Oblique Type Corrugation Machine - Friends

Oblique Type Corrugation Machine - Friends

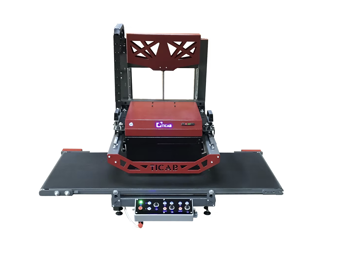

Machine Overview

The oblique corrugation machine is equipped with a massive motorised roll stand capable of lifting a 2-ton roll at a time. It provides smooth functionality and dependable performance due to the flute rollers mounted on bearings. This oblique corrugation machine is commonly used to convert paper into two-ply corrugated rolls.

Features

| Building and operation Bearings are enabled with rollers. |

| delivered with pre-heaters asunder from the three regular heaters tode-moisturize the liner |

| Equipped with binary shaft motorized tone lading roll stand & bull |

| Construction, operation, and bulldozing, The flute breakers are mounted on bearings for smooth operation and extended life. |

| The flute breakers are made of special amalgamation sword & bull |

| The main bearing are waxed with high temperature grease |

| It is enabled by gum Hard chromed rollers for improved performance and machine life |

| Two pre-heaters are provided to de-moisturize the paper. |

| A variable speed motor is recommended for improved quality and frugality in destruction at a lower cost. |

| Capacity to lift up to 1 ton roll |

| This model includes a variable drive motor as standard. |

| Handed with' Goliath' type motorized Hydraulic roll stage. |

Technical Specifications

| Sizes(Inches) | 42" |

| Heating Load (Approx.)in KW | 21 |

| Power (H.P) | 3 |

Easy Financing with Machine Dalal

Business and Machinery Loans available for this model.

Apply in minutes. Get approved fast. Flexible loan options to power your machinery purchase.

Apply Nowtrending_flatGrow Your Machinery Sales

More Exposure. More Leads. More Machinery and Equipment Sales. Reach more Printers, Publishers and Packaging Manufacturers with Machine Dalal.Follow the link to explore Enterprise Services.

Learn Moretrending_flat

Keep Exploring

Pegasus Semi automated Laminator

Laminating and coating

We are pleased to offer: Used D&K PEGASUS Semi-automated Laminator Year 2010 Specification Category: Laminating machine This is an entry-level addition to the D & K family of production laminators. A belt-driven infeed enables prints up to B2 to be presented to the lamination section, making it suitable for thin, economic laminates. The integral burster makes low- to medium-volume laminating truly a one-man operation. An automatic feeder is now available to increase the Pegasus's productivity; it can be retrofitted to grow with your needs. Good working order Available immediately Read more: https://www.jerrycurtin.com/machine/en-134495/dandk-group-pegasus-semi-automated-laminator

CD 74-4C

Sheet Fed / Offset

ZSLA

The World of Print at your Fingertips

The Machine Dalal Mobile Apps

Download our Machine Dalal App Regular updates from our magazine with illustrations, innovations , commodities, history, media, art and a whole lot more from the magnificent world of Print.

Get the App

Login

Login