10/03/2025

How Automation is Reshaping the Packaging Industry

From reducing material waste to improving sustainability, automation is driving a new era of smart, data-driven packaging solutions.

In October 2023, Amazon unveiled its "first-of-its-kind" automated packing technology at its UK and German fulfillment centers. This innovative system uses in-built sensors to cut specially developed paper packaging according to the size of the item being delivered, reducing waste and improving efficiency. This technological leap is just one example of how the innovation in automation is transforming the packaging industry.

Market Growth and Trends

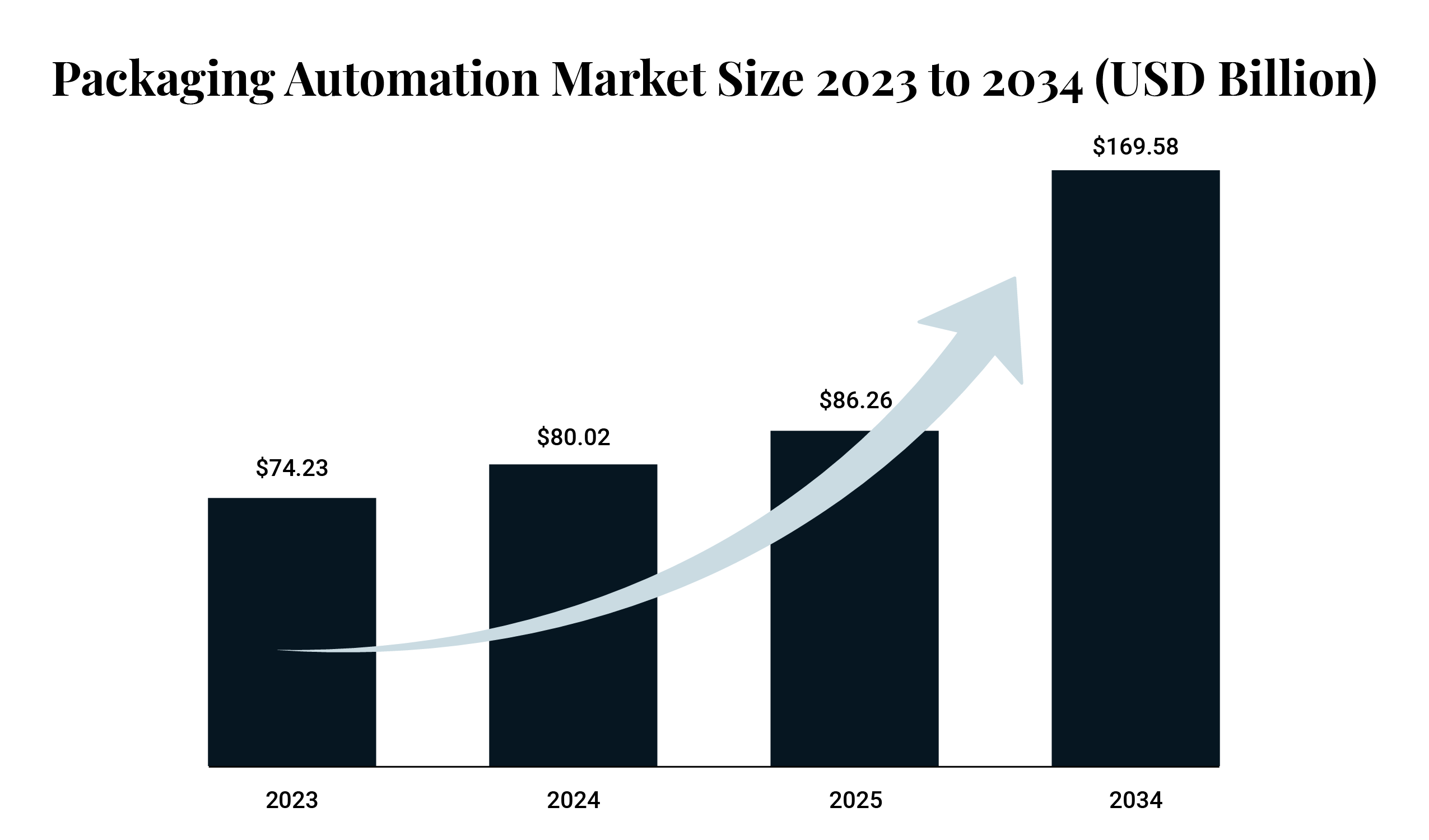

As the global packaging automation market size is estimated at USD 80.02 billion in 2024 and is anticipated to reach around USD 169.58 billion by 2034, expanding at a CAGR of 7.80% from 2024 to 2034, businesses are adopting automation to enhance efficiency, reduce costs, and support sustainability efforts.

