04/04/2025

Everything You Need to Know Before You Buy a Die Cutting Machine

A comprehensive overview of die cutting machines, their application, technological advancements and role in the packaging industry.

Die cutting has its origins in letterpress printing, and it evolved to become a more specific manufacturing process. The die cut machine process in packaging utilizes a die to cut materials into an array of different shapes, designs, and patterns. A die cutting machine is a piece of industrial or commercial manufacturing equipment used to cut materials into specific shapes. Whether you're looking for a die paper cutting machine for your business or exploring options for a die cut machine for personal use, understanding the basics is essential. These versatile machines can cut everything from paper and fabric to rubber, foil, foam, and even sheet metal.

What is a Die Cutting Machine?

A die cutting machine is a specialized piece of equipment that uses sharp steel blades formed into specific shapes (called dies) to cut through various materials with precision and consistency. Think of it as an industrial cookie cutter—except instead of cookies, these machines can cut through virtually any flat material to create custom shapes for packaging, labels, promotional materials, and more.

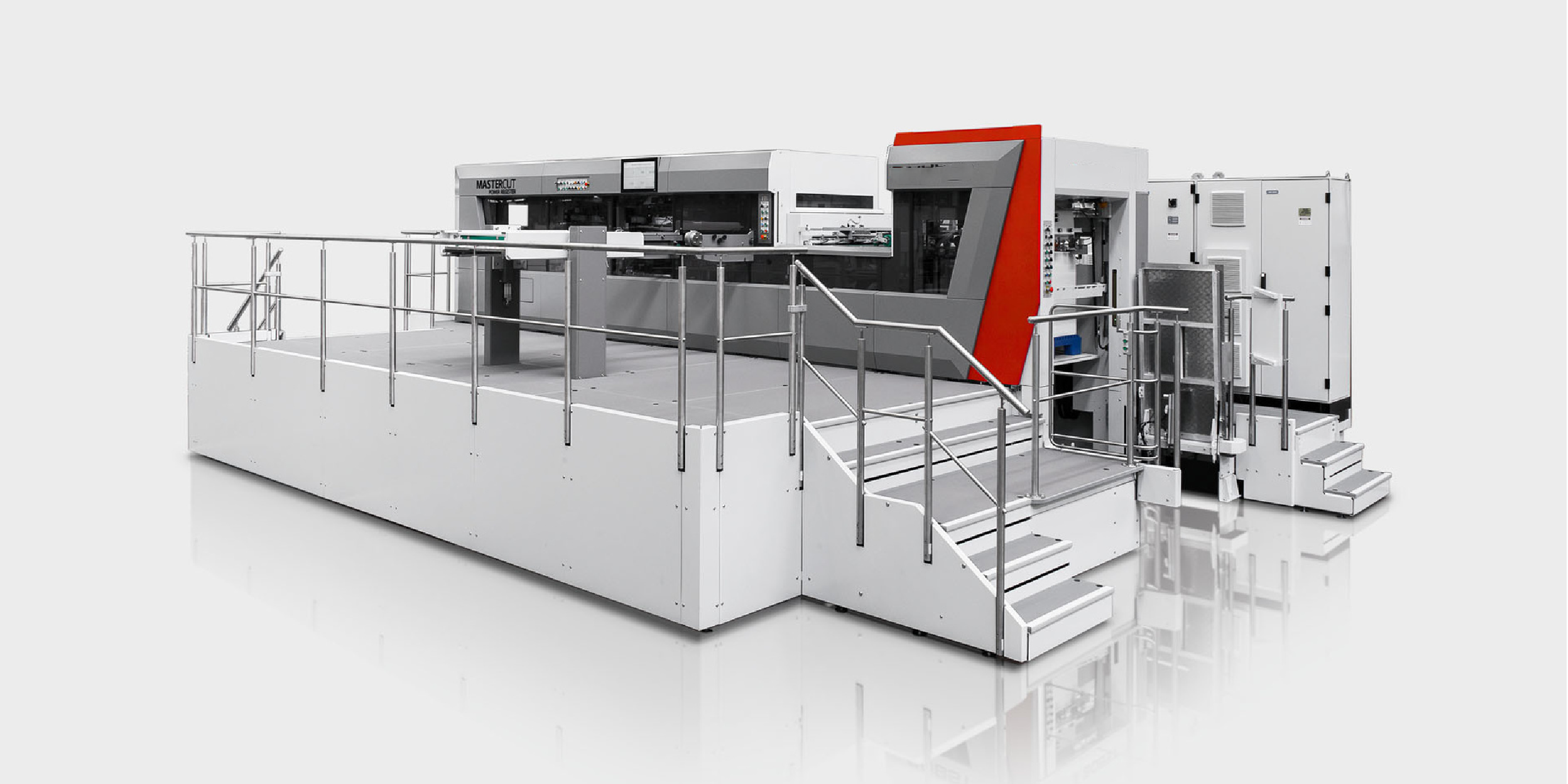

Modern die cutting machines range from simple manual die cutting machines used in small craft businesses to sophisticated computer-controlled systems employed in large manufacturing facilities. These die cut machines have revolutionized the printing and packaging industry by enabling mass production of intricately cut materials with consistent quality and reduced labor costs. Check out this new die cutting machine that exemplifies modern precision technology. Along with it you can also view this other automatic die cutting machine that is consistent in quality and versatile when it comes to materials.

