SP 102 Evoline

1983

Die cutting

autoplatine, die cutting machine. Year 1983 max 102x720 min. 40x35 speed 7.500 s/h pressure 250 t. Stripping device

Terni Italy

Italy

Bobst

SP 142 CER II

2000

Die cutting

Maximum size 102 x 142 cm Minimum size 50 x 70 c Maximum pressure cutting 550 T Maximum speed 8.000 sheet hour Special corrugated device Pallet feeder with Automatic non stop by grill Side lay OS, Movable stop with electronic control Side lay OOS, Pushing side lay Centerline Chase loader 2 cutting chase Bernoulli device Stripping section Quick lock stripping Blanking section Quick lock blanking Delivery non stop automatic pallet change

Terni Italy

Italy

Bobst

Media 45-II

1999

Folder Gluer Machines

Straight line n. 1 disc gluing point Delivery with pressure belts

Terni Italy

Italy

Bobst

145 Matic

1987

Folder Gluer Machines

Max size 1000x1450 mm Min size 360 x 120 mm Straight line Crash lock bottom 4/6 corners device n. 1 disc gluing point Nordson gluing system: n. 4 cold gluing guns n. 2 hot gluing guns Delivery with pressure belts

Terni Italy

Italy

Bobst

SP 102 Evoline

2002

Die cutting

XQQK

Guangzhou China

China

Bobst

SP 102 E

1981

Die-cutters- automatic and handfed

We are pleased to offer: Used BOBST SP-102-E Die Cutter Year 1981 Specification The Bobst SP 102 E is a legendary industry-standard automatic die-cutting press, renowned for its precision, durability, and high productivity in the folding carton and commercial print sectors. This specific machine, a 1981 model, carries the prestigious "Autoplaten SP 102-E" designation, signifying Bobst's world-leading automatic platen technology. A significant advantage of this particular unit is that it has been Reconditioned by Graphicwest, a specialist company globally recognised for their expertise in refurbishing Bobst machinery. This reconditioning ensures that while the machine maintains its robust 1981 build quality, it operates with the reliability and accuracy required for modern production environments. The "E" specification indicates the inclusion of a full stripping station, allowing for the automatic removal of internal waste and side/rear trim, which significantly streamlines the finishing process. Model Autoplaten: SP 102-E Max. Sheet Size: 1,020 × 720 mm Min. Sheet Size: 400 × 350 mm Max. Die-Cutting Size: 1,020 × 705 mm Max. Pressure: 250 tonnes (2.5 MN) Max. Speed: 7,500 sheets/hour Paper Min. Weight: 80−90 g/m2 Board Max. Thickness: Up to 2,000 g/m2 Corrugated Board: Up to 4 mm Condition: Reconditioned by Graphicwest Made in Switzerland Good working order Available immediately

Ringwood United Kingdom

United Kingdom

Bobst

SP 102-SE

1996

Die cutting

ZSGH

Guangzhou China

China

Bobst

SP 102-SE

1999

Die cutting

ZSGG

Guangzhou China

China

Bobst

SP 102-SE

1996

Die cutting

ZSGE

Guangzhou China

China

Bobst

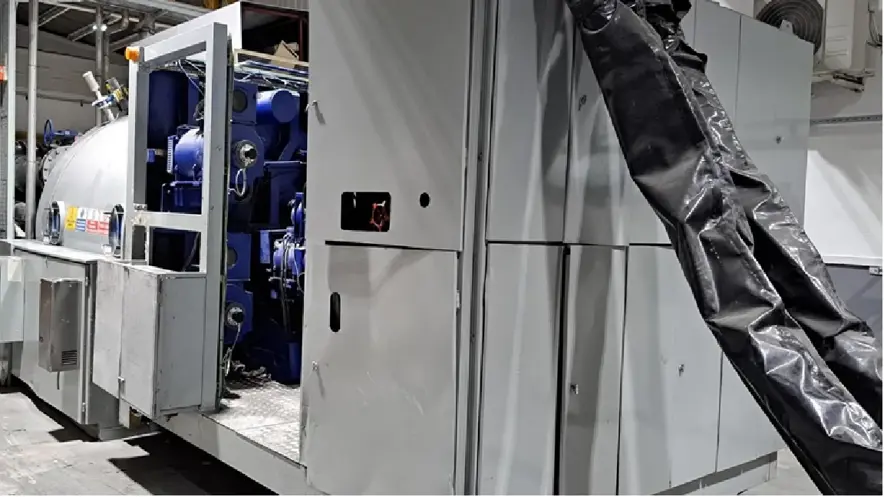

(GVE) – EHF 1650 metallizer

1994

Hot foil embossing machines

Used Bobst Metallizer Refurbished recently Maximum roll Diameter: 1000 mm Web width: 700 - 1650 mm Maximum line speed: 720 m/ minute Unwind tension: 20-362 (N) Rewind tension: 20 -362(N) DTR2 Torque: 0- 741 Rewind Layarm Mode Gap: 0-50 mm DTR1 Torque: 0 - 66

Egypt

Bobst

Rotoextruder 400F 1300/400

2017

Film processors

For extrusion coating and laminating BOPP, PET, PA, OPA, PE, Paper, Laminated materials Web width: 650- 1300 mm Mechanical speed: 400 m/minute Minimum operating speed: 50 m/minute Web direction - from left to right Minimum temperature: 230 °C Minimum pressure: 6 bar

Hungary

Bobst

SPanthera 106 LE

2004

Die cutting

Equipment: Stripping station Optical register sheet infeed Automatic pile feeder adjustment double sheet control ultrasonic Centerline 1 micrometric plate 1 plate 4 mm 2 frames closed Quick Lock stripping Non-Stop delivery make ready table

Oslo Norway

Norway

The World of Print at your Fingertips

The Machine Dalal Mobile Apps

Download our Machine Dalal App Regular updates from our magazine with illustrations, innovations , commodities, history, media, art and a whole lot more from the magnificent world of Print.

Get the App

Login

Login