12/03/2025

Offset vs Digital Press

Understanding digital and offset printing processes, technology and applications in printing.

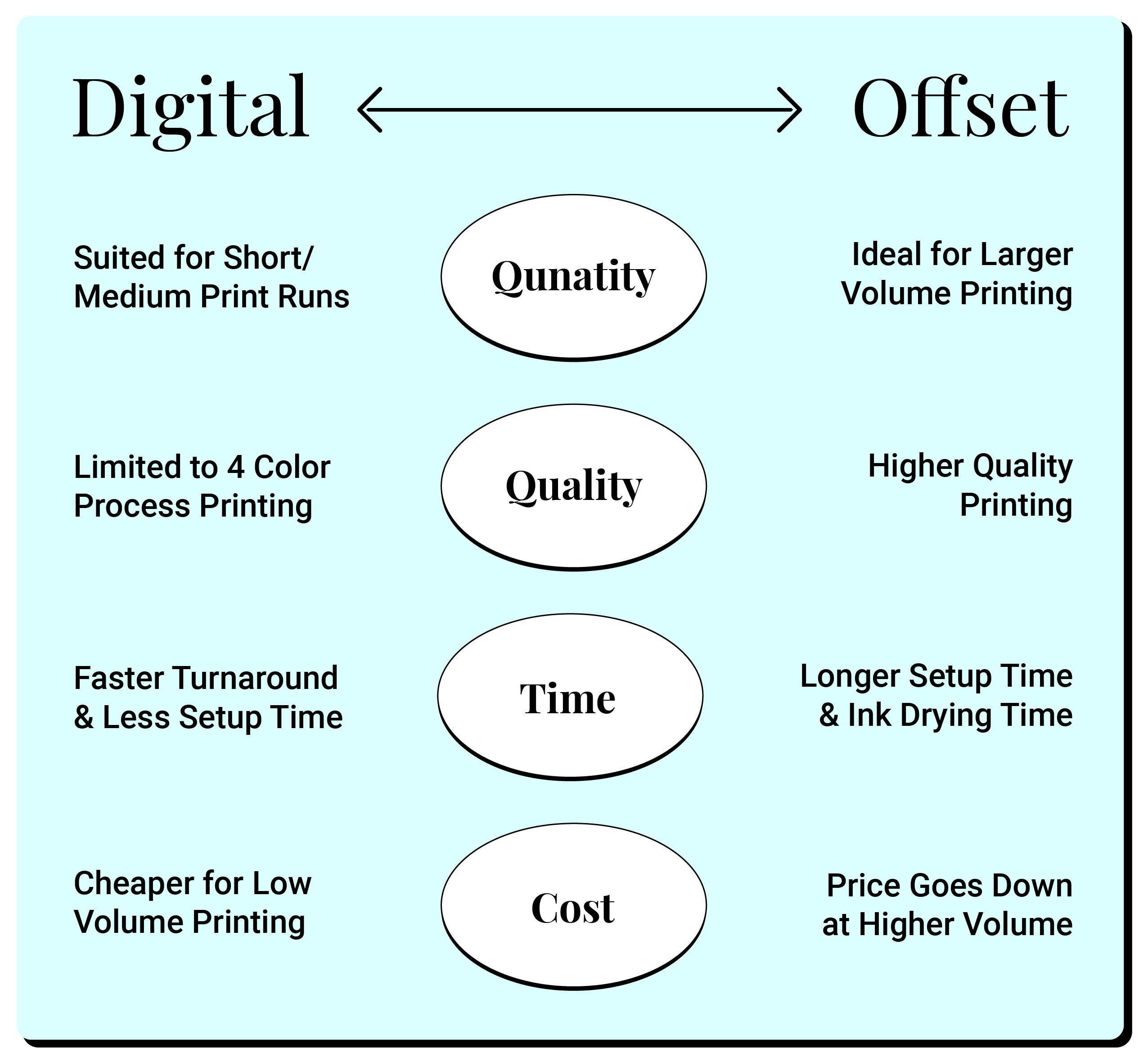

Digital and offset printing serve as complementary tools in the printing landscape, catering to different requirements and preferences. Offset printing, with its traditional roots, excels in producing large quantities with precise color accuracy, making it ideal for high-volume publications and branding materials. On the other hand, digital printing offers flexibility and speed, ideal for smaller quantities and personalized projects.