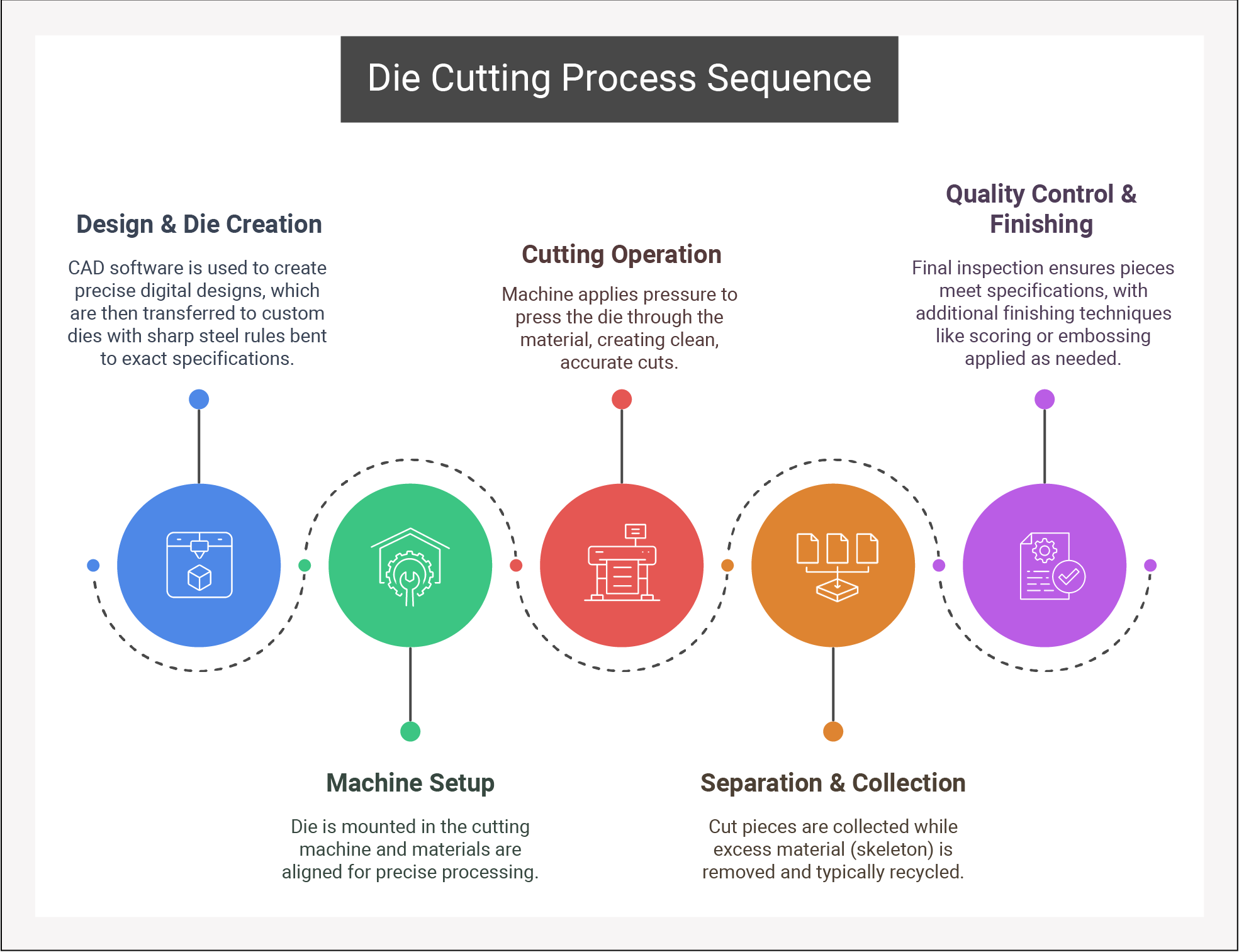

What are the steps in die cutting process?

Understanding the die cutting process helps appreciate the technology's capabilities:

Design Creation: The process begins with designing the shape to be cut. This is typically done using CAD (Computer-Aided Design) software.

Die Fabrication: Custom dies are manufactured according to the design specifications. These dies are typically made from hardened steel with razor-sharp edges formed to the exact shape needed.

3. Machine Setup: The die is mounted securely in the die cutting machine, and the material to be cut is positioned properly.

4. Cutting Operation: Depending on the machine type, either the die descends onto the material (flatbed), the material passes between rotating dies (rotary), or computer-controlled knives follow the programmed path (digital).

Collection and Separation: After cutting, the finished pieces are collected, and waste material is removed and typically recycled.

Quality Control:Finished pieces are inspected to ensure they meet specifications for size, shape, and edge quality.

