10/04/2025

How to Buy the Right Die-Cutting Machine

A comprehensive guide to help you evaluate features, compare options, and buy the right die cutting machine.

Die cutting machines blend precision engineering with creative possibilities. These tools turn flat materials into custom shapes using cutting dies or computerized blades. When you buy die cutting machine products, you're investing in technology that can transform your production capabilities.

From the meticulous craftsperson creating handmade cards with a craft cutting machine to large manufacturing operations producing thousands of packaging units daily, die cut machines have become essential equipment in the packaging industry. The decision to buy die cutting machine models should be based on your specific requirements.

Whether you're upgrading your production line or starting a new venture, selecting the right die cutting machine is crucial. This guide explores key considerations to help you buy die cutting machine options that perfectly match your needs, covering types, features, and where to find them.

What are the types of Die Cut Machines?

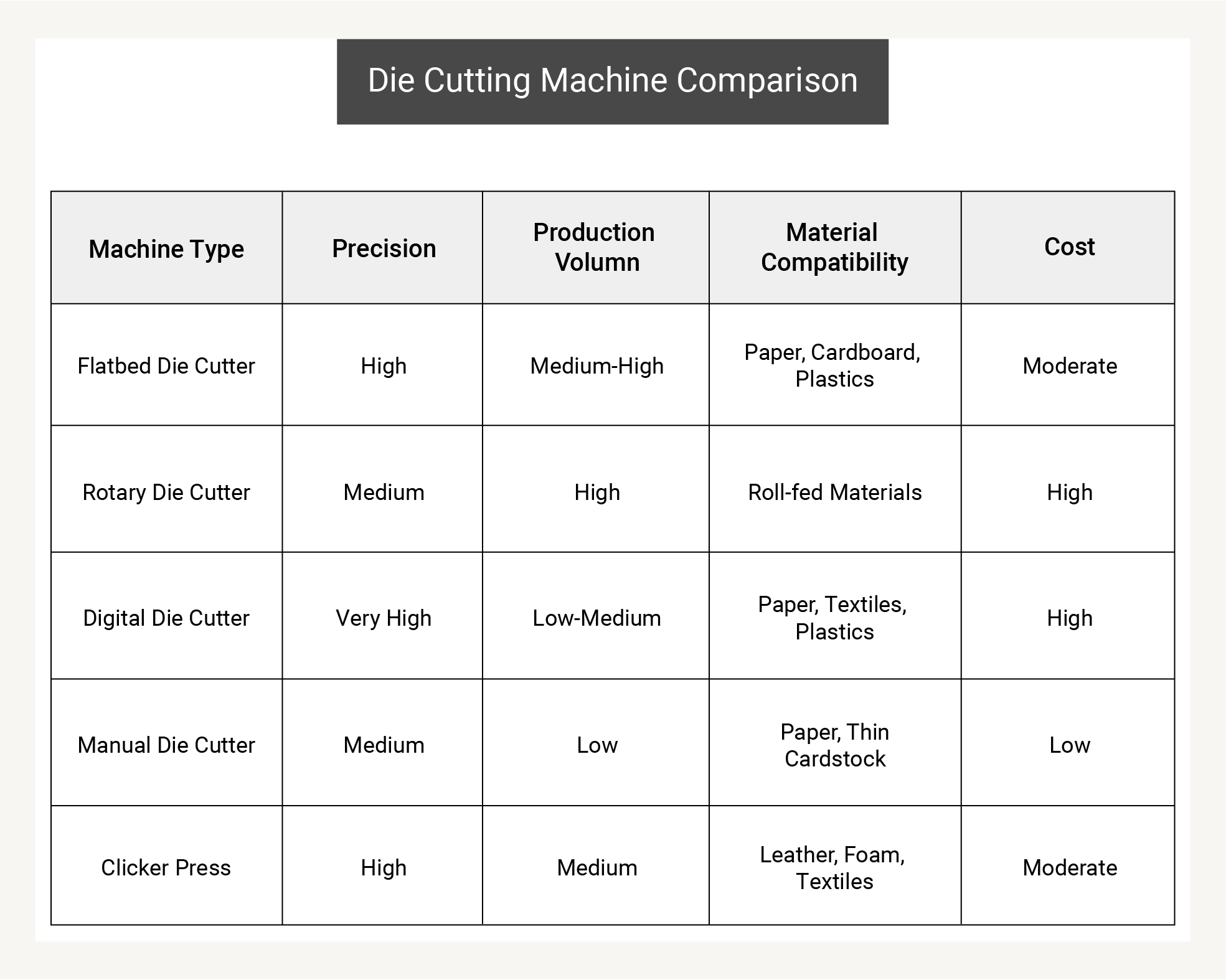

Before you buy die cutting machine equipment, understand these different varieties, each designed for specific applications and production volumes:

1. Flatbed Die Cutters

These machines use a flat die to cut materials laid on a flat surface. When you buy die cutting machine flatbed models, you're getting equipment known for precision and versatility. They can handle a wide range of materials and are commonly used for medium to high-volume production runs. They operate by pressing the die down onto the material with significant force, creating clean, precise cuts. Industrial die cutting machines often use this mechanism for large-scale production.