From the intricate details of plate creation in offset printing to the direct image transfer of digital printing, each method has its way of operating. This article delves into the inner workings of both digital and offset printing, providing a comprehensive overview of how they operate and the roles they play in contemporary printing.

The Evolution of Printing Technology

Like many industries reliant on machinery, printing is deeply intertwined with technology. From the ancient Chinese woodblocks to Gutenberg's revolutionary printing press, technological advancements have continually expanded the possibilities of printing. Today, modern printing relies primarily on two key technologies: offset printing and digital printing.

Professional printing services cater to clients with diverse printing needs, utilizing both digital and offset presses to deliver exceptional results. These services have expanded as more clients seek solutions that surpass the limitations of home printers. Professional printers excel in areas such as:

Quality: Achieving higher resolution and sharper images.

Size: Producing large-format prints, such as posters and banners.

Longevity: Utilizing inks and materials that resist fading and wear.

Color Accuracy: Precisely matching colors using advanced color management systems.

Material Variety: Printing on a wide range of materials, including cardstock, vinyl, and textiles.

Understanding the Basics

Offset Printing

Offset printing is a technique that uses large machines to transfer an image onto paper via a series of plates and rollers. Here’s a breakdown of the process:

Creating Print Plates: The process begins with creating print plates, which are customized for each job. These plates hold the image or text that will be printed.

Transfer to Intermediate Medium: The image is transferred from the print plates to a rubber blanket, which is the intermediate medium.

Final Transfer to Printing Surface: Finally, the image is transferred from the rubber blanket to the printing surface, ensuring a high-quality print.

Offset printing is renowned for its ability to produce sharp and clean images, making it ideal for large print runs where consistency and quality are paramount. However, this method is less flexible when it comes to small runs or customized designs due to the need for creating new plates for each change.

Digital Printing

Digital printing leverages technology similar to that found in computer printers but on a larger scale. Instead of a desktop machine, digital printers are standalone units designed for high-volume and wide-format printing. Digital printing offers several key features:

Digital File Creation: The process starts with a digital file, which can be easily altered or customized without the need for new plates.

Direct Printing: The image is printed directly onto the material. Unlike offset printing, where the image is transferred via an intermediate medium, digital printing applies the image directly to the surface.

Wiping Clean: One of the unique aspects of digital printing is that it wipes the image clean after every single impression. This feature allows for a lot more flexibility in printing, making it possible to produce small runs and a variety of designs quickly and efficiently.

Digital printing excels in producing vibrant, customizable prints on demand. This flexibility makes it ideal for personalized marketing materials, small batch projects, and designs that frequently change.

Key Operational Differences

Production Volume and Cost Efficiency

Small-Run Production

Digital printing shines for small quantities, offering consistent per-unit costs regardless of volume. With minimal setup requirements, digital printing enables cost-effective production of as few as one copy, making it ideal for:

Prototypes and proofs

Personalized marketing materials

Limited edition publications

On-demand printing needs

Large-Run Production

Offset printing requires significant setup but becomes increasingly cost-effective as quantities grow. The setup costs are distributed across more units, substantially lowering the per-piece price. Offset typically becomes economical at:

500-1,000 pieces for simple projects

1,000+ pieces for standard commercial printing

5,000+ pieces for maximum cost efficiency

Print Quality and Color Accuracy

Digital Print Quality

Modern digital presses produce excellent results with:

Resolution typically between 600-2400 dpi

Sharp text reproduction

Consistent color throughout the run

Vibrant photographic reproduction

However, digital printing may show slight banding in large color areas and lacks the absolute color precision of offset for brand-critical applications.

Offset Print Quality

Offset printing remains the gold standard for premium quality with:

Extremely fine detail reproduction

Smooth gradients and solid colors

Precise Pantone color matching

Superior rendering on uncoated papers

The human-operated nature of offset presses means there can be slight variations between print runs, though they remain remarkably consistent.

