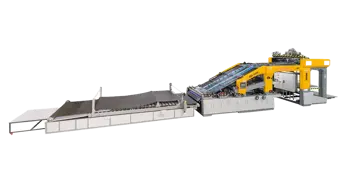

Roll to Roll Flexographic Printing Machine Without Change Cylinder - Multiplast

Roll to Roll Flexographic Printing Machine Without Change Cylinder - Multiplast

Machine Overview

Features

| With web guiding device to control edge position |

| Fully digitalized control setting on friendly human machine interface(HMI) |

| Full body cover |

| Machine power on and off controlled by HMI |

| Double side dried by automatic constant temperature oven. |

| Automatic feeding |

| One time printing on two sides, accurate colour registration. |

| PLC centralized control touch screen to set bag length. |

| Colour mark tracking is suitable for reserve printing printed woven bags |

| Start up with smook ink automatically |

| Press printing without automatic clutch, no defective products when machine turn on or shutdown |

| Frequency conversion control unwinding and unwinding part. |

| Machine power on or and off is controlled by remote-control Unit |

| This machine is applied for solvent- based ink and direct printing method for PP woven bag with / without lamination, available for CMYK colour combination to obtain realistic printing quality enhance packing valve. |

Technical Specifications

| Fabric Width Max | 36" / 914.40 mm |

| Repeat Length (max) | 32" / 863.60 mm |

| Print Width Max | Minimum 3mm, Maximum 8mm |

| Stereo (photopolymar Plate) Thickness | 60/70 Bags Per Min |

Application

PP / HDPE Bags Laminated and Unlaminated Fabrics

One Side Pre-Printed BOPP Bags

Fertilizer Bags

Cement / Sugar Bags

Easy Financing with Machine Dalal

Business and Machinery Loans available for this model.

Apply in minutes. Get approved fast. Flexible loan options to power your machinery purchase.

Apply Nowtrending_flatGrow Your Machinery Sales

More Exposure. More Leads. More Machinery and Equipment Sales. Reach more Printers, Publishers and Packaging Manufacturers with Machine Dalal.Follow the link to explore Enterprise Services.

Learn Moretrending_flat

The World of Print at your Fingertips

The Machine Dalal Mobile Apps

Download our Machine Dalal App Regular updates from our magazine with illustrations, innovations , commodities, history, media, art and a whole lot more from the magnificent world of Print.

Get the App

Login

Login