At Machine Dalal we encourage sellers to upload quality images of their machines to make it easy for buyers to make informed decisions. Here is a die-cutting machine you can view in action in one of those videos uploaded by seller.

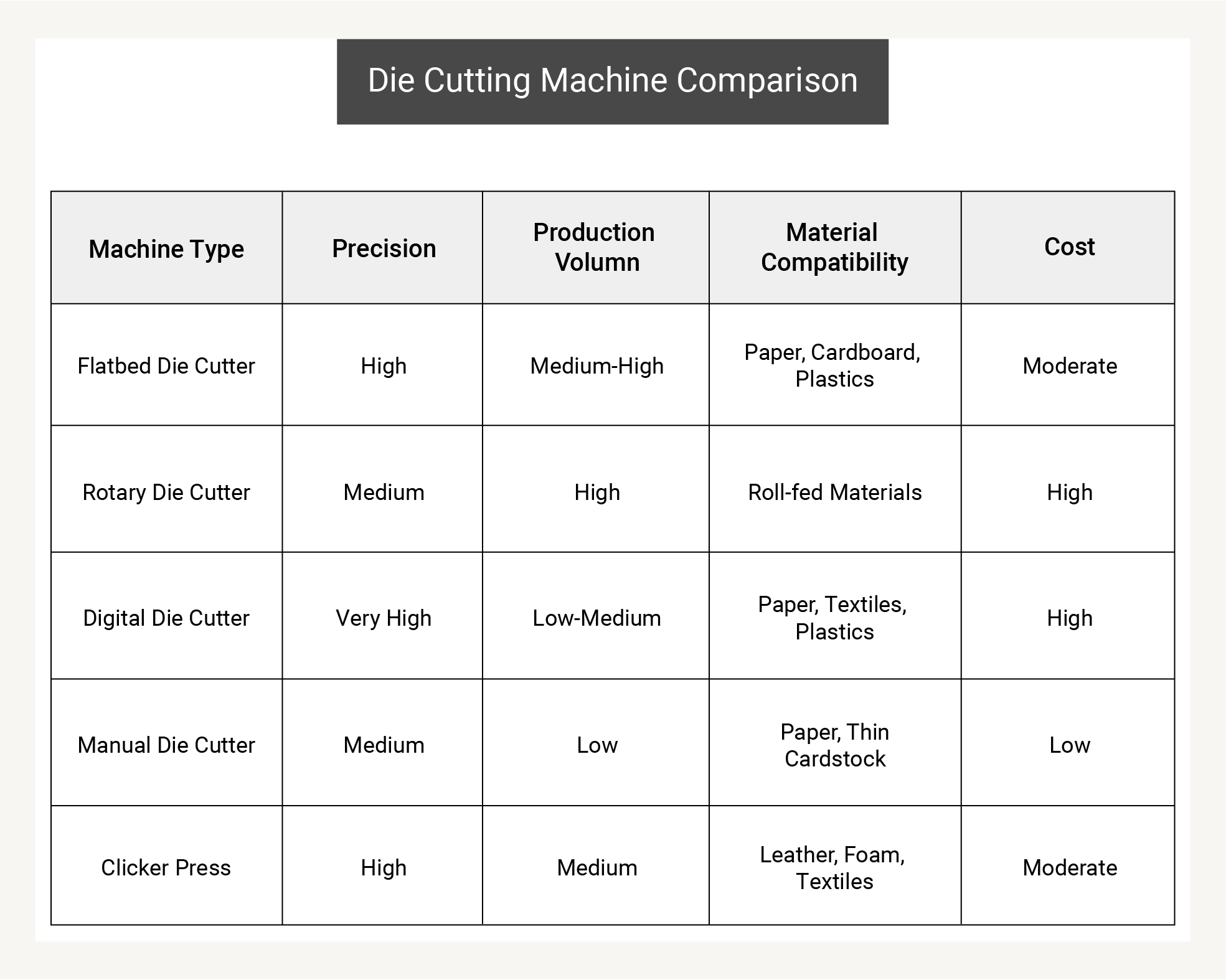

What are the types of Die Cut Machines?

Die cutting machines come in various forms, each designed for specific applications and production volumes:

Flatbed Die Cutters

These machines use a flat die to cut materials laid on a flat surface. Flatbed die-cutters are known for their precision and versatility. They can handle a wide range of materials and are commonly used for medium to high-volume production runs. They operate by pressing the die down onto the material with significant force, creating clean, precise cuts. Industrial die cutting machines often use this mechanism for large-scale production.

You can view flatbed die cutting machine that offer precision cutting for various materials.

Rotary Die Cutters

Rotary die cutting machine manufacturers design systems that use cylindrical dies mounted on rotating cylinders. As materials pass between these cylinders, they're cut into the desired shapes. These machines excel at high-speed, continuous production and are ideal for processing roll-fed materials. A rotary die cutter is the workhorse of the packaging industry, capable of processing thousands of units per hour. Rotary die cutting machines are particularly valuable for businesses with high-volume needs.

