Latest Articles

Machine Dalal Services

Explore Blog Categories

Release Notes

Latest information about the changes, updates, and improvements made to the software and application.

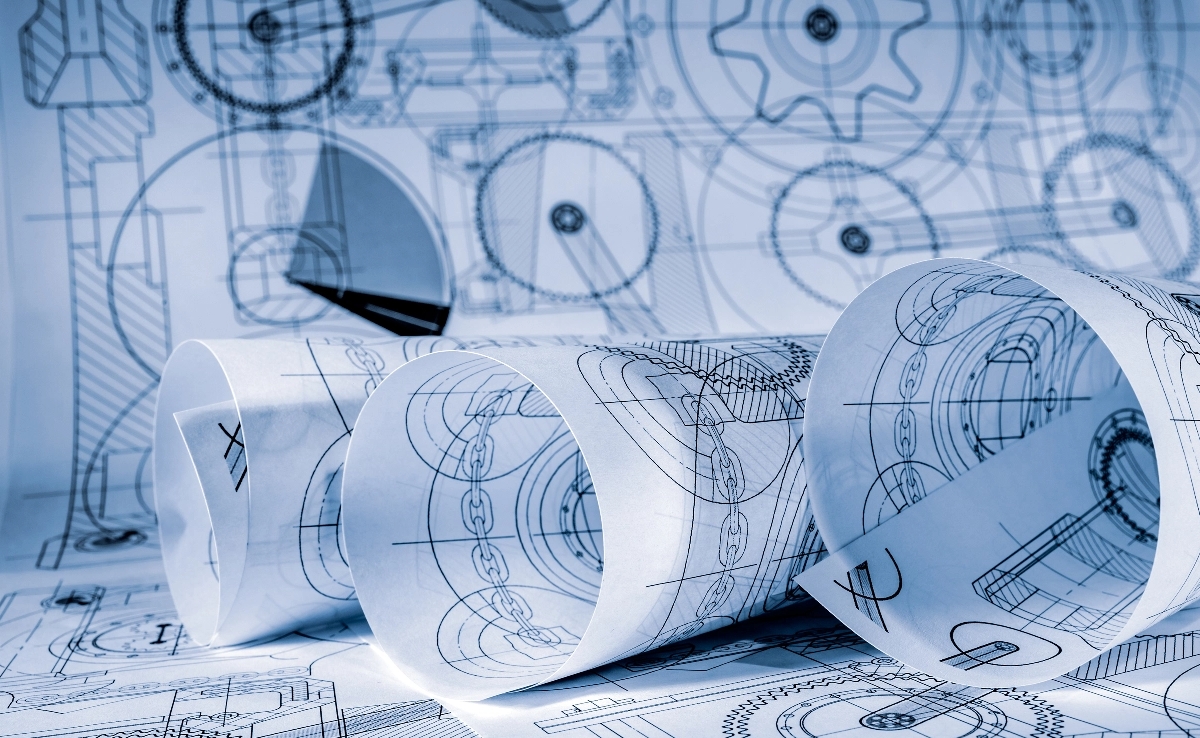

Read BlogMachine Dalal Magazine

Delve deeper into the world of graphic design, the history and evolution of print processes and packaging.

Read Blog

Founder's Desk

Offers a deeper understanding of the principles, goals, and values that guide the platform.

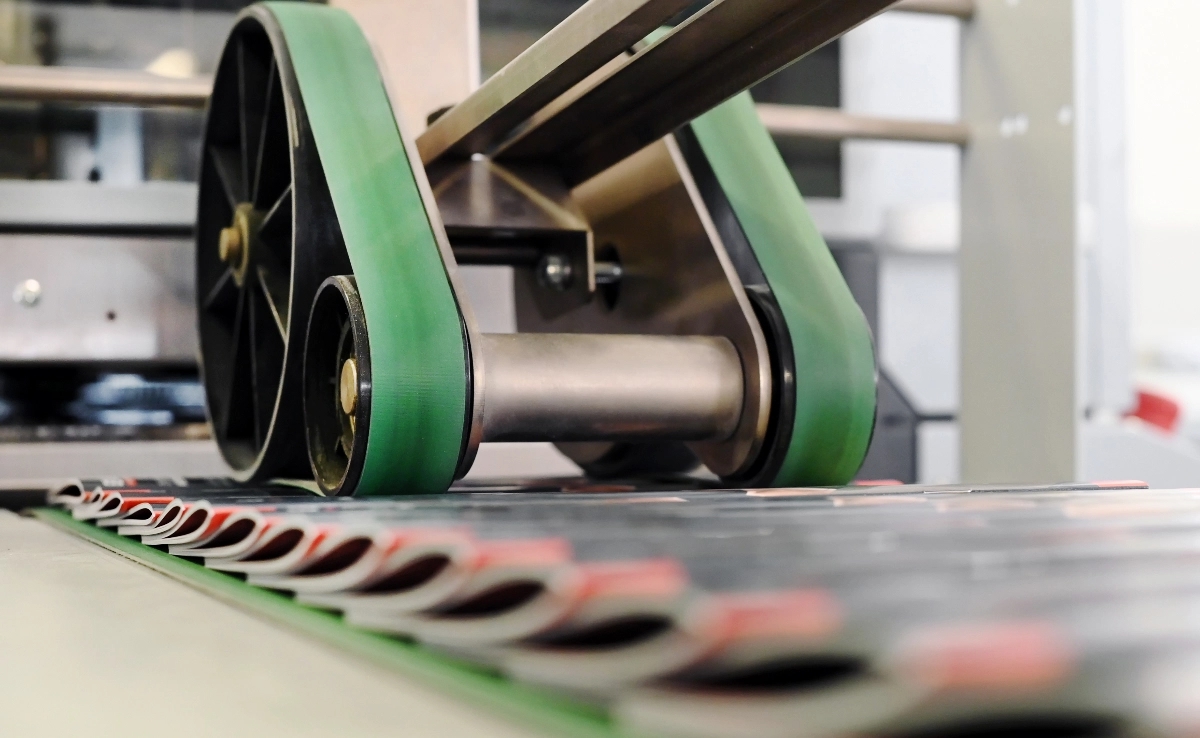

Read BlogMachinery & Equipment

Features in-depth information about listed print machinery including specifications, location and features for informed decision-making.

Read Blog

Resources

Find information and tools to simplify the buying, selling, and managing your equipment listing on Machine Dalal.

Read Blog

The World of Print at your Fingertips

The Machine Dalal Mobile Apps

Download our Machine Dalal App Regular updates from our magazine with illustrations, innovations , commodities, history, media, art and a whole lot more from the magnificent world of Print.

Get the App

Login

Login