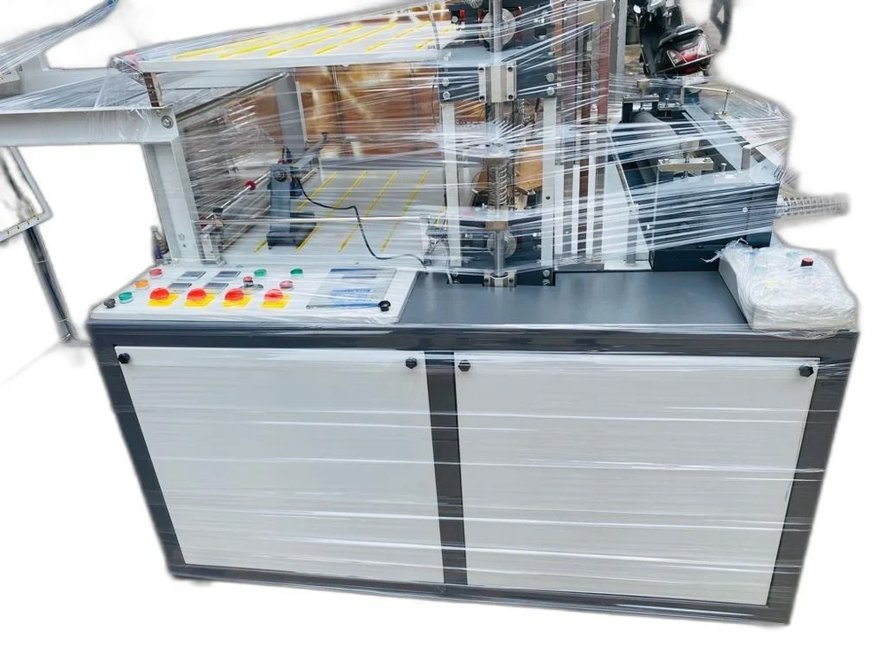

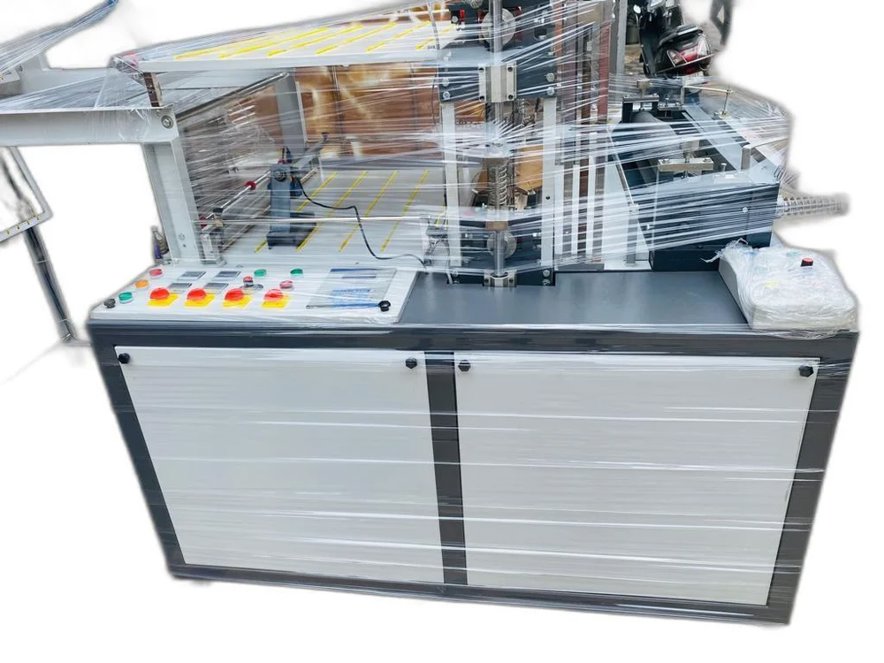

Biodegradable Bag Making Machine - DU

Biodegradable Bag Making Machine - DU

Machine Overview

Technical Specifications

| Max Production Speed | 60-100 |

| Roll size | 5 - 28 Inch |

| Photo Mark censor | Yes |

| Thickness of Bag | 8-90 Micron |

| Length of Bag | 1-100 Inch |

| Width of Bag | 26 Inch |

| Main motor | HP |

Application

Biodegradable Bag , Plastic Carry Bag

Easy Financing with Machine Dalal

Business and Machinery Loans available for this model.

Apply in minutes. Get approved fast. Flexible loan options to power your machinery purchase.

Apply Nowtrending_flatGrow Your Machinery Sales

More Exposure. More Leads. More Machinery and Equipment Sales. Reach more Printers, Publishers and Packaging Manufacturers with Machine Dalal.Follow the link to explore Enterprise Services.