Digital Die Cutters

The newest evolution in die cutting technology, digital die cutting machines use computer-controlled knives or lasers instead of physical dies. They can change cutting patterns instantly without tooling changes, making them perfect for short runs, prototyping, and customized projects. These machines represent the convergence of traditional die cutting with digital printing technology.

Manual Die Cutting Machines

These are smaller, portable machines typically used in craft settings, small businesses, or for prototyping. While limited in production capacity, they offer an affordable entry point into die cutting technology. A manual die cutting machine is perfect for hobbyists and small businesses with limited production needs. Die cut manual machines are also excellent for educational purposes and training.

Checkout a used manual die cutting machine that is located in United Kingdom.

Clicker Presses

Popular in the leather, textile, and foam industries, clicker presses use a swinging arm with hydraulic or pneumatic pressure to push dies through materials. They're valued for their combination of force and precision when cutting thicker materials. This type of die press machine is especially useful for die cut fabric projects.

The die-cutting machines come in different formats for different needs, defined by their sheet size compatibility, where you can explore options of die cutting machines ranging from small sheet sizes to standard sheet sizes to larger used large-sized sheets to best fit your projects.

What is a die?

A die is a specialized tool used to cut and shape packaging materials using a press. Die cutting dies are for die cutting machines that are made of durable materials designed for repeated use.

You can think of a die as a 'mold' that is shaped in the specific way needed to cut out your custom packaging. Ultimately the first step to manufacturing your custom packaging is to form your die. A die is created using tools and die makers to form your custom die before mounting it onto a press. A die paper cut machine requires properly designed dies to function effectively.

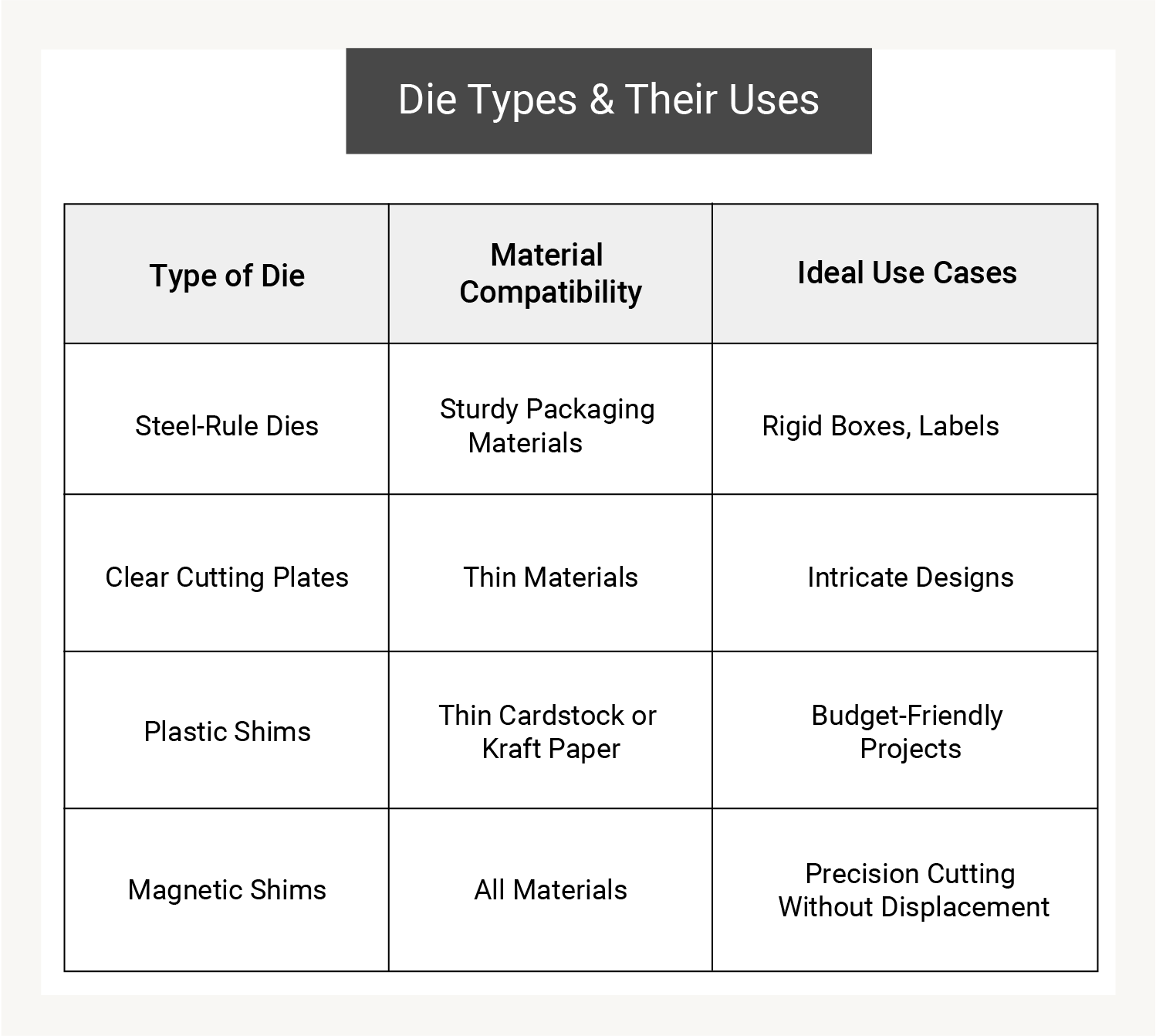

What are the types of Die in Die Cutter?

