23/04/2025

What are the types of Die Cut Machine?

Discover the various die cut machines available, each designed for specific materials, volumes, and precision levels.

Die cutting is a versatile manufacturing process used to cut, shape, or engrave materials into precise designs and components. From packaging and automotive parts to intricate crafts and electronics, die cutting plays a crucial role in many industries. But not all die cutting is the same—various methods exist, each suited to different materials, volumes, and applications. In this article, we’ll explore the main types of die cutting, their advantages, and common questions, plus suggest content for infographics to help visualize the process.

Main Types of Die Cutting

Flatbed Die Cutting

How It Works:

Flatbed die cutting uses a flat die that stamps down onto the material (much like a cookie cutter). The die is mounted in a hydraulic or mechanical press, which applies pressure to cut the material into the required shape.

Best For:

Thicker, rigid materials (e.g., rubber, plastics, heavy cardstocks)

Low-to-medium volume projects

Projects requiring quick tool changes or prototypes

Advantages:

Handles a wide range of material thicknesses

Lower tooling costs and faster setup

Ideal for projects needing tight tolerances and clean edges

Limitations:

Slower than rotary die cutting for high-volume production

Not as efficient for continuous roll materials

Rotary Die Cutting

How It Works:

Rotary die cutting uses cylindrical dies mounted on rollers. As the material passes through the rotating cylinders, the die continuously cuts, perforates, or scores the material.

Best For:

High-volume, continuous production

Thin, flexible materials (e.g., films, foams, tapes, labels)

Applications requiring multiple processes (cutting, laminating, slitting) in one pass

Advantages:

High speed and efficiency

Tight tolerances and consistent results

Can combine several processes in a single run

Limitations:

