Bagmac 305A - Boxmac

Bagmac 305A - Boxmac

Machine Overview

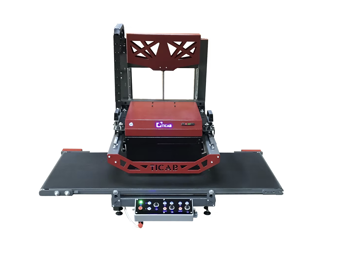

Automatic Roll Feeding Square Bottom Paper Bag Making Machine

Roll Feeding square bottom paper bag making machine forming the paper bag in one process from printed forming, bag formation at a stroke. This machine controls by PC programmable servo motor through the have advantages of high speed, quickly replace the paper bag specifications, more wide range adjusting.or unprinted paper roll, side gluing, folding, paper cutting, bottom folding, bottom gluing, bottom human-machine touch screen interface. It can produce various of specifications paper bags. It is an ideal machine for producing food bag & shopping bag.

About Machine

Automatic Roll Feeding Square Bottom Paper Bag Making Machine

Features

| Full automatic roll feeding kraft paper bag making machine. |

| Introduce PLC and In-touch screen human-machine interface centralized control system, with reliable performance, easy for operation and maintenance. |

| Equipped with Larson & Toubro (L&T) PLC for centralized control system and S ICK photocell for correction, tracking the printed material accurately, minimize the adjustmen t and preset time, increase the production efficiency. |

| Human oriented security protection, whole housing design, ensure the safety of operator. |

| Hydraulic Self Loading Reel Stand with one unwinding shaft. |

| Automatic constant tension control for unwinding, EPC web guider system, motor for material feeding with inverter, minimize the adjustment time for web alignment. |

| High speed oriented design ensure successful of production: within the suitable paper range, production capacity can reach 100- 120pcs/min, even higher, which increases the unit production capacity and gets higher profit. |

| Larson & Toubro (L&T) electric system, ensure better stability and reliability; perfect after sale service, trouble free for The machine can be stop automatically once out of material. |

| Servo motors for main feeding and bag length control Color mark tracking system. On Color error, machine will automatically shut down. |

| Automatic lubricating oil supply system. |

| Paper impress, bottom folding, gluing and bag formation can be completed automatically. |

| Side lay working table, easy operation. |

Technical Specifications

| Bag Width (W) | 180-305 mm |

| Bottom Size (H) | 100- 180 mm |

| Bag Tube Length (C) | 440-710 mm |

| Max.Speed | 200 pcs per min. |

| Paper GSM | 50- 150 gsm |

| Paper Roll Width | 630- 990 mm |

Application

Food bag & shopping bag.

Easy Financing with Machine Dalal

Business and Machinery Loans available for this model.

Apply in minutes. Get approved fast. Flexible loan options to power your machinery purchase.

Apply Nowtrending_flatGrow Your Machinery Sales

More Exposure. More Leads. More Machinery and Equipment Sales. Reach more Printers, Publishers and Packaging Manufacturers with Machine Dalal.Follow the link to explore Enterprise Services.

Learn Moretrending_flat

The World of Print at your Fingertips

The Machine Dalal Mobile Apps

Download our Machine Dalal App Regular updates from our magazine with illustrations, innovations , commodities, history, media, art and a whole lot more from the magnificent world of Print.

Get the App

Login

Login