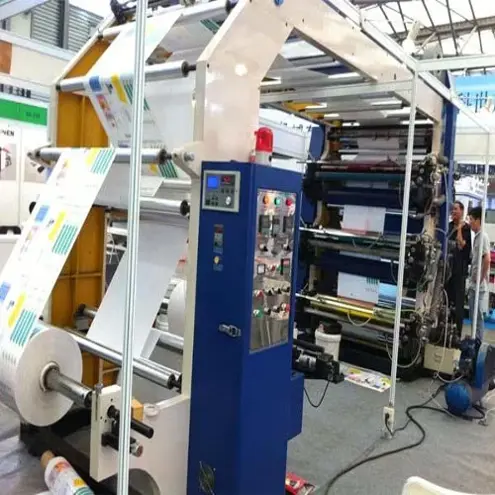

6 Colour Flexo Printing - Happy

6 Colour Flexo Printing - Happy

Machine Overview

Features

| Trouble free performance |

| Enhanced service life |

| Precisely-designed |

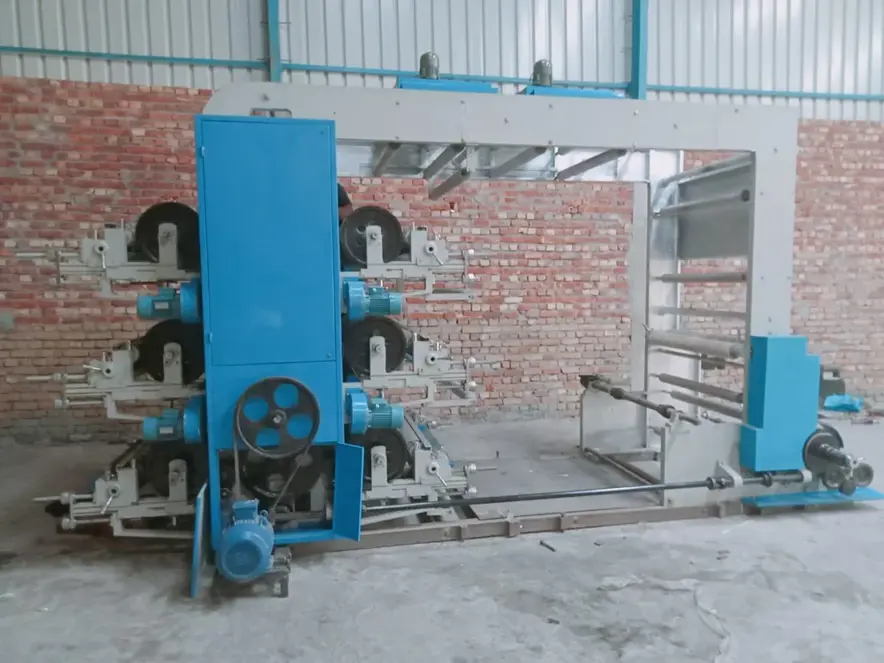

| Unwinder |

| Unwind type- Single fixed shaft type or 2 shaft turret type unwinder |

| Rewinder- 1000 mm |

| Unwind shaft - Manual & Air shaft, tapper cone with solid shaft or shaft ness |

| Tension controller - Manual & Fully automatic control system (A.C. & D.C. motor) |

| Printing Unit- |

| Frame- Iron cast |

| Cylinder- 10" to 50" repeat |

| Chucking- Shaft with taper cone, one roll arm with pneumatic pressure system |

| Drying system- Each station half H.P. blower & two exhaust fan for perfect drawing |

| Ink system- Long & deep tray for fabric ait by steel |

| Rewind type- Single fixed shaft type or 2 shaft turret type |

| Rewinder- 1000 mm |

| Rewind shaft- Manual & air shaft tapper cone with solid shaft or shaftness |

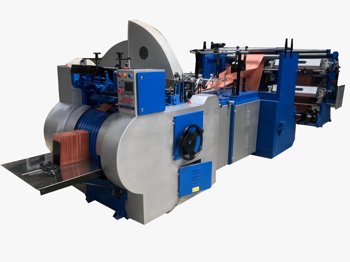

Technical Specifications

| Web substrate | Film, paper, HDPE, poly, non woven, non- woven fabric, woven sack |

| Min Web width | 20 inch |

| Max Web width | 62 inch |

| Web roller | Aluminum rollers or steel rollers |

Easy Financing with Machine Dalal

Business and Machinery Loans available for this model.

Apply in minutes. Get approved fast. Flexible loan options to power your machinery purchase.

Apply Nowtrending_flatGrow Your Machinery Sales

More Exposure. More Leads. More Machinery and Equipment Sales. Reach more Printers, Publishers and Packaging Manufacturers with Machine Dalal.Follow the link to explore Enterprise Services.

Learn Moretrending_flat

Keep Exploring

Combi 340

Letterpress

Unwinding Web cleaning 6 letterpress units 1 UV flexo unit 7 GEW UV drying units Rotary die cutting unit BST register camera Slitting Rewinding Servo drives B&R replaced in 2013

AFC-504AKT

Folding Machine

max. size 49 x 65 cm age 2000 flat pile feeder with suction head 4 folding pockets in the parallel fold section 1 folding knife in the cross fold section 1 additional folding pocket after the 1st cross fold stream delivery Delivery time: shortly Ref: HO250024A Please ask for price. We ship and install worldwide!

The World of Print at your Fingertips

The Machine Dalal Mobile Apps

Download our Machine Dalal App Regular updates from our magazine with illustrations, innovations , commodities, history, media, art and a whole lot more from the magnificent world of Print.

Get the App

Login

Login