Higher initial tooling costs

Best suited for flexible, roll-fed materials

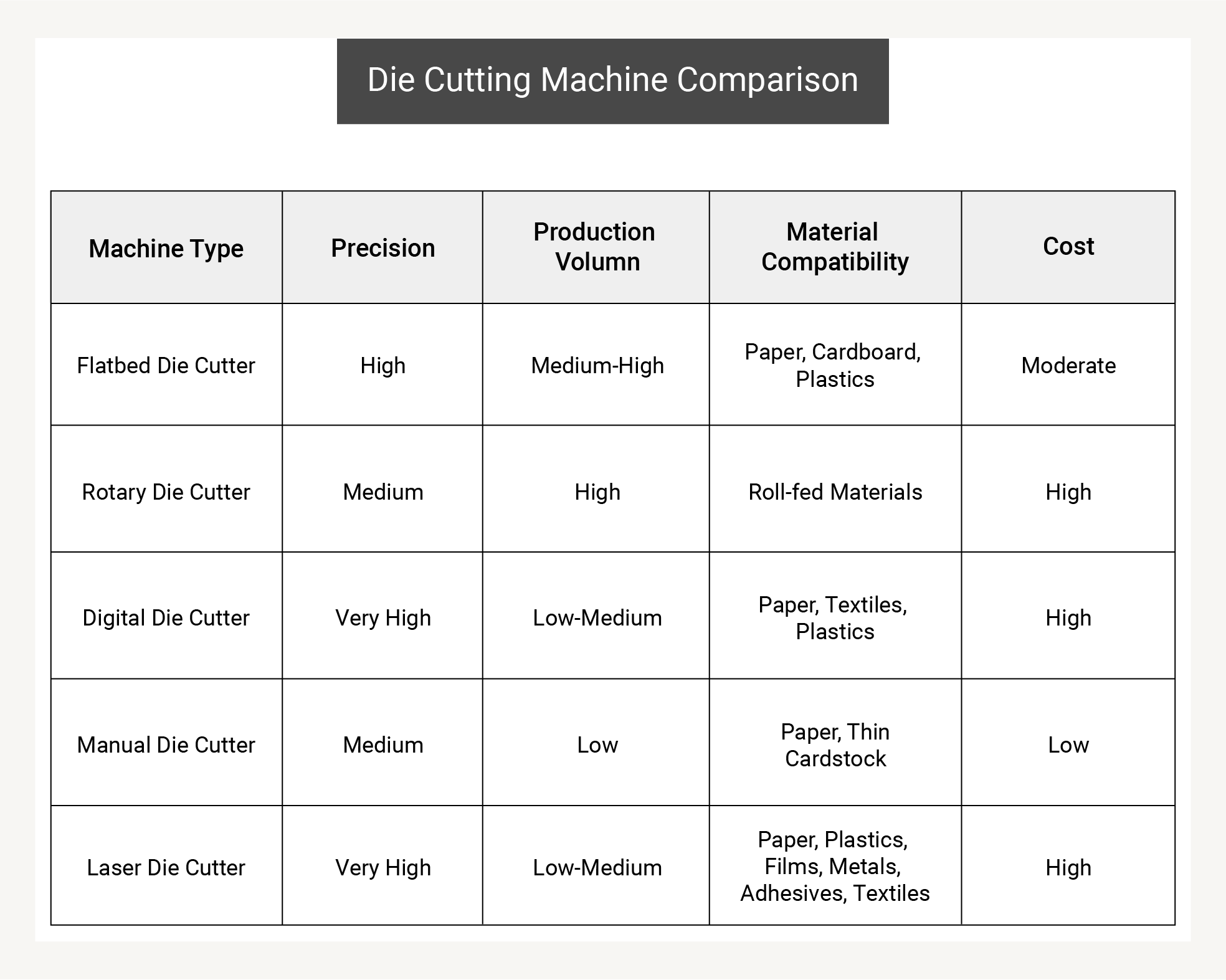

Die cutting machines comparison

Die cutting machines comparison

Laser Die Cutting

How It Works:

Laser die cutting uses a focused laser beam to cut or engrave materials without physical blades. The laser follows a programmed path to create intricate designs1.

Best For:

Highly detailed, complex shapes

Rapid prototyping and short runs

Materials sensitive to pressure or heat

Advantages:

No physical tooling required—design changes are easy

Extremely precise and clean cuts

Can cut, engrave, and perforate in one process

Limitations:

Slower than rotary for high-volume production

Not suitable for all materials (some may burn or melt)

Digital Die Cutters

How It Works:

Digital die cutters use computer-controlled knives or lasers to cut materials, eliminating the need for physical dies. Cutting patterns can be changed instantly via software without requiring new tooling, allowing for high flexibility and precision.

Best For:

Short production runs

Prototyping and customized projects

Applications requiring frequent design changes

Integration with digital printing workflows

Advantages:

No physical die tooling needed, reducing setup time and costs

Quick pattern changes enable fast turnaround

High precision and ability to cut complex shapes

Ideal for personalized or small-batch production

Limitations:

Generally slower than rotary die cutting for very high volumes

Higher initial investment cost compared to manual or steel rule die cutters

May have material limitations depending on the laser or blade type used

Manual Die Cutting Machines

How It Works:

Manual die cutting machines are hand-operated devices that use physical dies to cut materials. The user applies pressure manually to stamp out shapes, often using a lever or crank mechanism.

Best For:

Hobbyists and craft enthusiasts

Small businesses with low production volume

Educational and training purposes

Prototyping and simple die cutting tasks

Advantages:

Affordable and portable

Easy to use with minimal setup

No electricity required

Great for learning and small-scale projects

Limitations:

Limited production capacity and speed

Not suitable for large or complex jobs

Requires physical dies for each design, which can add cost for multiple shapes

What are the Different Die Cutting Finishing Methods?