Many types of dies are available to shape your packaging, labels, and stickers. Here are some popular types that are commonly used in the market:

Steel-Rule Dies: They are highly popular for cutting objects like packaging, labels, and stickers because they can make sharp borders and edges. The durable steel makes these dies excellent for cutting sturdy packaging like rigid boxes.

Clear Cutting Plates: Two transparent dies are used to sandwich the material you want to cut. These dies are excellent for cutting intricate designs.

Plastic Shims: Inexpensive yet durable dies that perfectly fit in the cutting machine to shape thin objects like cardstock or kraft packaging.

Magnetic Shims: Other types of dies may be displaced when they pass through the machine. However magnetic shims stick to their place firmly and help cut the part without getting displaced.

Why is Die Cutting Crucial in Packaging?

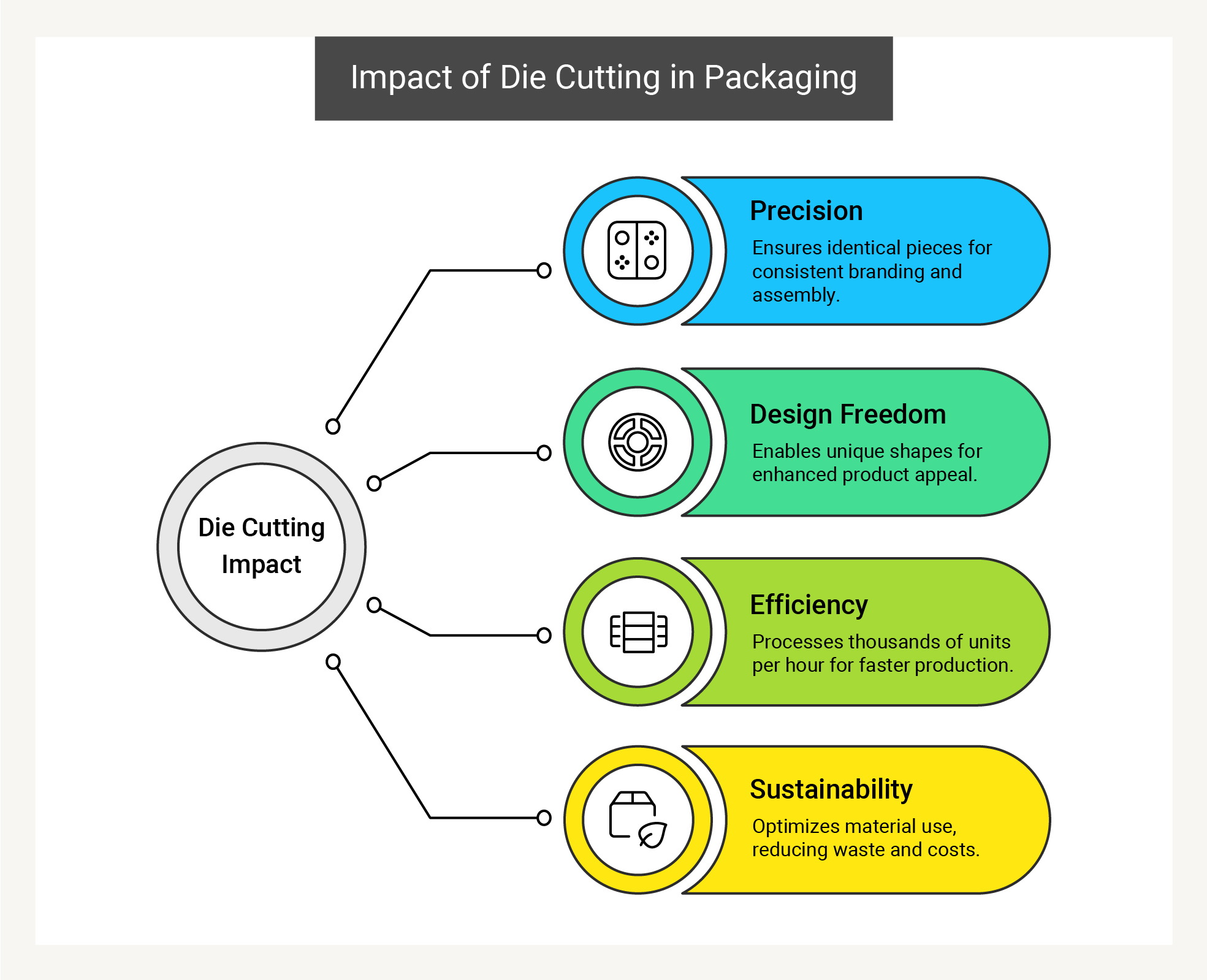

Die cutting has become indispensable in the printing and packaging industry for several reasons:

Precision and Consistency: Die cutting ensures every piece is identical, maintaining brand standards and enabling reliable assembly of packaging components.

