Pouch Packing Machine SPLP 1000 - Smart Pack

Pouch Packing Machine SPLP 1000 - Smart Pack

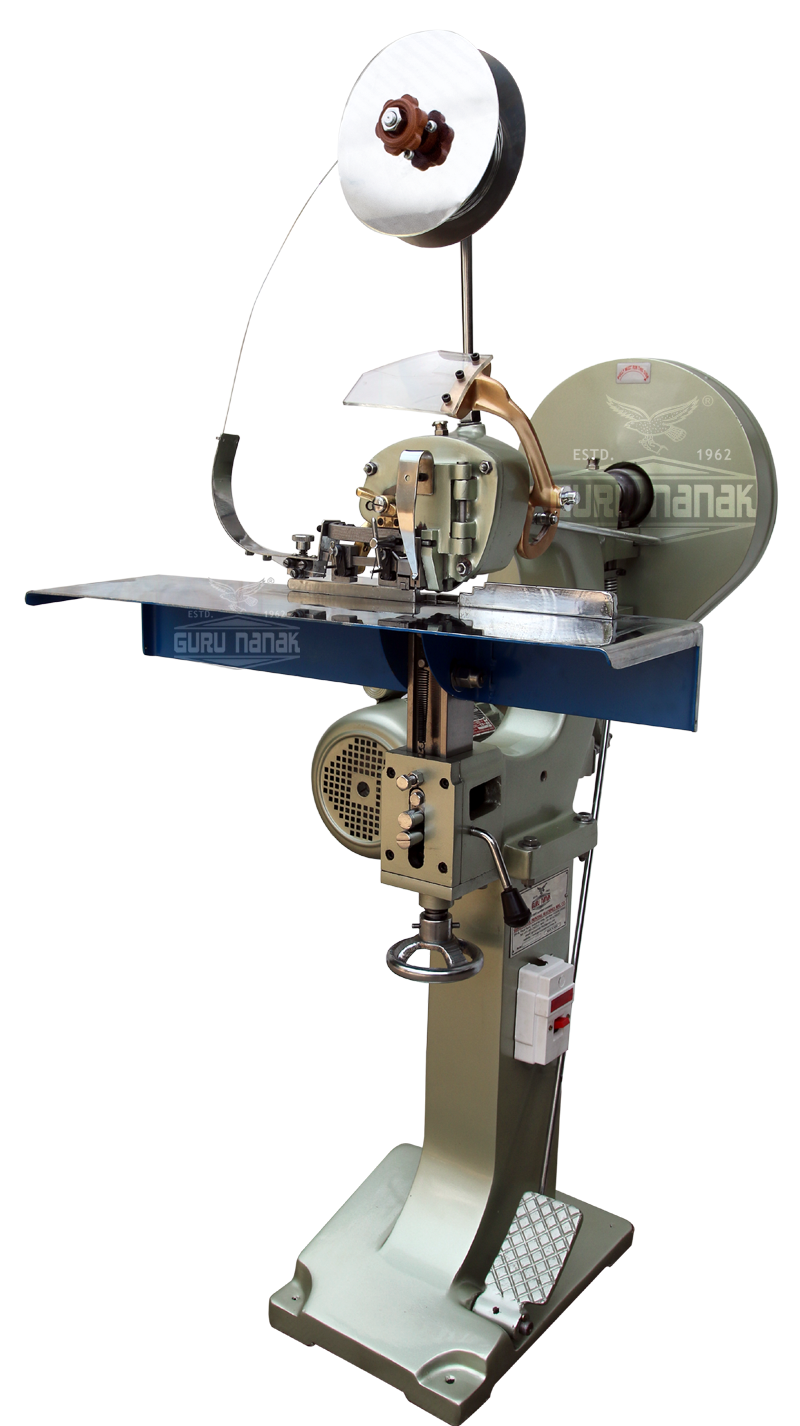

Machine Overview

The SPLP 1000 water pouch packing machine is a must-have for businesses in the water-based industry looking for a reliable and efficient solution for filling and packaging mineral water and other liquids. This fully automatic machine operates on the gravity flow filling principle, allowing water to flow into the bottle based on weight. With its easy operation, low maintenance requirements, and advanced features, this machine ensures consistent and secure packaging of water pouches.

The SPLP 1000 machine is designed for high efficiency and reliability. It offers a compact and mechanically operated design, ensuring smooth and consistent performance. The impulse heating sealing technique guarantees every pouch a secure and leak-proof seal. The machine has a high filling capacity, allowing it to serve multiple pouches simultaneously and easily adjust to different-sized bags without rearranging parts. With a control panel to adjust filling speed and sealing temperature, operators have precise control over the machine settings.

About Machine

The SPLP 1000 water pouch packing machine is a must-have for businesses in the water-based industry looking for a reliable and efficient solution for filling and packaging mineral water and other liquids. This fully automatic machine operates on the gravity flow filling principle, allowing water to flow into the bottle based on weight. With its easy operation, low maintenance requirements, and advanced features, this machine ensures consistent and secure packaging of water pouches.

The SPLP 1000 machine is designed for high efficiency and reliability. It offers a compact and mechanically operated design, ensuring smooth and consistent performance. The impulse heating sealing technique guarantees every pouch a secure and leak-proof seal. The machine has a high filling capacity, allowing it to serve multiple pouches simultaneously and easily adjust to different-sized bags without rearranging parts. With a control panel to adjust filling speed and sealing temperature, operators have precise control over the machine settings.

Features

| Operates on the gravity flow filling principle, ensuring accurate and uniform filling of water pouches. |

| The impulse heating sealing technique provides each pouch with a secure and leak-proof seal. |

| Compact and mechanically operated design for reliable and consistent performance. |

| High filling capacity, allowing the machine to serve multiple pouches simultaneously. |

| Easy adjustment to different-sized bags without rearranging parts, enhancing flexibility. |

Technical Specifications

| Voltage | 220v/50Hz |

| Power | 1750w |

| Packing Capacity | 200-100ml |

| Product Capacity | 1000 bag/hr. |

| Size of Bag in mm (L*W) | 50-210*50-170 |

| Dimension in mm (L*W*H) | 1050*850*1920 |

Application

Water pouch packing machine has their application in water-based industries

Easy Financing with Machine Dalal

Business and Machinery Loans available for this model.

Apply in minutes. Get approved fast. Flexible loan options to power your machinery purchase.

Apply Nowtrending_flatGrow Your Machinery Sales

More Exposure. More Leads. More Machinery and Equipment Sales. Reach more Printers, Publishers and Packaging Manufacturers with Machine Dalal.Follow the link to explore Enterprise Services.

Learn Moretrending_flat

Keep Exploring

The World of Print at your Fingertips

The Machine Dalal Mobile Apps

Download our Machine Dalal App Regular updates from our magazine with illustrations, innovations , commodities, history, media, art and a whole lot more from the magnificent world of Print.

Get the App

Login

Login