Auto Feed Die Cutting Machine - Friends

Auto Feed Die Cutting Machine - Friends

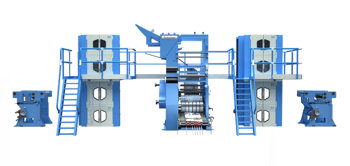

Machine Overview

The machine is equipped with multiple electric eye checks to reduce paper waste. The delivery table is equipped with an automatic support device. Precisely, safe and easy to operate.

The front block and side block can be adjusted freely by the paper size. Easy to adjust and precisely. The collection and delivery table both adopt the vacuum inspiration to avoid the problem of the gripper biting no paper.

The device applies to common paperboard, e/b/a corrugated paper, and plastic board. The collection table & delivery table are equipped with automatic support devices. Continuous operation without stopping, works efficiently.

The feeder part is equipped with a tracking device, separating freely when you make a plate. The product has the advantages of low maintenance cost, high speed, convenient operation, saving labor costs, and accurate paper feeding.

Features

| aper feeding unit with Safety Guard System: This unit is mainly used to Feed the sheets into the System. The suction head collect the Sheet from the Bunch and precisely shift the sheet into the conveyor System. The safety guardrail encloses the machine’s paper feeding work area to prevent personnel from entering the danger zone. |

| Conveyor Belt With Roller System This Unit is Equipped with High Wear Resistant paper Pressing Rubber Wheels & Wool Wheels Which can easily Adjust the Pressure, so as to ensure the Paper is Smoothly Transported to the Front Specified Position, Preventing the Collision of Sheets. |

| Paper Replacement unit with Vacuum pump This Unit Lift the Punched Sheet from the Machine and feed the New Sheet into the Die Cutting Machine smoothly with the help of the Pneumatic Suction Head and High wear resistant Rubber and Wool Rollers. |

| Paper Output unit All the Output Sheets Discharged From Die Punching Machine is stacked into the Tray which can be Easily Collected out. This Units is Equipped with Multi Protection Safety System to ensure Neat and Orderly collection of Sheets. |

Technical Specifications

| PLC control speed | Medium |

Easy Financing with Machine Dalal

Business and Machinery Loans available for this model.

Apply in minutes. Get approved fast. Flexible loan options to power your machinery purchase.

Apply Nowtrending_flatGrow Your Machinery Sales

More Exposure. More Leads. More Machinery and Equipment Sales. Reach more Printers, Publishers and Packaging Manufacturers with Machine Dalal.Follow the link to explore Enterprise Services.

Learn Moretrending_flat

The World of Print at your Fingertips

The Machine Dalal Mobile Apps

Download our Machine Dalal App Regular updates from our magazine with illustrations, innovations , commodities, history, media, art and a whole lot more from the magnificent world of Print.

Get the App

Login

Login