Design Freedom: The technology allows designers to move beyond square boxes and rectangular labels, creating distinctive shapes that enhance brand recognition and product appeal.

Efficiency: Modern die cutting machines can process thousands of units per hour, dramatically reducing production time compared to manual cutting methods.

Material Optimization: Die cutting minimizes waste by efficiently arranging cutting patterns, an important consideration for sustainability and cost control.

What is a die cutting machine used for?

Die cutting technology finds application across numerous sectors:

Retail Packaging: From elegantly shaped boxes to hang tags and window displays, die cutting creates packaging that stands out on shelves.

Labels and Stickers: Custom shapes and perforations enhance label functionality and visual appeal.

Promotional Materials: Business cards, brochures, and promotional items with unique shapes create memorable marketing touchpoints.

Industrial Packaging: Precision-cut foam inserts protect delicate products during shipping.

Food and Beverage Packaging: Die-cut windows allow consumers to see products while maintaining package integrity.

Medical Packaging: Sterile packaging for medical devices often requires intricate die-cut designs to ensure both protection and ease of access.

Fabric Cutting:A fabric cutting machine often utilizes die cutting technology for precision cuts in textiles. A fabric cutter with die cutting capabilities can handle multiple layers with consistent results.

Crafting: Die cutting machines for crafting have become popular among hobbyists who want to create professional-looking projects. A craft cutting machine offers versatility for various creative endeavors.

Now we understand the basics, the next step is knowing how to choose the right die-cutting machine for your specific needs. Our guide on how to buy the right die-cutting machineoffers detailed insights into selecting the perfect model.

How to Choose a Die Cutting Machine?

Selecting the right die cutting machine requires careful evaluation of:

Production Volume: Higher production needs typically require automated systems like rotary die-cutters, while lower volumes might be served by flatbed or manual options.

Material Types: Different machines handle various materials and thicknesses. Consider whether you'll be cutting paper, cardboard, plastics, textiles, or other materials.

Required Precision: Some applications demand extremely tight tolerances that only certain machines can achieve.

Changeover Frequency: If your production requires frequent design changes, digital die-cutters or systems with quick-change dies may be worth the investment.

Available Space:Die cutting machines, especially industrial models, require significant floor space that must be accounted for. Large format die cutting machines need substantial installation space.

Budget Considerations: Initial investment, operational costs, maintenance requirements, and expected return on investment should all factor into purchasing decisions. Refurbished machines offer an affordable way to fulfill printing business needs. At Machine Dalal, we have an extensive selection of die cutting machines. Check out this used die cutter in excellent condition with immediate availability.

