Laminators - Kosbridge

Laminators - Kosbridge

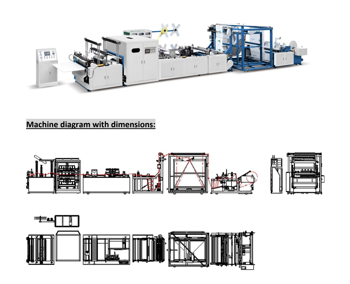

Machine Overview

This machine is suitable for laminating plastic-plastic

and aluminum foils and other laminated

materials in the packing industry.

About Machine

This machine is suitable for laminating plastic-plastic

and aluminum foils and other laminated

materials in the packing industry.

Features

| The machine adopt variable frequency speed regulating motor transmission. |

| 1st unwinding adopts single station, with EPC system, magnetic powder brake control |

| tension. |

| 2nd unwinding adopts single station, unwinding adopts magnetic powder brake |

| control tension. |

| Coating unit adopt anilox with doctor blade, the doctor blade can be adjusted with three positions. |

| Three section pneumatic lifting constant temperature oven, Divided layer of the inlet and outlet air adopt negative pressure design, return air twice. |

| It can both saving energy and also reduce the residual solvent content. |

| Laminating pressure roller and coating pressure roller both adopt double air cylinder. |

| Rewinding adopts torque motor |

Technical Specifications

| Unwinding adopts | Single station |

Easy Financing with Machine Dalal

Business and Machinery Loans available for this model.

Apply in minutes. Get approved fast. Flexible loan options to power your machinery purchase.

Apply Nowtrending_flatGrow Your Machinery Sales

More Exposure. More Leads. More Machinery and Equipment Sales. Reach more Printers, Publishers and Packaging Manufacturers with Machine Dalal.Follow the link to explore Enterprise Services.

Learn Moretrending_flat

Models

Keep Exploring

Speedmaster SM 74-4 H

Sheet Fed / Offset

ZSZG

T 36.4/KB

Folding Machine

Falzmaschine - Folding Machine Stahl T 36.4/KB Baujahr / Year 1989 - Serial-No. 30335-118047 Flachstapelanleger / Flat Pile Feeder Falztyp: 4 Taschen - Schwert Folding Type: 4 buckles - 1 knife Format / Size: min. 80 x 100mm - max. 360 x 650mm Papiergrammatur / Paper weight: 40 – 250g/m² Stapelhöhe / Pile height max. 580mm Geschwindigkeit / Speed min. 10 m/min. - max. 160m/min. Durchmesser Falzwalzen / Diameter of folding rollers 32mm Auslage Schuppenauslage / Delivery Stream Delivery Kompressor / Compressor include - Manuals Included

The World of Print at your Fingertips

The Machine Dalal Mobile Apps

Download our Machine Dalal App Regular updates from our magazine with illustrations, innovations , commodities, history, media, art and a whole lot more from the magnificent world of Print.

Get the App

Login

Login