Pouch Packing Machine SPS 1000 - Smart Pack

Pouch Packing Machine SPS 1000 - Smart Pack

Machine Overview

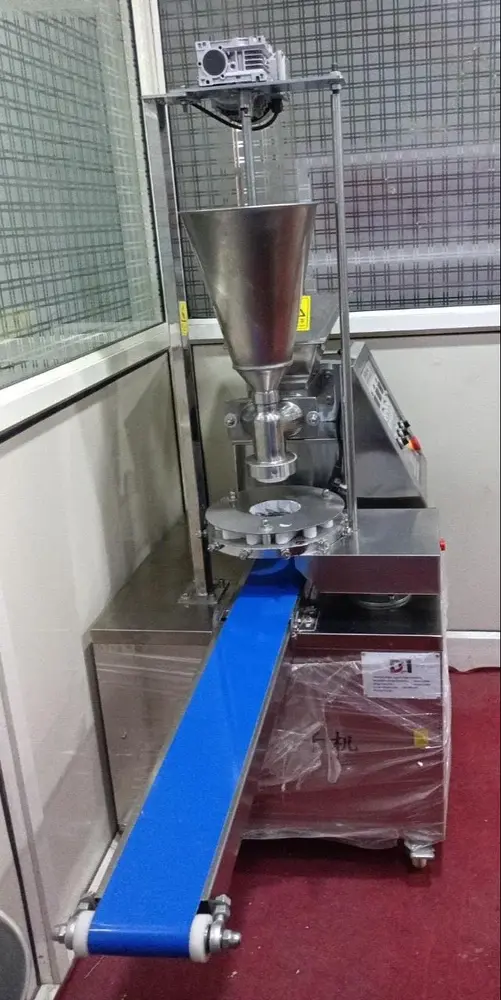

The Pouch Packing Machine SPS 1000 is an indispensable device for businesses in the oil industry seeking a reliable and efficient solution for packaging oil. This vertical form fill seal machine is designed to streamline the process of supplying oil by offering precise control and automated operations.

Driven by a single-phase motor and a reduction gearbox, this machine ensures smooth and consistent performance. Its mechanical cam and electrical cam systems control the movements of the jaws, film feed, sealing, cooling, and film feed duration.

With its specially designed former, the machine converts the heat-sealable film roll into a tube, which is then vertically sealed using an impulse-heated electrode. The sachets are sealed and separated from one another through the sealing electrodes while the jaws are closed. The oil from the main tank is pumped into the film tube surrounding the injection pipe, ensuring efficient filling.

About Machine

The Pouch Packing Machine SPS 1000 is an indispensable device for businesses in the oil industry seeking a reliable and efficient solution for packaging oil. This vertical form fill seal machine is designed to streamline the process of supplying oil by offering precise control and automated operations.

Driven by a single-phase motor and a reduction gearbox, this machine ensures smooth and consistent performance. Its mechanical cam and electrical cam systems control the movements of the jaws, film feed, sealing, cooling, and film feed duration.

With its specially designed former, the machine converts the heat-sealable film roll into a tube, which is then vertically sealed using an impulse-heated electrode. The sachets are sealed and separated from one another through the sealing electrodes while the jaws are closed. The oil from the main tank is pumped into the film tube surrounding the injection pipe, ensuring efficient filling.

Features

| Driven by single-phase motor and reduction gearbox, providing reliable and consistent performance. |

| Mechanical cam control of jaws movements and film feed, ensuring in-sync operations. |

| Electrical cam switches back to control sealing, cooling, and film feed duration, optimizing packaging efficiency. |

| Heat-sealable film roll mounted at the rear of the machine, easily accessible for convenient replacement. |

| Horizontal sealing and separation of sachets using sealing electrodes, facilitating efficient packaging. |

| Pump system to fill the film tube surrounding the injection pipe with oil, ensuring accurate and controlled filling. |

Technical Specifications

| Power | 220v /-1% , single Phase |

| Machine Speed | 16-18 pouches/Min. |

| Compressed Air | Not Required |

Application

Pouch Packing For Oil

Easy Financing with Machine Dalal

Business and Machinery Loans available for this model.