Turnaround Time

Digital Production Speed

Digital printing offers quick turnaround benefits:

No plate creation or complex setup

Immediate printing from approved files

Rapid completion of small to medium runs

Same-day or next-day delivery is possible for urgent projects

Offset Production Speed

Offset printing involves a longer preparation process:

Plate creation for each color

Press calibration and color matching

Test prints and adjustments

However, once running, offset presses operate at high speeds, making them efficient for large volumes despite longer setup times.

Sheet Size and Format

The physical dimensions of your project can also dictate which printing method is appropriate.

Digital Printing

Typically limited to smaller sheet sizes

Generally between 19-29 inches depending on the equipment

For larger formats, wide-format digital printing is available but has its limitations

Offset Printing

Can accommodate larger sheet sizes

Typically from 29-40 inches

Better suited for large-format projects that would be impossible or impractical with standard digital printing

Material Versatility

Digital Material Options

Digital printing technology has expanded to accommodate:

Standard papers from lightweight to moderately heavy stocks

Specialty papers including textured options

Synthetic materials like vinyl and polyester

Rigid substrates with flatbed digital printers

Material limitations exist primarily in very heavy stocks and some specialty finishes.

Offset Material Options

Offset printing excels with a wide range of materials:

Virtually all paper weights and finishes

Specialty stocks including metallic papers

Unique textures and finishes

Absorbent materials that digital inks might oversaturate

The mechanical pressure of offset printing also allows for special effects like embossing when combined with additional processes.

Variable Data Capabilities

Digital Personalization

One of digital printing's greatest strengths is variable data printing:

Each piece can contain unique text, images, or codes

Database-driven personalization for targeted marketing

Sequential numbering or coding

Version control for different audience

Offset

Traditional offset printing produces identical pieces throughout the run. Variable information requires:

Additional digital imprinting after offset printing

Pre-printed shells with variable data added later

Multiple plate changes for version changes, which is costly

Final Word

Digital and offset presses each play a crucial role in the printing industry, offering distinct capabilities. Digital presses allow for quick turnaround times and the ability to print personalized materials, making them ideal for projects that require flexibility and speed. They excel in producing small to medium quantities efficiently, enabling businesses to respond rapidly to market demands.

FAQs

What is the main difference between offset and digital printing?

Offset printing is better for large quantities and precise color matching using Pantone inks. Digital printing is more cost-effective for smaller quantities and allows for variable data printing.

What is the fastest possible turnaround for digital printing?

Many print providers offer same-day service for simple digital printing projects submitted with print-ready files early in the day. Standard turnaround is typically 1-2 business days for straightforward projects.

Is paper quality different between digital and offset printing?

Both technologies can use high-quality papers, but they interact differently with the substrate. Digital printing sits more on the surface of the paper, while offset inks are absorbed more deeply. This difference is most noticeable on uncoated stocks, where offset often produces richer results.

What types of materials can be printed on with digital printing?

Digital printing can handle various materials including paper, plastic, vinyl, and canvas.

Is it possible to combine digital and offset printing in one project?

Yes, hybrid approaches are increasingly common. For example, a catalog might have its cover and standard pages printed offset for quality and economy, while incorporating digitally printed personalized inserts or variable coupons.

We at Machine Dalal have a wide selection of print, packaging, and converting machines listed with us. Industry sellers from all over the world list their print equipment with us to reach interested buyers who regularly visit our platform to find equipment that matches their needs.

At Machine Dalal, we connect the supply and purchasing needs of the print industry.

Machine Dalal is the global trading platform for the printing, packaging, and converting industry—designed to evolve with the needs of the market. We are continually innovating - from powerful search tools to integrated social media marketing, a growing newsletter audience, and our newly launched digital magazine, we are building a robust ecosystem to support print machinery sellers and buyers worldwide.

For a more personalized experience, download our mobile apps on Android and iOS.

To explore business opportunities or partnerships, feel free to get in touch with us.

The World of Print at your Fingertips

The Machine Dalal Mobile Apps

Download our Machine Dalal App Regular updates from our magazine with illustrations, innovations , commodities, history, media, art and a whole lot more from the magnificent world of Print.

Get the App

Login

Login