Die Punching Machine - Friends

Die Punching Machine - Friends

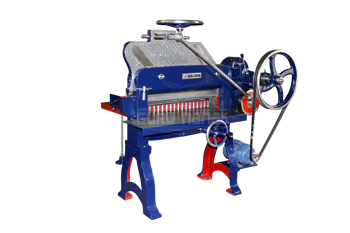

Machine Overview

"Friends' Brand Die Punching Machine and Heavy Duty Platen Punching Machine" is intended for die cutting, creasing, and embossing on paper, cardboard, corrugated board, leather, plastic, and pvc, among other materials.

We design our premium Friends complete heavy duty die punching machine with an electro-magnetic clutch and brake for performing all simple and straightforward operations. This Die Punching Machine is capable and designed basically for performing Die-Cutting, Creasing, Punching, and Embossing Job on various merchandise like Paper, Cardboard, Fibre Board, Vinyl, Foam, Rubber, Leather, Masonite, Cork Sheets, affixed Boxes, Advertising Cut out, Jigsaw Puzzles, Labels, and far more.

Features

| Completely standardised where all elements can be interchangeable. |

| All shafts are made of EN Grade metal, the pins are grounded, and the trees are made of Phosphorus Bronze Alloy. |

| All bearings are of the highest quality from SKF/NBC/NACHI. |

| Machine with fail-safe combination clutch brakes and adjustable machine. |

| The main driving shaft is equipped with double helical self-lubricated imported polyamide/metal pinion units. |

| The main electric powered panel that includes all operation and management functions, is outfitted with a Detachable Socket System and international standardised additives such as Siemens/L&T/Schneider (France) and so on. |

| Software for self-diagnosis with visual indicators. |

| The main flywheel is secured with a check-nut machine, and a fully automatic centralised lubrication system is provided. |

| A fully automatic centralised lubrication system is provided. |

| Fast and Easy adjustment of impressions via worm gears and eccentric bushes within the cam for left-proper and up-down of platen to make the four corners equal. |

| Machine is having quite silent walking and outlook is wonderful with nice paint and powder lined fitting. |

| “Friends” Fastest Platen commencing 87” to provide press Operator Increased Time to feed turning in extra productivity. |

Technical Specifications

| Platen Size (in) | 22×28 |

| Inside Chase (in) | 20×26 |

| Platen Size (cm) | 56×71 |

| Inside Chase (cm) | 51 x 66 |

Application

Paper, Cardboard, Fibre Board, Vinyl, Foam, Rubber, Leather, Masonite, Cork Sheets, affixed Boxes, Advertising Cut out, Jigsaw Puzzles, Labels, and far more.

Easy Financing with Machine Dalal

Business and Machinery Loans available for this model.

Apply in minutes. Get approved fast. Flexible loan options to power your machinery purchase.

Apply Nowtrending_flatGrow Your Machinery Sales

More Exposure. More Leads. More Machinery and Equipment Sales. Reach more Printers, Publishers and Packaging Manufacturers with Machine Dalal.Follow the link to explore Enterprise Services.

Learn Moretrending_flat

Keep Exploring

CAS 52‑0‑4‑40‑SL

Folding Machine

Mobile single folding unit Bäuerle CAS 52-0-4-40-SL with self-control from 2008

M 300

Commercial / Heatset

1 EnkIe double Roll Splicer 1 HARRIS Infeed Unit 1 E & L web guide 4 HARRIS Printing Units Alcohol Film Dampening Refrigeration Unit Ink Unit Temperature control 2 Operator consoles Main and auxiliary command 1 QTI automatic color registration control system 1 QTI cut control 1 Band break detection package 1 Main press drive system 1 TEC Dryer 1 HARRIS Chill Rolls, 4-Rolls 1 Silicone Applicator 1 Folder superstructure with 4 angle bars Former Fold and perforation- and Slitter bars 1 HARRIS JF-44 combination folder 1 Sheeter

The World of Print at your Fingertips

The Machine Dalal Mobile Apps

Download our Machine Dalal App Regular updates from our magazine with illustrations, innovations , commodities, history, media, art and a whole lot more from the magnificent world of Print.

Get the App

Login

Login