Regional Growth

As per a report, the market growth for automation in packaging varies significantly across different regions, reflecting the pace of technological adoption and industrial advancements:

North America leads the packaging automation market with 39% share.

Asia-Pacific follows closely with 30% market share.

Europe holds a 24% market share.

Latin America contributes 4% to the market.

Middle East and Africa have the smallest share at 3%.

Key Drivers

E-commerce Growth: The rise of online shopping has increased demand for fast, efficient packaging solutions.

Sustainability: Consumers are pushing for eco-friendly packaging, driving the adoption of automation to optimize material usage.

Regulatory Compliance: Stringent food safety regulations require precision and hygiene in packaging processes.

How Automation is Transforming Packaging Processes

Automation is reshaping the packaging industry in several critical ways:

Enhanced Efficiency

Robotic arms handle repetitive tasks like sorting and palletizing at speeds far beyond human capability. Predictive maintenance systems minimize downtime by identifying potential issues before they occur.

Cost Reduction

While initial investments in automation are high, they result in long-term savings:

Reduced labor costs as machines take over repetitive tasks.

Consistent quality reduces product recalls and waste.

Sustainability

Automated systems optimize material usage, reducing waste and supporting the use of biodegradable materials:

Companies like Unilever have invested in automated recycling systems to process eco-friendly packaging efficiently.

Improved Quality Control

AI-powered vision systems ensure every package meets strict quality standards:

Automated inspections detect defects in real-time, improving product reliability.

Key Automation Technologies in Packaging

The packaging industry is undergoing a significant transformation, driven by advanced automation technologies that enhance efficiency, precision, and adaptability. Below are the key technologies reshaping the sector:

Robotics

Although robots have been in use in factories for decades, the arrival of smarter, more compact robotic solutions speed-up packaging systems, add flexibility and reduce mistakes caused by human error.

Pick-and-Place Operations: Robots equipped with advanced sensors and grippers can handle delicate or irregularly shaped items with high accuracy, making them ideal for diverse packaging needs.

Palletizing:Robotic palletizers efficiently stack products onto pallets, accommodating various product sizes and configurations while reducing labor costs.

Case Packing: Robots automate case packing processes, ensuring consistent filling and minimizing manual intervention.

Artificial Intelligence (AI) and Machine Learning (ML)

AI and ML are revolutionizing packaging by enabling intelligent decision-making and process optimization:

Predictive Maintenance: AI algorithms analyze equipment data to predict potential failures, reducing downtime and extending machinery lifespan.

Quality Control: AI-powered machine vision systems inspect products for defects, ensuring high-quality standards with minimal errors.

Dynamic Adjustments: AI systems make real-time adjustments to accommodate variations in product size, shape, or weight, optimizing efficiency without manual reconfiguration.

Internet of Things (IoT)

IoT connects packaging machinery to the internet, enabling real-time monitoring and enhanced control:

Real-Time Data Monitoring: IoT sensors track machine performance metrics like speed, temperature, and pressure, allowing operators to optimize operations proactively.

Remote Access: IoT connectivity enables remote troubleshooting and adjustments, streamlining the management of multiple packaging lines or facilities.

Supply Chain Integration: IoT enhances visibility and coordination across supply chains by integrating packaging systems with broader logistics networks.

Smart Packaging

Smart packaging incorporates advanced technologies like QR codes, NFC (Near Field Communication), and RFID (Radio Frequency Identification) to offer added functionality:

Consumer Engagement: Interactive features such as QR codes allow customers to access product information or promotions via their mobile devices.

Traceability: RFID and NFC improve product tracking across the supply chain, reducing counterfeiting risks.

Condition Monitoring: Sensors in smart packaging monitor environmental factors like temperature and humidity, ensuring optimal storage and transport conditions.

Impact of Automation on Sustainability

As sustainability becomes increasingly important in the packaging industry, automation is playing a pivotal role in achieving environmental objectives. Here are the keyways automation contributes to sustainability:

Reduced Material Waste

Automated systems significantly reduce material waste by ensuring precise operations:

Accurate Measurements: Automated cutting, filling, and sealing processes minimize errors, leading to more efficient use of packaging materials.

Optimized Resource Use: By reducing waste, automation helps conserve resources and lower production costs.

Energy Efficiency

Modern automated packaging systems are engineered to be energy-efficient:

Advanced Servo-Driven Systems: These systems consume less energy compared to traditional pneumatic systems, resulting in reduced energy consumption and a lower environmental footprint.