You can view flatbed die cutting machine options that offer precision cutting for various materials.

2. Rotary Die Cutters

Rotary die cutting machine manufacturers design systems that use cylindrical dies mounted on rotating cylinders. As materials pass between these cylinders, they're cut into the desired shapes. These machines excel at high-speed, continuous production and are ideal for processing roll-fed materials. A rotary die cutter is the workhorse of the packaging industry, capable of processing thousands of units per hour. Rotary die cutting machines are particularly valuable for businesses with high-volume needs. The rotary die cutting paper cutter machine combines both cutting functionalities for versatile applications.

3. Digital Die Cutters

The newest evolution in die cutting technology, digital die cutting machines use computer-controlled knives or lasers instead of physical dies. The digital die cutting machine can change cutting patterns instantly without tooling changes, making them perfect for short runs, prototyping, and customized projects. These machines represent the convergence of traditional die cutting with digital printing technology.

4. Manual Die Cutting Machines

These are smaller, portable machines typically used in craft settings, small businesses, or for prototyping. While limited in production capacity, they offer an affordable cutting machine entry point into die cutting technology. A manual die cutting machine is perfect for hobbyists and small businesses with limited production needs. Die cut manual machines are also excellent for educational purposes and training when learning how to use a die cutting machine.

Check out a used manual die cutting machine that is located in the United Kingdom.

5. Clicker Presses

Popular in the leather, textile, and die cut fabric industries, clicker presses use a swinging arm with hydraulic or pneumatic pressure to push dies through materials. The die press machine is valued for its combination of force and precision when cutting thicker materials. This type is especially useful for fabric cutter projects. The fabric cutting machine capability makes it versatile across multiple industries.

The die cutting machines come in different formats for different needs, defined by their sheet size compatibility, where you can explore options ranging from small sheet sizes to standard sheet sizes to large format die cutting machine options to best fit your projects.

Before diving into the specifics of choosing the right machine, it's crucial to understand the fundamentals. To get a solid foundation, refer to our article on everything you need to know before you buy a die-cutting machine.

How to Choose a Die Cutting Machine?

There are some key factors to consider before you buy die cutting machine equipment.

Cutting Capabilities and Materials

Cutting force (measured in grams or kilograms) directly affects what materials you can cut:

Light Force: Paper, vinyl, thin cardstock

Medium Force: Cardstock, craft vinyl, thin fabrics

Heavy Force: Leather, balsa wood, chipboard, thick fabrics

Industrial Force: Thick materials, industrial substrates

Material Compatibility

Consider what materials you'll be working with:

Paper Crafts: Most die paper cut machine options handle paper and cardstock well

Fabric Projects: Look for fabric cutting machine specific blades and feeding mechanisms

Mixed Media: More versatile machines offer adjustable pressure settings

Specialty Materials: Some machines specifically support materials like wood, leather, or metal sheets

Cutting Width and Depth

The machine's dimensions limit what you can create:

Small Format: Cards, small crafts, scrapbooking elements

Medium Format: Standard crafting sheets, vinyl projects

Large Format: Signage, large designs, production work

Physical Considerations

- Storage Space:Will you need to put it away between uses?

Workspace Footprint: Is there enough space around the machine for material handling?

Portability:Will you need to move the die cutting machine regularly?

Maintenance Requirements

Cleaning Access: Can cutting areas be easily cleaned?

Replaceable Parts: Availability and cost of wear items

Service Network: Professional repair options

Dual Functionality

Many modern die cutting machines for crafting offer multiple functions:

Cutting and Embossing: Creates dimensional designs with a machine for embossing

Cutting and Drawing: Adds details to cut pieces

Cutting and Scoring: Creates fold lines for 3D items

Multi-Tool Capability: Simultaneous operations

Automation Features

Features that enhance productivity:

Auto-Feed Systems: Continuous material feeding

Job Memory: Stores settings for repeat projects

Tool Detection:Automatically identifies installed tools

Material Presets:Optimized settings for common materials

Choosing the right manufacturer is just as important as selecting the right machine. See our curated list of thetop 10 die-cutting machine manufacturers to guide your decision."

