30/04/2025

Complete Guide to Bag Making Machines: Types, Features, and Uses

Everything you need to know about bag making machine for paper, plastic and non-woven bags.

The global demand for bags-ranging from eco-friendly paper carriers to robust plastic and non-woven options-has surged in recent years. As businesses and consumers increasingly prioritize sustainability, efficiency, and customization, bag making machines have become essential assets for manufacturers. This comprehensive guide explores the main types of bag making machines, their key features, and the diverse applications that drive their adoption across industries.

What is a Bag Making Machine?

Let’s start with the basics. A bag making machine is a specialized piece of equipment designed to manufacture various types of bags from materials like plastic, paper, fabric, or laminated sheets. It automates the folding, gluing, and sealing processes to produce bags efficiently.

These machines typically consist of:

A feeding/loading unit to input the raw material

A rotating molding head with upper and lower molds to shape the bag

A sealing device to securely close the bag openings

The technology allows for continuous high-speed production of bags in different shapes (square, rectangular, triangular, etc.) and sizes without seams or creases.

Key Features of Bag Making Machines

Selecting the right bag making machine requires careful consideration of several critical features that influence efficiency, versatility, and product quality.

Automation and Efficiency

Modern machines are increasingly automated, reducing labor costs and minimizing human error. Automated systems handle everything from raw material feeding to cutting, folding, gluing, and stacking, ensuring consistent output and high production speeds. Fully automatic machines can produce hundreds or even thousands of bags per hour, meeting the demands of large-scale manufacturers.

User-Friendly Controls

Touch-screen interfaces and integrated control systems allow operators to easily adjust machine settings, monitor production in real time, and troubleshoot issues quickly. This user-centric design enhances productivity and reduces downtime.

Versatility

The ability to switch between different bag sizes, styles, and materials is a hallmark of advanced bag making machines. Versatile machines can accommodate various paper weights, plastic film thicknesses, and non-woven fabrics, enabling manufacturers to adapt to changing market demands.

Customization Capabilities

Many machines offer in-line printing, handle attachment, gusset formation, and other customization options. This flexibility allows manufacturers to produce branded, functional bags tailored to specific customer requirements.

Durability and Maintenance

Industrial-grade construction ensures long-term reliability, while features like auto-lubrication and easy-access components simplify maintenance. Machines made from stainless steel and other robust materials withstand the rigors of continuous operation.

Production Speed

High-speed operation is essential for meeting large orders efficiently. Production speeds vary by machine type and automation level, with some models capable of producing up to 25,000 pieces per hour.

Types of Bag Making Machines

Bag making machines are engineered to handle specific materials and bag styles. Understanding the main categories helps manufacturers select the right solution for their needs.

Paper Bag Making Machines

Paper bag making machines are at the forefront of the movement toward sustainable packaging. These machines are available in various configurations, each tailored to specific bag designs and production requirements:

Square Bottom Paper Bag Machines: Produce sturdy, flat-bottomed bags ideal for groceries, retail, and food packaging. Fully automatic models can achieve speeds of 150–200 bags per minute, while semi-automatic variants produce 80–100 bags per minute.

V Bottom Paper Bag Machines: Known for their unique V-shaped base, these bags are popular in supermarkets and retail. Fully automatic machines can reach up to 1,500 bags per minute.

Handle Making Machines: Dedicated to producing rope or paper handles, which can be attached to bags for added strength and convenience. These machines typically produce 100–200 handles per minute.

Printing and Packing Machines: Integrated systems allow for branding and efficient post-production packing, streamlining the entire process from raw material to finished, branded product.

Plastic Bag Making Machines

Plastic bag making machines are designed for high-volume, versatile production. They are classified by the type of bag they produce and the materials they process:

T-Shirt Bag Making Machines: Specialize in the production of “T-shirt” style bags with strong handles, commonly used in supermarkets and retail. They can process HDPE, LDPE, biodegradable, and recycled films, with automated punching and strong seam formation for durability.

Pouch Bag Making Machines: Used for food, medical, and cosmetic packaging, these machines can create flat, stand-up, and gusseted pouches from PE, PET, and laminated films. They often include advanced sealing and optional printing features.

Garbage Bag Making Machines: Engineered for municipal, household, and commercial cleaning applications, these machines handle HDPE, LDPE, and recycled materials, producing bags with various features such as drawstrings and perforations.

Bag on Roll Machines: Produce continuous rolls of bags-such as produce or garbage bags-with easy-tear perforations, ideal for supermarkets and public facilities.

Side Seal Bag Making Machines: Create bags sealed along the sides, offering enhanced vertical tensile strength and suitability for a range of products, including lightweight and moderately heavy items.

Non-Woven Bag Making Machines

Non-woven bag making machines are gaining popularity due to their ability to produce reusable, durable bags from spun-bonded polypropylene fabrics. These machines often include features for automatic handle attachment, cutting, and printing, making them ideal for promotional and shopping bags.