Sustainable Operations: Energy-efficient automation supports companies in meeting their sustainability targets while maintaining operational efficiency.

UK consumer goods conglomerate Unilever recently announced that, together with Chinese e-commerce giant Alibaba, it has created recycling machines that use artificial AI to automatically identify and sort waste plastic packaging for recycling in China, as well as optimise designs of some of its products sold in plastic bottles to make them more sustainable.

Recycling and Reuse

Automation supports the development and processing of recyclable and reusable packaging materials:

AI-Powered Sorting Systems: Equipped with machine vision, these systems accurately separate different materials, enhancing recycling efficiency and improving recycling rates.

Circular Economy Initiatives: By facilitating effective recycling processes, automation helps promote a circular economy, where materials are kept in use for as long as possible.

Future Trends in Packaging Automation

The packaging industry is set to undergo significant advancements, driven by technological innovation and evolving consumer demands. Below are the key trends shaping the future of packaging automation:

Collaborative Robots (Cobots)

Cobots are designed to work alongside human operators, enhancing both productivity and workplace safety. Their ease of use, adaptability, and ability to handle repetitive tasks make them increasingly popular in packaging operations.

Cobots are expected to become more prevalent due to their ability to improve efficiency while maintaining flexibility in handling diverse packaging requirements.

Blockchain Technology

Blockchain is poised to revolutionize supply chain management by ensuring secure and transparent product tracking. In the packaging sector, blockchain can:

Verify product authenticity.

Enhance traceability across the supply chain.

Ensure compliance with regulatory requirements.

This technology is particularly valuable for industries like food, pharmaceuticals, and luxury goods, where transparency and trust are critical.

Advanced Materials and Processes

Innovations in materials science and manufacturing processes are set to redefine packaging automation:

Biodegradable and Sustainable Materials: The use of eco-friendly materials addresses growing consumer demand for sustainability.

3D Printing: This technology enables rapid prototyping and customization of packaging components, reducing production time and costs.

Final Word

The packaging industry stands at the crossroads of innovation and sustainability, with automation technologies driving unprecedented transformation. From AI-powered quality control to IoT-enabled smart packaging, these advancements are not just improving efficiency and reducing costs but also addressing crucial environmental concerns.

As collaborative robots become more prevalent and technologies like blockchain enhance supply chain transparency, we can expect the $75 billion packaging automation market to continue its robust growth toward $155 billion by 2033. The future of packaging is automated, intelligent, and sustainable positioning the industry to meet the challenges of tomorrow's global marketplace.

FAQs

What is packaging automation?

Packaging automation uses advanced technologies like robotics and AI to streamline processes such as filling, sealing, labeling, and palletizing while reducing human error.

What is driving the growth of automation in the packaging industry?

Key factors include the rise of e-commerce, increasing consumer demand for sustainable packaging, and stringent regulatory compliance requirements for food safety.

What are the long-term cost benefits of implementing automation in packaging?

While initial investments can be high, automation leads to long-term savings through reduced labor costs, consistent product quality that lowers waste, and minimized product recalls.

How do AI and machine learning improve packaging operations?

AI and ML optimize processes through predictive maintenance, quality control via machine vision, and dynamic adjustments based on product variations.

What is the role of IoT in packaging automation?

IoT connects packaging machinery to the internet, enabling real-time monitoring, remote access for troubleshooting, and better integration with supply chain management systems.

What are some emerging trends in packaging automation?

Emerging trends include the increasing use of collaborative robots (cobots), the application of blockchain technology for supply chain transparency, and the adoption of advanced, sustainable materials.

We at Machine Dalal have a wide selection of print, packaging and converting machines listed with us. Industry sellers from all over the world list their print equipment with us to reach interested buyers who regularly visit our platform to find equipment that matches their needs.

Machine Dalal is the global trading platform for the printing, packaging, and converting industry—designed to evolve with the needs of the market. We are continually innovating - from powerful search tools to integrated social media marketing, a growing newsletter audience, and our newly launched digital magazine, we are building a robust ecosystem to support print machinery sellers and buyers worldwide.

For a more personalized experience, download our mobile apps on Android and iOS.

To explore business opportunities or partnerships, feel free to get in touch with us.

The World of Print at your Fingertips

The Machine Dalal Mobile Apps

Download our Machine Dalal App Regular updates from our magazine with illustrations, innovations , commodities, history, media, art and a whole lot more from the magnificent world of Print.

Get the App

Login

Login