Learn Moretrending_flat

Keep Exploring

TX52/44

Folding Machine

Falzmaschine - Flat Pile Folding Machine Stahl T52/4-4-SAK66 Year 1988 - Serial-No. 36336-88-148120 Folding Size min. 100 x 150mm Folding Size max. 520 x 820mm Folding Type: 1. Unit 4 Buckles - folding width 500mm 2. Unit 4 Buckles - folding width 500mm Pile height max. 690mm Stream delivery SAK 66 Include Compressor Counter - Control PCS 100 Manuals Included

MC-80a

Collator and booklet production

We are pleased to offer: Used Horizon MC-80a MC-80m (Collating Towers) FC-20 (Fore-edge Trimmer) SPF-20 (Stitcher & Folder) Booklet Maker Year 2003 Specification Multi – Modular Air – Suction Collator MC-80a (Main Module) MC-80m (Extension Module) Number of Bins: 8 Sheet Size: 148 x 210 mm to 318 x 470 mm (5.8” x 8.3” to 12.5” x 18.5”) Bin Pile Height: 50 mm (2”) Stock Weight: 52 gsm to 260 gsm Collating Speed (A4): 3,500 Sets/Hr Error Detection: Miss, Double, and Jam Detection system (Photocell) Error Monitor: Two sets of Feed Error Monitors Power: 200 V 50/60Hz,220 V 60 Hz, 400 V 50 Hz Power Consumption: 200 V MC 80a 1,900 W, 400 V MC 80a 1,800 W / 200 V MC 80m 200 W, 400 V 200 W Machine Weight: MC 80a 229kg (505 lb) / MC 80m 223kg (492 lb) SPF-20 Stitcher & Folder Sheet Size: Max. 350(W) x 500(L) mm (13.7" x 19.6") Min. 120(W) x 180(L) mm (4.8" x 7.1") Finish Size: Max. 250(W) x 350(L) mm (9.8" x 13.7") Min. 90(W) x 120(L) mm (3.6" x 4.8") Stitching Thickness: Max. 4 mm (0.15") (only for side stitch) Stitching & Folding Thickness: Max. 2 mm (0.07") 20 sheets of 60 gsm Stitch Distance: 73 to 160 mm (2.9" to 6.2") Adjustable Stitching Wire: Standard: No. 25 (0.5 mm) (0.020") Option: No. 28 (0.4 mm) (0.016") Production Speed: Max. 3,660 booklets/hr. (A4-Finish) Max. 4,050 booklets/hr. (A5-Finish) Voltage / Frequency: Single Phase 200 V, 50 / 60 Hz Single Phase 220 V, 60 Hz Single Phase 230 V, 50 / 60 Hz Rated Current: Single Phase 200 V, 50 / 60 Hz, 3.7 / 2.9 A Single Phase 220 V, 60 Hz, 3.4 A Single Phase 230 V, 50 / 60 Hz, 2.2 / 2.0 A Power Consumption: Single Phase 200 V, 50 / 60 Hz, 460 / 400 W Single Phase 220 V, 60 Hz, 600 W Single Phase 230 V, 50 / 60 Hz, 520 / 500 W Heat Output: 620 kJ (150 kcal) Motors: 200 W x 1, 100 W x 1, 60 W x 1, 15 W x 1 Machine Weight: 1, 100 W x 1, 60 W x 1, 15 W x 1 470 kg (1,036.4 lbs.) FC-20 Fore-edge Trimmer Book Size (Before Trim): Max. 250(W) x 350(L) mm (9.8" x 13.7") Min. 90(W) x 120(L) mm (3.6" x 4.8") Finish Size: Max. 250(W) x 350(L) mm (9.8" x 13.7") Min. 85(W) x 120(L) mm (3.4" x 4.8") Trimming Length: Max. 20 mm (0.78") Trimming Thickness: Max. 4 mm (0.15") 50 sheets of 60 gsm Production Speed: 3,660 booklets/hr. (A4-Finish) 4,050 booklets/hr. (A5-Finish) Voltage / Frequency: Single Phase 200 V, 50 / 60 Hz Single Phase 220 V, 50 / 60 Hz Single Phase 230 V, 50 / 50 Hz Rated Current: Single Phase 200 V, 50 / 60 Hz, 1.5 / 1.6 A Single Phase 220 V, 50 / 60 Hz, 1.4 / 1.0 A Single Phase 230 V, 50 / 60 Hz, 1.3 / 1.4 A Power Consumption: Single Phase 200 V, 50 / 60 Hz, 290 W Single Phase 220 V, 50 / 60 Hz, 280 / 220 W Single Phase 230 V, 50 / 60 Hz, 270 / 300 W Motors: 400 W x 1, 60 W x 1, 25 W x 1 Machine Weight: 230 kg (507.2 lbs.) Good working order Available immediately Read more: https://www.jerrycurtin.com/machine/en-134466/horizon-mc-80-a,-mc-80-m,-spf-20,-fc-20-booklet-maker

The World of Print at your Fingertips

The Machine Dalal Mobile Apps

Download our Machine Dalal App Regular updates from our magazine with illustrations, innovations , commodities, history, media, art and a whole lot more from the magnificent world of Print.

Get the App

Login

Login