Uses and Applications

Bag making machines serve a wide array of industries, each with unique packaging needs:

How Paper Bag Making Machine Works

Roll Paper Feeding

Roll paper feeding is the first step of making a paper bag with a paper bag making machine. This process takes place with a film unwinding tool which opens the paper films with the help of a feeder roll in and turns it in the form of rolls. The un winded paper goes straight into the feed section of the machine. After this paper roll is fed into the machine with the help of rollers to produce paper bags.

Paper Bag Forming

This is the next step where paper material goes through the temperature regulated process for effective film sealing. You can manage the duration, temperature, and quantity through the square bottom paper bag making machine. Now the sealed films go through some process that reduces their temperature.

Paper Bag Cutting

A paper bag making machine includes shaped blades that move upside down. These blades cut the paper materials according to the type of paper bag you want to make after the completion of the film sealing step. It can vary from machine to machine.

Shape Folding

Paper bag cuttings transfer into the folding section in the machine after the paper bag cutting process. The mechanical and advanced arms of the folding section fold the paper cutting to create the basic structure of the paper bag.

Paper Bag Gluing

Now the proper folded paper cuttings into the shape requires going through the gluing process. The paper bag making machine applies the glue to protect the bag edges and seams. These machines also protect the paper bags from excess adhesive application as well.

End Folding

The partially produced paper bags go through machine rollers after the gluing process. These rollers press the paper bags to increase the stability of the paper bag. It enables these bags to unwind straight correctly when filed.

Finished Paper Bags

Now the paper bag making process ends and all the produced bags get transferred to the stackers and conveyors as per the machine design for further process. Paper bags are now ready for distribution and usage.

Sustainability Trends

With growing environmental concerns, there is a marked shift toward machines that can process biodegradable materials, recycled plastics, and renewable resources. Paper and non-woven bag making machines are especially popular among businesses seeking to reduce their ecological footprint.

How Bag Making Machines Enhance Production?

Bag making machines offer several advantages that drive their widespread adoption:

Scalability: Automated machines enable manufacturers to scale up production quickly to meet surges in demand without sacrificing quality.

Consistency: Precision engineering ensures uniform bag size, strength, and appearance, which is crucial for brand reputation and operational efficiency.

Cost Savings: Automation reduces labor requirements and material waste, resulting in lower per-unit costs and higher profitability.

Customization: In-line printing and handle attachment allow for on-demand branding and functional enhancements, adding value for end-users.

How to Maintain Bag Making Machine?

By prioritizing routine care, you not only extend the machine's lifespan but also enhance its performance, keeping your operations smooth and productive.

Prioritize daily cleaning of your non-woven bag making machine to prevent dust and debris buildup, ensuring high-quality output and extending the machine's lifespan.

Regularly inspect and lubricate moving parts to minimize friction and wear, which is crucial for maintaining optimal performance and preventing breakdowns.

Conduct comprehensive inspections weekly to identify potential issues early, using a detailed checklist to ensure no critical areas are overlooked.

Test and adjust calibration settings weekly to guarantee consistent bag dimensions and quality, enhancing both durability and print clarity.

Avoid common maintenance mistakes such as skipping lubrication or using non-compatible replacement parts, as these can lead to costly repairs and inefficiencies.

Keep a stock of spare parts to facilitate quick replacements, reducing downtime and maintaining a smooth production flow.

Incorporate troubleshooting practices for common issues like power problems or poor bag quality to minimize disruptions and maintain production efficiency.