Where to Buy Die Cutting Machine?

Several reliable sources offer quality equipment:

Industry Suppliers:Specialized equipment dealers provide expertise alongside their machines

Die Cut Manufacturer Direct: Major die cutting machine makers sell directly to end-users

Equipment Expos: Trade shows where multiple manufacturers showcase their products

Online Marketplaces: Industrial equipment platforms featuring new and used machines

Equipment Brokers:Specialists who can source specific machines based on requirements

Authorized Die Cutting Dealer: Local representatives of major manufacturers

How to Buy Die Cutting Machine on Machine Dalal ?

Buying a die cutting machine on Machine Dalal is simple and efficient. Follow these steps:

Visit the Website: Go to machinedalal.com

Create an Account: Sign up if you don't already have an account

Search for Machines: Use the search bar to find die cutting machines by keywords or brands

Filter Results: Narrow your search using filters like type, brand, condition, and price range

Review Listings: Click on listings to view specifications, images, and pricing details

Contact the Seller: Reach out to the seller via email or phone for inquiries or negotiations

Buying a die cutting machine on Machine Dalal is simple and efficient. View this used die cutting machine as an example of how easy it is to connect to the seller and check out the machinery details through the platform.

FAQs

What's the difference between a rotary die cutter and flatbed die cutter?

A rotary die cutter uses cylindrical dies on rotating cylinders for continuous operation, ideal for high-volume work. Flatbed machines use a platen press design for precise, controlled cutting, often preferred for complex or registration-critical applications. The guillotine cutter commercial die cutter combines both functionalities for versatile applications.

Where can I find a used die cutting machine for?

For buyers looking to buy die cutting machine, consider craft stores, online marketplaces like Machine Dalal, Amazon, or second-hand equipment sites. Many brands offer basic models that provide essential functionality without the higher price tag of professional models.

Who should consider investing in an industrial die cutting machine?

Businesses with high production volumes, manufacturing facilities, and commercial print shops would benefit most from an industrial die cutting machine. These robust systems offer faster production speeds, greater durability, and the ability to handle thicker materials.

How do die cutting dies for die cutting machines affect overall performance?

The quality of die cutting dies for die cutting machines significantly impacts cut precision, machine longevity, and material waste. Premium dies offer cleaner cuts, longer lifespan, and better detail reproduction, making them worth the investment for professional applications.

Do I need different blades for different materials?

Yes, most digital die cutting machine options require specific blades for different materials. For example, rotary blades work better for fabrics in a fabric cutting machine, while deep-cut blades are necessary for thicker materials like chipboard or balsa wood. Using the proper blade for each material ensures clean cuts and extends blade life.

Can I create my own designs or am I limited to purchasing premade designs?

With digital die cutting machines, you can create custom designs using the manufacturer's software or other design programs like Adobe Illustrator, Inkscape, or CorelDRAW. While many manufacturers offer purchasable designs, most modern machines allow you to import SVG files and other common formats created in third-party software.

Is it worth paying more for a well-known die cut manufacturer?

Established brands typically offer better customer support, longer warranties, wider availability of accessories, and more robust online communities for troubleshooting and inspiration. The resale value also tends to be higher for recognized brands. For occasional users, affordable cutting machine options may be sufficient, but frequent users often find that quality brands deliver better long-term value.

What Types of Materials Can Be Cut with a Die Cutting Machine?

Die cutting machines handle a variety of materials, including:

Paper: Coated paper, kraft paper, and cardboard.

Film: PE, PET, and BOPP films.

Labels: Adhesive labels and vinyl stickers.

Others: Foam, rubber, and thin metals.

By carefully evaluating these factors against your specific needs, you can buy die cutting machine options that will provide years of creative satisfaction and productivity. Remember that the best machine for you is one that matches your typical projects, materials, and usage patterns—not necessarily the most expensive or feature-rich option on the market.

Machine Dalal is a global trading platform for buyers and sellers of print, packaging and converting equipment to connect directly and trade their machinery.

Machine Dalal is the global trading platform for the printing, packaging, and converting industry—designed to evolve with the needs of the market. We are continually innovating - from powerful search tools to integrated social media marketing, a growing newsletter audience, and our newly launched digital magazine, we are building a robust ecosystem to support print machinery sellers and buyers worldwide.

For a more personalized experience, download our mobile apps on Android and iOS.

To explore business opportunities or partnerships, feel free to get in touch with us.

The World of Print at your Fingertips

The Machine Dalal Mobile Apps

Download our Machine Dalal App Regular updates from our magazine with illustrations, innovations , commodities, history, media, art and a whole lot more from the magnificent world of Print.

Get the App

Login

Login