Sheet Lamination Machine - Friends

Sheet Lamination Machine - Friends

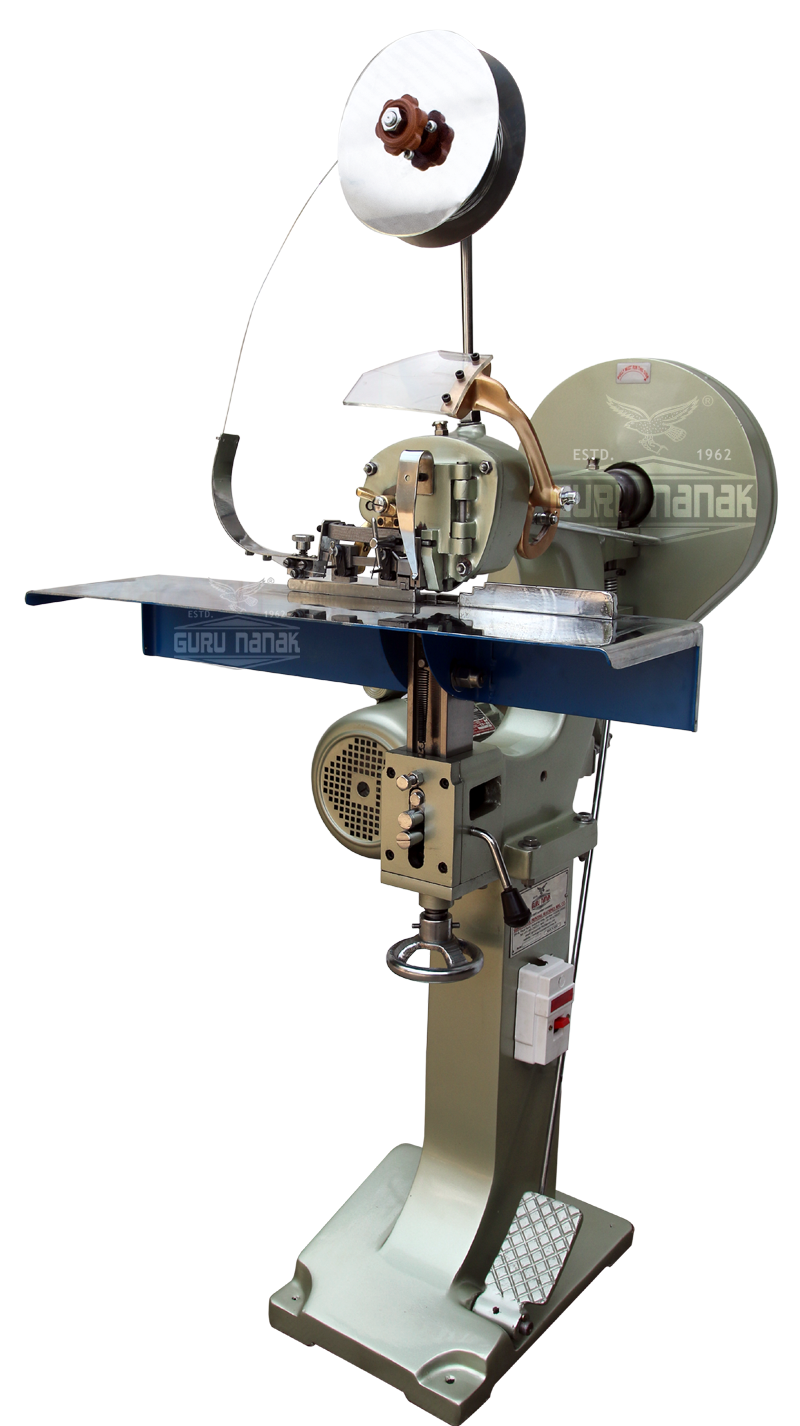

Machine Overview

Heavy Duty Sheet Lamination Machine. Lamination is the method thru which a sheet or roll is inserted separately into a conveyor kind Input bed of the Machine. A Transparent or Printed Lamination Film roll is constant by means of operator on the Lamination Roll gift within the Sheet Lamination Machine. With the assist of Gears and Motor, the Gum Rolls observe layer of Adhesive Solution on sheet and after which the Lamination film Roll is Stretched pressed against it to supply a laminated Output

The Graded Components Such as Multi Hardened Chrome Rolls, Heavy Durable En Graded Gears, All Weather Proof Gum Roll, Heavy Durable Anti Rusting gum tray are equipped in our Sheet Lamination Machine to provide magnificent output quality. The Variable Speed Drive, Electrical systems including Motor, Control and Operational Panel are assembled in the machine.

Features

| Plain/Hot and Cold Lamination Machine This is very commonly used Machine, where the gum tray is present to hold the bonding agent (gum) dissolved into a liquid (water or a solvent or a solution), is applied to one of the webs. The adhesive coated web is laminated to the other under strong pressure which improves the bond strength of the laminate. It is commonly used to produce a Duplex sheets / paper-aluminum foil laminate that are widely used in flexible packaging. INPUT: SHEET FORM OUTPUT: ROLL FORM |

| Roll to Roll Lamination Machine For the purpose such as Paper Plate Lamination Roll Making, Kraft BOPP Roll Lamination Making, When Cold or Plain Lamination Machine is attached with a Special Roll winding Mechanism along with the Roll Stand to allow the operator have optional to Insert the Input in sheet or Roll Form. INPUT: SHEET / ROLL FORM OUTPUT: ROLL FORM |

| Window cum Plain Lamination Machine This Special Dual Machine is used for Window type Lamination along with Cold / Plain Lamination. Any box with a window or open cut out of any shape can be laminated through this Machine only like Garments see through boxes, Sweet Boxes, Dry Fruit Boxes, Fancy Packaging Boxes, etc. This Machine Scrap out the Excess Gum and make a successful see through laminated sheet. INPUT: SHEET FORM OUTPUT: ROLL FORM |

Technical Specifications

| Size | 26" (660 mm) |

| Max. Laminating Width | 660 mm x any length |

| Speed | 0-600 mt. /Hr. |

| Max. Film Roll Width | 660 mm |

| Max. Film Roll Diameter | 305 mm |

| Power Required 220V D.C. Motor | 0.8 KW |

Easy Financing with Machine Dalal

Business and Machinery Loans available for this model.

Apply in minutes. Get approved fast. Flexible loan options to power your machinery purchase.

Apply Nowtrending_flatGrow Your Machinery Sales

More Exposure. More Leads. More Machinery and Equipment Sales. Reach more Printers, Publishers and Packaging Manufacturers with Machine Dalal.Follow the link to explore Enterprise Services.

Learn Moretrending_flat

Keep Exploring

Speedmaster SM 74-4 H

Sheet Fed / Offset

ZSSY

TB22

Banding Machine

Banding machines or bundling machines strap products with bands made of kraft paper or film. The banding machine heat-welds the film band or the one-sided plastic-coated bundle material. It processes bands in widths from 20 to 22 mm. The triggering is automatic via a sensor, manually, or via the included foot switch.

The World of Print at your Fingertips

The Machine Dalal Mobile Apps

Download our Machine Dalal App Regular updates from our magazine with illustrations, innovations , commodities, history, media, art and a whole lot more from the magnificent world of Print.

Get the App

Login

Login