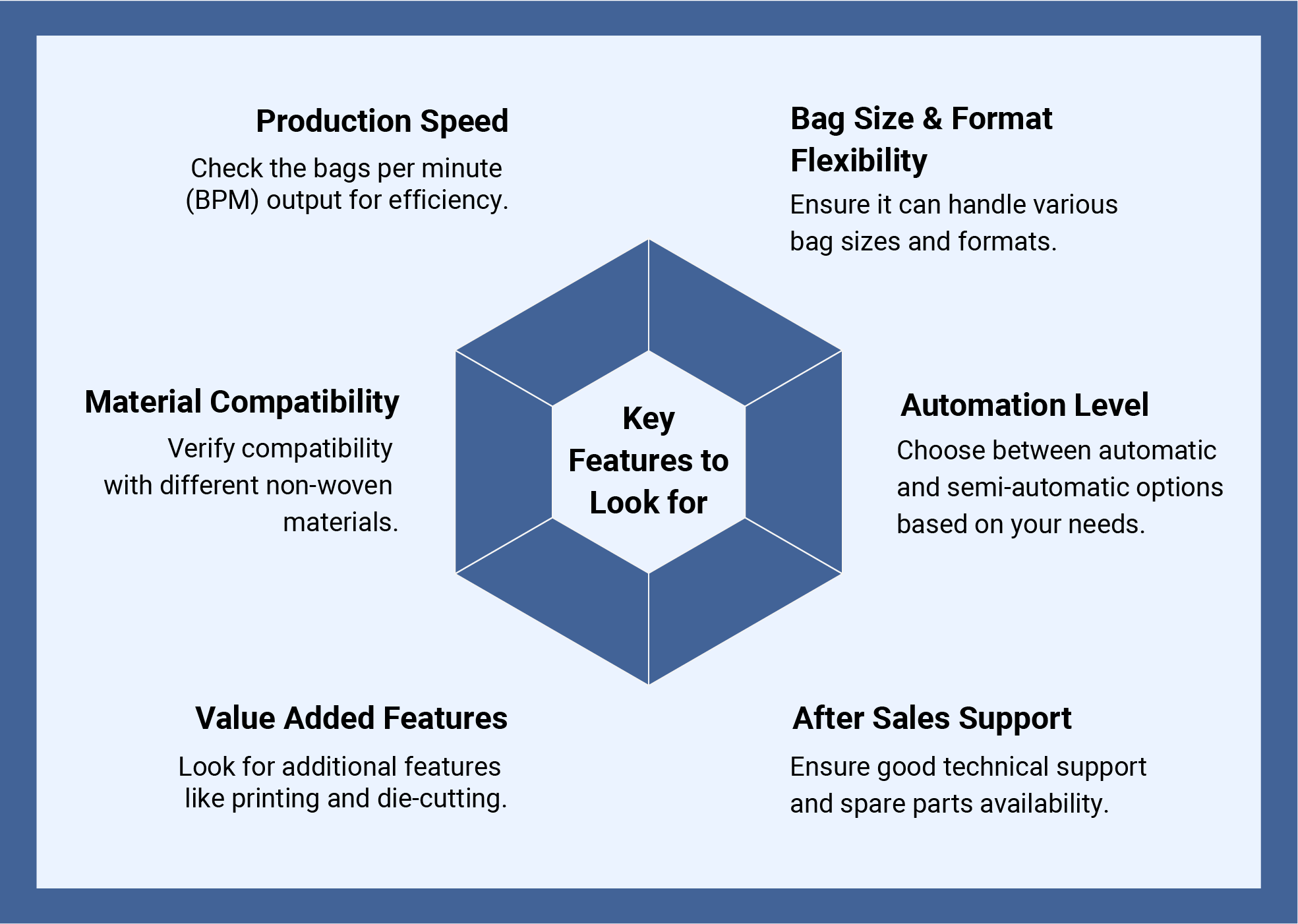

How to Choose the Right Bag Making Machine?

When selecting a bag making machine, manufacturers should consider:

Type of Material: Paper, plastic, or non-woven fabric.

Bag Style and Size: Square bottom, V bottom, T-shirt, pouch, etc.

Production Volume: Required output per hour or day.

Customization Needs: Printing, handle types, gussets, etc.

Automation Level: Manual, semi-automatic, or fully automatic.

Budget and ROI: Initial investment versus expected efficiency gains.

Bag making machines are the backbone of modern packaging, enabling businesses to meet the growing demand for functional, sustainable, and customizable bags. By understanding the different types of machines, their features, and their applications, manufacturers can make informed decisions that enhance productivity, reduce costs, and support sustainability goals. As technology continues to advance, bag making machines will play an increasingly vital role in shaping the future of packaging across industries

What is a bag making machine?

A bag making machine is an industrial device designed to automate the process of producing bags from various materials such as paper, plastic, or non-woven fabric. These machines handle tasks like cutting, folding, sealing, printing, and sometimes attaching handles, resulting in finished bags ready for use in retail, food packaging, waste management, and more.

What types of bags can be made with these machines?

Bag making machines can produce a wide range of bag styles, including:

T-shirt bags (also known as carry bags or grocery bags)

Square bottom paper bags

V bottom paper bags

Pouch bags (flat, stand-up, gusseted)

Garbage bags

Non-woven shopping bags

Bag on roll (perforated rolls for easy tear-off)

Custom printed and handled bags

Which industries use bag making machines the most?

Bag making machines are widely used in:

Retail and supermarkets

Food and beverage packaging

Healthcare and pharmaceuticals

Hospitality and tourism

Cleaning and waste management

E-commerce and logistics

How do I choose the right bag making machine for my business?

Consider the following factors:

Material type (paper, plastic, non-woven)

Bag style and size

Required production volume

Customization needs (printing, handles, gussets)

Automation level (manual, semi-automatic, fully automatic)

Budget and expected return on investment

Machine Dalal is a global marketing and trading platform for print, packaging and converting industry. Its core mission is to facilitate direct, commission-free trading of print machinery, connecting buyers and sellers from around the world and fostering business relationships that often lead to repeat sales.

Machine Dalal is the global trading platform for the printing, packaging, and converting industry—designed to evolve with the needs of the market. We are continually innovating - from powerful search tools to integrated social media marketing, a growing newsletter audience, and our newly launched digital magazine, we are building a robust ecosystem to support print machinery sellers and buyers worldwide.

For a more personalized experience, download our mobile apps on Android and iOS.

To explore business opportunities or partnerships, feel free to get in touch with us.

The World of Print at your Fingertips

The Machine Dalal Mobile Apps

Download our Machine Dalal App Regular updates from our magazine with illustrations, innovations , commodities, history, media, art and a whole lot more from the magnificent world of Print.

Get the App

Login

Login