Apply in minutes. Get approved fast. Flexible loan options to power your machinery purchase.

Apply Nowtrending_flatGrow Your Machinery Sales

More Exposure. More Leads. More Machinery and Equipment Sales. Reach more Printers, Publishers and Packaging Manufacturers with Machine Dalal.Follow the link to explore Enterprise Services.

Learn Moretrending_flat

Keep Exploring

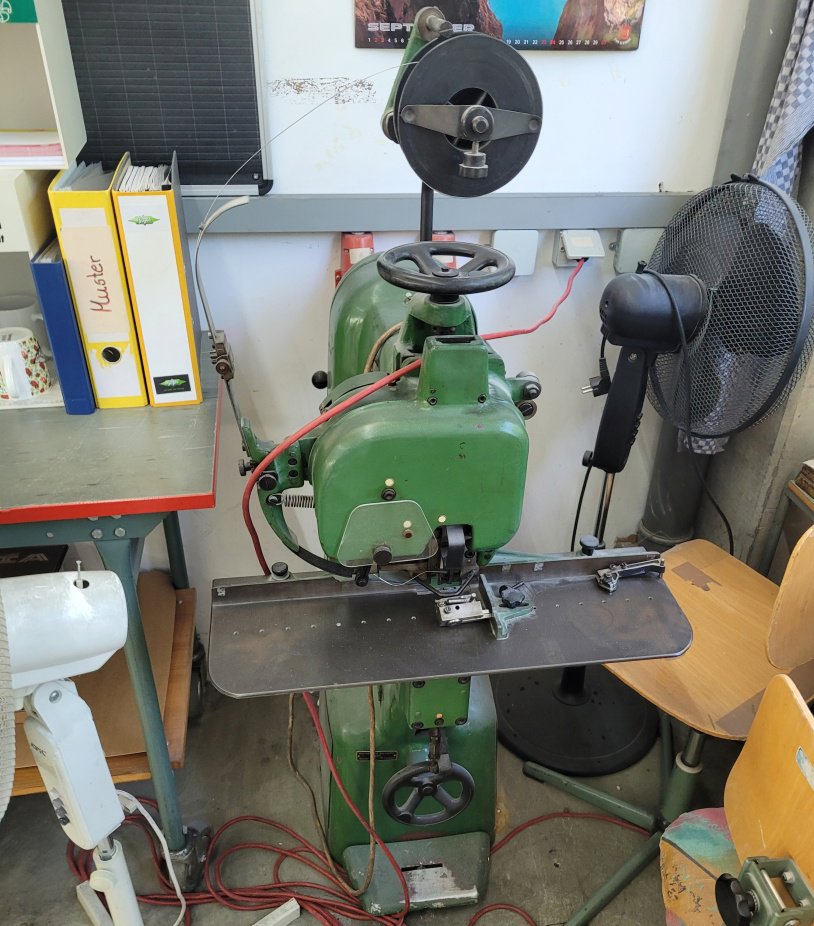

703/1

Stitching Machines

age 1960 wire stitching machine 1 sttiching head electr. drive food switch incl. substructure Ref: PO230340V Please ask for price. We ship and install worldwide!

BST 10

Booklet machines

10 suction air stations BST 10 Format max. 35x50cm Transfer bridge Wire stitching machine AGR-P with 2 Hohner stitching heads Layer folding machine PA-t Front cutter TR-t Sheet press BBP Long stream delivery

The World of Print at your Fingertips

The Machine Dalal Mobile Apps

Download our Machine Dalal App Regular updates from our magazine with illustrations, innovations , commodities, history, media, art and a whole lot more from the magnificent world of Print.

Get the App

Login

Login