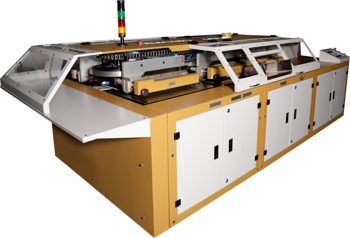

Automatic Die Cutting and Creasing Machine - Friends

Automatic Die Cutting and Creasing Machine - Friends

Machine Overview

Features

| Totally standardized (i.e. all components square measure inter-changeable) |

| All shafts measure from linear unit Grade steel and pins measure grounded & bushes from Phosphorus Bronze Alloy. |

| All bearings measure of SKF/NBC/NACHI solely. |

| Fail-safe combination clutch brakes machine with adjustable machine (up to microns). |

| The major driving shaft is ready with units of double helical self-lubricated imported polyamide/metal pinion. |

| Self diagnostic gadget software with visual indications. |

| The main electric powered panel (operation and management) is outfitted with a Detachable Socket System and international standardised additives such as Siemens/L&T/Schneider (France) and among others. |

| Main flywheel is locked with check-nut machine. |

| Fully Automatic Centralized Lubrication System is provided. |

| Easy adjustable features of impressions is created through 2 worm gears and eccentric bushes within the cam for left-right and up-down of platen to make the four corners equal. |

| Machine has quite silent running and outlook is great with very best quality paint and powder coated fitting. |

| “Friends” quickest Platen Opening 87” to supply press Operator adequate Time to feed delivering more productivity. |

| All of the characteristics that render the "Friends" Platen Punching Machine the most reliable and maintenance free equipment |

Technical Specifications

| Platen Size (in) | 22×28 |

| Inside Chase (in) | 20×26 |

| Platen Size (cm) | 56×71 |

Easy Financing with Machine Dalal

Business and Machinery Loans available for this model.

Apply in minutes. Get approved fast. Flexible loan options to power your machinery purchase.

Apply Nowtrending_flatGrow Your Machinery Sales

More Exposure. More Leads. More Machinery and Equipment Sales. Reach more Printers, Publishers and Packaging Manufacturers with Machine Dalal.Follow the link to explore Enterprise Services.

Learn Moretrending_flat

Keep Exploring

SP 102 Evoline

Die cutting

XQQK

HSW P9

Poly Wrap Mailing Machines

The Norpak HSW P9 Poly Wrap Machine is a high-speed poly wrapping solution designed for efficient packaging of printed materials such as books, magazines, and catalogs. This machine is ideal for high-volume mailroom operations requiring rapid and secure wrapping of items. Mechanical Speed: Up to 9,000 packs per hour Film Type: Polyethylene Film Roll Width: Up to 550 mm Film Thickness: Up to 120 µm Power Supply: 400V, 50-60Hz Dimensions: Approximately 2160 mm (L) x 1340 mm (W) x 2000 mm (H) Weight: Net weight around 570 kg; gross weight approximately 620 kg Ideal for use in publishing houses, direct mail companies, and e-commerce fulfillment centers, the Norpak HSW P9 Poly Wrap Machine is perfect for efficiently wrapping and mailing printed materials.

The World of Print at your Fingertips

The Machine Dalal Mobile Apps

Download our Machine Dalal App Regular updates from our magazine with illustrations, innovations , commodities, history, media, art and a whole lot more from the magnificent world of Print.

Get the App

Login

Login