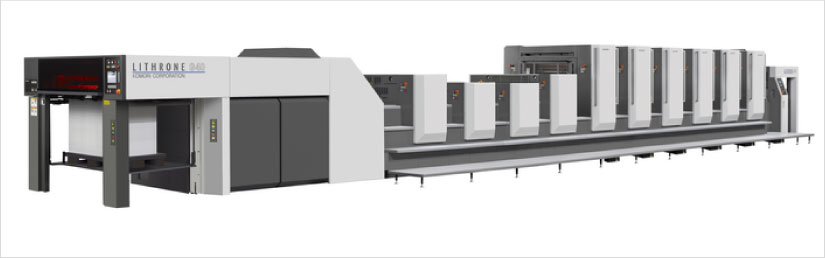

The Lithrone G40 was developed to be a high performance press that attains both high productivity and high print quality by means of stable operation. With stable operation as the principal theme, the all-important basic performance parameters were re-evaluated from the beginning and Komori’s high-order technologies were concentrated on stable sheet feeding and delivery. The Lithrone G40 was developed to be the next-generation production machine. Specifically, the new feeder with the newly developed suckers, feeder board, register and front register provides unfailing support for operation with a wide range of sheet thicknesses – from ultrathin to thick sheets – enabling utterly reliable printing at the maximum speed of 16,500 sheets per hour. In addition, the extension of the high-speed followup control function to support higher speed operation and the air control presets (optional) managed by the standard KHS-AI with self-learning function enable very efficient paper changeover, which is crucial for work with many short-run orders for a variety of different printed products. Throw any job at the G40, from thin stock to board, and it’s off and running. The Lithrone G40 ensures high quality print with unsurpassed productivity. The G40 was developed to reduce the carbon footprint of print, and with its reduced energy consumption, low makeready waste, and a maximum speed of 16,500 sheets per hour, the G40 is the ultimate high performance printing machine. All controlled with Komori’s advanced KHS-AI software.

| Number of Colors | 2-8 units |

| Maximum Print Speed | 16,500sph |

| Maximum Sheet Size | 28-11/32" x 40-9/16" |

| Minimum Sheet Size | 14-3/16" x 20-15/16" |

| Sheet Thickness Range | .0016"-.0315" |