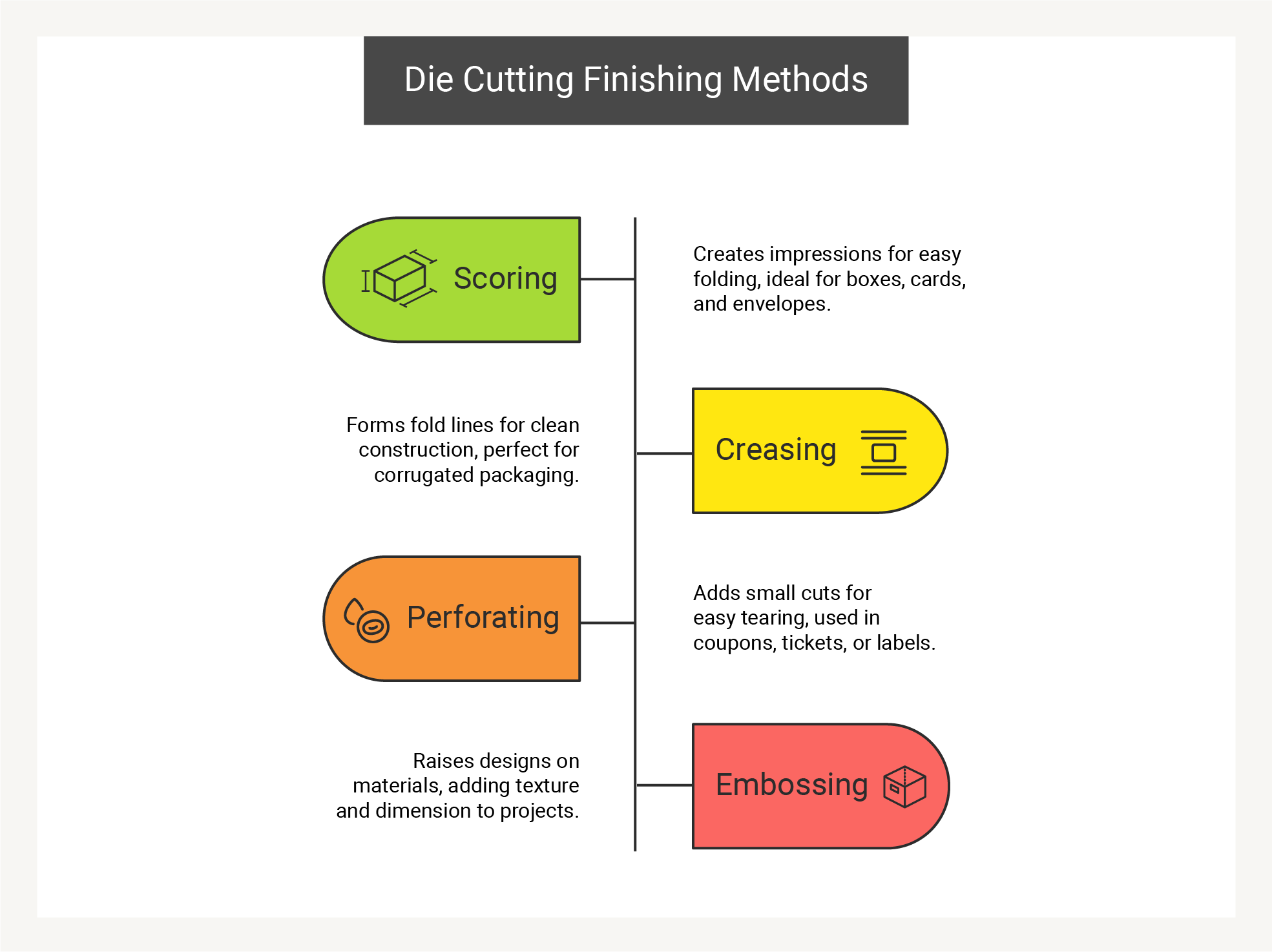

What are Different Die Cutting Finishing Methods?

Scoring

Scoring involves creating an impression or partial cut on the material without slicing through it entirely. This technique is ideal for adding fold lines, making it easier to assemble items like boxes, cards, or envelopes.

Creasing

Creasing creates prominent fold lines that guide the material for easy construction. This is particularly useful for corrugated packaging, ensuring structural integrity and clean folds.

Perforating

Perforating leaves a series of small cuts along a specified line, allowing for easy tearing. It’s commonly used for creating tear-off coupons, tickets, or detachable labels.

Embossing

Many die cutting machines also double as a machine for embossing, adding another dimension to your projects. Embossing creates raised designs on paper and other materials, complementing the die cutting process beautifully.

Paper Cutter Machine Integration

Some modern facilities integrate die cutting machines with paper cutter machine guillotine cutter systems for complete material processing solutions.

Automatic vs Manual Die-Cutting Machines

When selecting a die-cutting machine, consider the differnces between automatic and manual die cutting machines:

Feeding:Automatic machines continuously feed sheets, increasing efficiency, while manual machines require hand-feeding.

Pressure: Automatic machines exert 250-300 tonnes, ensuring clean cuts in a single pass. Manual machines require more adjustments due to lower pressure.

Knife Balancing:Automatic systems balance knives efficiently, though makeready can be longer. Manual systems need heavy packing for balancing.

Cutting Layouts:Automatic machines excel in single-cut jobs; manual machines may need double cuts due to lower tonnage.

Inline Stripping: Automatic machines offer inline stripping for waste removal, reducing labor. Manual machines require separate labor for this.

Repeatability: Automatic machines repeat jobs easily using thin cutting plates. Manual machines need new makeready for each job.

How to Buy a Die Cutting Machine on Machine Dalal

Buying a die cutting machine on Machine Dalal is simple and efficient. Follow these steps:

Visit the Website: Go to machinedalal.com

Create an Account:Sign up if you don't already have an account.

Search for Machines: Use the search bar to find die cutting machines by keywords or brands.

Filter Results: Narrow your search using filters like type, brand, condition, and price range.

Review Listings: Click on listings to view specifications, images, and pricing details.

Contact the Seller: Reach out to the seller via email or phone for inquiries or negotiations.

Buying a die cutting machine on Machine Dalal is simple and efficient. View this used die cutting machine as an example of how easy it is to connect to the seller and check out the machinery details through the platform.

How to do Maintenance of Die Cutting Machines?

Proper maintenance extends machine life and ensures consistent quality:

Regular Cleaning: Removing material debris prevents buildup that can affect cutting precision and machine performance.

Die Maintenance:Dies must be kept sharp and free of damage. Regular inspection and professional resharpening when necessary are essential.

Lubrication Schedule: Following manufacturer recommendations for lubricating moving parts prevents premature wear.

Calibration: Periodic adjustment ensures the machine maintains proper alignment and pressure settings.

Operator Training: Well-trained operators can spot issues before they become serious problems and handle the equipment properly to prevent damage.

How to Troubleshoot Common Die Cutting Machine Issues?

Even well-maintained machines occasionally encounter problems:

Incomplete Cuts: Often caused by insufficient pressure, dull dies, or incorrect machine settings.

Misaligned Cuts: Usually result from improper material feeding or die positioning.

Material Jamming: Typically stems from inappropriate material thickness, speed settings, or debris accumulation.