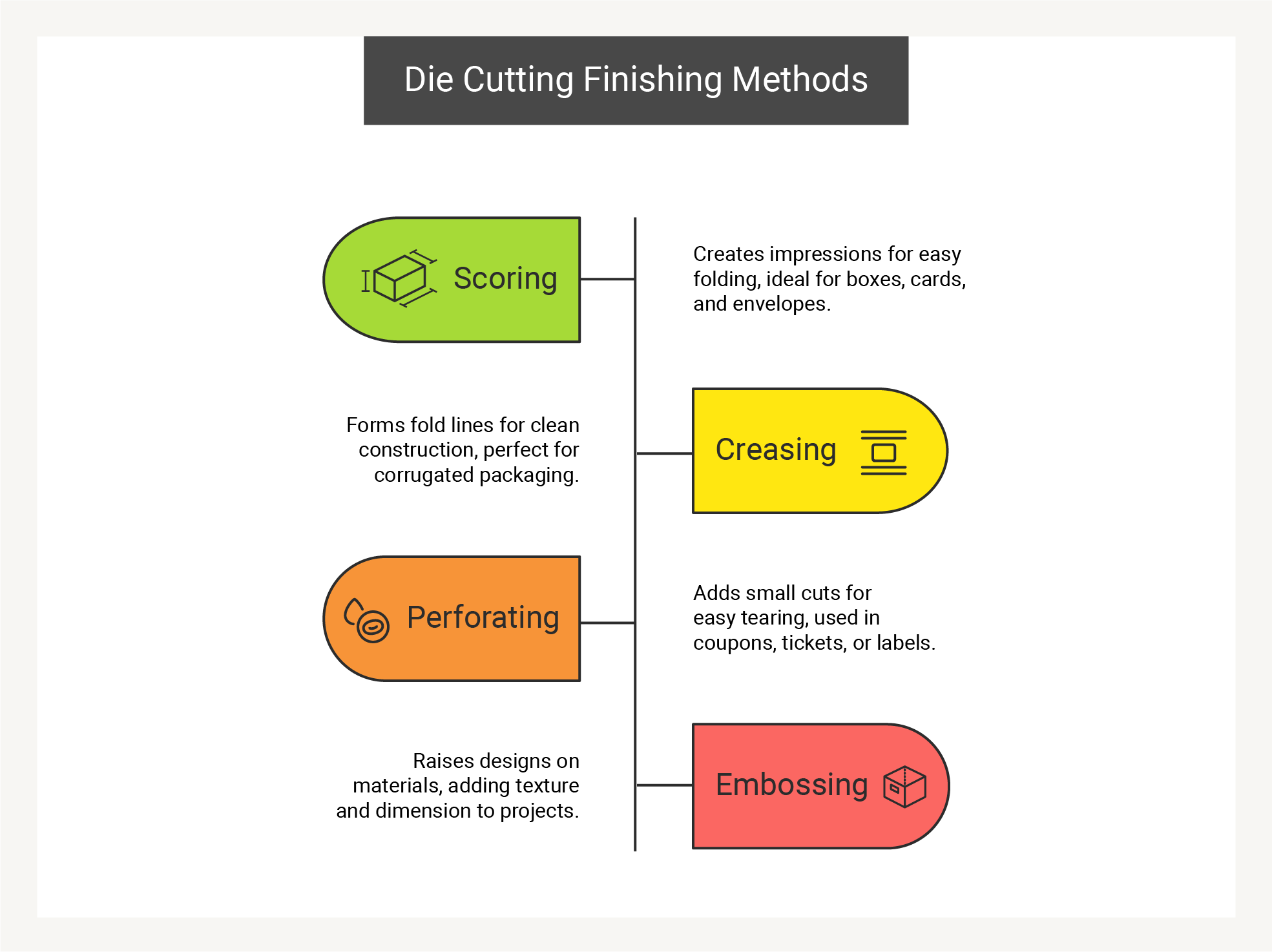

Scoring

Scoring involves creating an impression or partial cut on the material without slicing through it entirely. This technique is ideal for adding fold lines, making it easier to assemble items like boxes, cards, or envelopes.