Excessive Die Wear: Can be caused by cutting materials beyond the machine's specifications or improper pressure settings.

Registration Problems: Often occur when printing and die cutting processes aren't properly aligned in multi-step production.

Popular Brands of Die Cutting Machine

The industry features several respected manufacturers known for quality and innovation:

Bobst: Renowned for high-end packaging die cutting solutions with exceptional precision and durability.

Heidelberg: A leader in printing technology that offers sophisticated die cutting equipment for commercial printing applications.

Kosbridge: Known for versatile digital cutting systems popular in signage and display production.

Monu Graphics: Specializes in compact yet powerful die-cutters for commercial printing operations.

KAMA: Offers custom die cutting solutions for industrial applications across various industries. Their commercial die cutter models are popular in mid-sized businesses.

Pfaeffle: Known for innovative die cutting technology, offering high-performance machines designed for both small and large production runs.

Erba: Specializes in flexible and customizable die cutting solutions tailored for small to medium-sized businesses in the packaging sector.

Iberica: Recognized for reliable and efficient die cutting machines widely used in the European packaging industry with a focus on sustainability.

Duplo: A leader in digital die cutting technology, providing integrated solutions that enhance print finishing and workflow efficiency for commercial printers.

Rabolini: Renowned for durable, high-capacity die cutting machines ideal for complex packaging tasks in various industries.

Each die cut manufacturer brings unique strengths to their product lines and die cutting dealers can help match your needs with the right machine. For a comprehensive overview, check out the blog on Top 10 die-cutting machine manufacturers.

How to Sell Die Cutter on Machine Dalal?

For those looking to sell used die cutting equipment, Machine Dalal provides an effective marketplace platform:

Machine Listing Process

Create an account on the Machine Dalal platform and verify your details.

Navigate to the "Sell Equipment" section and select the appropriate category for your die cutting machine.

Provide detailed specifications including make, model, year of manufacture, condition, and usage history.

Upload high-resolution images showing the machine from multiple angles.

Add video of the machine in operation, demonstrating its cutting capabilities.

Quality visual documentation significantly increases buyer confidence and can lead to faster sales at better prices.

Final Word

Die cutting machines represent a perfect blend of traditional manufacturing principles and modern technology. From humble beginnings in the shoe industry to today's computer-controlled precision systems, these machines continue to transform the printing and packaging landscape. As consumer expectations for distinctive packaging grow and sustainability concerns mount, die cutting technology will remain at the forefront of packaging innovation. Whether you're a small craft business owner considering your first manual die-cutter or an industrial manufacturer evaluating high-volume rotary systems, understanding the fundamentals of this technology is essential for making informed decisions that balance quality, efficiency, and cost-effectiveness.

FAQs

How Does a Die Cutting Machine Work?

Die cutting machines use dies (sharp, shaped blades) to cut through materials. Depending on the machine type, it can employ flatbed, rotary, or laser cutting methods

What are die cutting machines used for?

Die cutting machines cut, shape, or form materials for applications like packaging (boxes, cartons), labels (stickers, barcodes), and industrial parts (gaskets, insulation). They are essential for precision and efficiency in manufacturing.

What's the difference between die cutting and laser cutting?

Die cutting uses physical dies to cut materials, while laser cutting uses focused light beams. Die cutting is typically faster for high-volume production, while laser cutting offers more flexibility for changing designs without tooling costs.

What type of cutting dies does a rotary die cutting machine use?

A rotary die cutting press uses two types of cylindrical dies.

Solid dies are solid metal cylinders with permanently machined shapes.

Flexible/magnetic dies (mag-dies) use a magnetic cylinder wrapped with a thin metal sheet that has embossed cutting blades, allowing quick swaps for flexibility.

What Types of Materials Can Be Cut with a Die Cutting Machine?

Die cutting machines handle a variety of materials, including:

Paper: Coated paper, kraft paper, and cardboard.

Film: PE, PET, and BOPP films.

Labels: Adhesive labels and vinyl stickers.

Others: Foam, rubber, and thin metals.

Is there affordable die cutting machine options for small businesses?

Yes, there are many affordable cutting machine options available, including manual die cutting machines and entry-level digital cutters. Even cheap cutting machines can deliver good results for basic applications.

Machine Dalal is a global trading platform for buyers and sellers of print, packaging and converting equipment to connect directly and trade their machinery.

Machine Dalal is the global trading platform for the printing, packaging, and converting industry—designed to evolve with the needs of the market. We are continually innovating - from powerful search tools to integrated social media marketing, a growing newsletter audience, and our newly launched digital magazine, we are building a robust ecosystem to support print machinery sellers and buyers worldwide.

For a more personalized experience, download our mobile apps on Android and iOS.

To explore business opportunities or partnerships, feel free to get in touch with us.

The World of Print at your Fingertips

The Machine Dalal Mobile Apps

Download our Machine Dalal App Regular updates from our magazine with illustrations, innovations , commodities, history, media, art and a whole lot more from the magnificent world of Print.

Get the App

Login

Login