Creasing

Creasing creates prominent fold lines that guide the material for easy construction. This is particularly useful for corrugated packaging, ensuring structural integrity and clean folds.

Different types of die cutting finishing methods.

Different types of die cutting finishing methods.

Perforating

Perforating leaves a series of small cuts along a specified line, allowing for easy tearing. It’s commonly used for creating tear-off coupons, tickets, or detachable labels.

Embossing

Many die cutting machines also double as a machine for embossing, adding another dimension to your projects. Embossing creates raised designs on paper and other materials, complementing the die cutting process beautifully.

Why is Die Cutting Crucial in Packaging?

Die cutting has become indispensable in the printing and packaging industry for several reasons:

Precision and Consistency: Die cut machine ensures every piece is identical, maintaining brand standards and enabling reliable assembly of packaging components.

Design Freedom: The technology allows designers to move beyond square boxes and rectangular labels, creating distinctive shapes that enhance brand recognition and product appeal.

Efficiency: Modern die cutting machines can process thousands of units per hour, dramatically reducing production time compared to manual cutting methods.

Material Optimization: Die cutting minimizes waste by efficiently arranging cutting patterns, an important consideration for sustainability and cost control.

How to Buy a Die Cutting Machine on Machine Dalal

Buying a die cutting machine on Machine Dalal is simple and efficient. Follow these steps:

Visit the Website: Go to machinedalal.com

Create an Account: Sign up if you don't already have an account.

Search for Machines: Use the search bar to find die cutting machines by keywords or brands.

Filter Results: Narrow your search using filters like type, brand, condition, and price range.

Review Listings: Click on listings to view specifications, images, and pricing details.

Contact the Seller: Reach out to the seller via email or phone for inquiries or negotiations.

Die cutting remains a vital technique in modern manufacturing, offering a range of methods suited to various materials and applications. Each type of die cutting has its unique advantages, making it essential to select the right method based on specific project needs. Understanding these techniques and their applications will help businesses and crafters optimize their production processes, enhance creativity, and reduce material waste.

FAQ

What materials can be cut with die cutting?

Die cutting can handle a wide range of materials including paper, cardboard, plastic, metal, fabric, foam, and more, depending on the method used.

How does laser die cutting differ from traditional die cutting?

Laser die cutting uses focused light for cutting opposed to physical dies. It's ideal for intricate designs and materials that may be too delicate for traditional methods.

What type of cutting dies does a rotary die cutting machine use?

A rotary die cutting press uses two types of cylindrical dies.

Solid dies are solid metal cylinders with permanently machined shapes.

Flexible/magnetic dies (mag-dies) use a magnetic cylinder wrapped with a thin metal sheet that has embossed cutting blades, allowing quick swaps for flexibility.

How do I choose between different die cutting methods?

Consider these factors when selecting a die cutting method:

Production volume requirements

Material type and thickness

Required precision and complexity

Budget constraints

Frequency of design changes

Available space for equipment

Machine Dalal is a global marketing and trading platform for print, packaging and converting industry. Its core mission is to facilitate direct, commission-free trading of print machinery, connecting buyers and sellers from around the world and fostering business relationships that often lead to repeat sales.

Machine Dalal is the global trading platform for the printing, packaging, and converting industry—designed to evolve with the needs of the market. We are continually innovating - from powerful search tools to integrated social media marketing, a growing newsletter audience, and our newly launched digital magazine, we are building a robust ecosystem to support print machinery sellers and buyers worldwide.

For a more personalized experience, download our mobile apps on Android and iOS.

To explore business opportunities or partnerships, feel free to get in touch with us.

The World of Print at your Fingertips

The Machine Dalal Mobile Apps

Download our Machine Dalal App Regular updates from our magazine with illustrations, innovations , commodities, history, media, art and a whole lot more from the magnificent world of Print.

Get the App

Login

Login