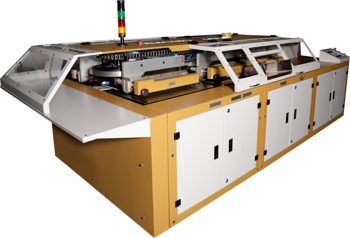

Mini Offset Printing Machine - BPL

Start a Conversation mark_unread_chat_alt

Mini Offset Printing Machine - BPL

Connect trending_flat

close

Machine Overview

Features

| Three main hard chromium-faced cylinders strongly guarantee their resistance & durability. |

| Bearing type pull side lay with micro adjustment without stopping the machine. |

| Chain delivery with three gripper bars. |

| Front plate loading system. |

| Single lever operation for dampening, Inking & Impression. |

| Vertical micro adjustment on plate cylinder. |

| Compact & stable structure. |

| Reverse and forward Inching. |

| Skip feed function is realizable to ensure ink density. |

| Centralized oil lubrication system. |

| Pre-set copy counter & digital speed indication. |

| Jogger system to collect the bag & paper on delivery. |

| No sheet detector. |

| Speed set plate clamp. |

| Multi sucker universal feeder. |

| Shorter Make-Ready-Time. |

| Print with poly master & plates. |

Technical Specifications

| Max. Size | 280x380mm(11"X15") |

| Max. Printing Area | 280x350mm |

| Min. Size | 125x180mm |

| Plate Size | 280x395mm |

| Blanket Size | 280×420 |

| Paper Thickness | 30-300gms |

| Ink Roller System | 11(2 form) Rollers |

| Water Roller System | 4 (1 form) Rollers |

Easy Financing with Machine Dalal

Business and Machinery Loans available for this model.

Apply in minutes. Get approved fast. Flexible loan options to power your machinery purchase.

Apply Nowtrending_flatGrow Your Machinery Sales

More Exposure. More Leads. More Machinery and Equipment Sales. Reach more Printers, Publishers and Packaging Manufacturers with Machine Dalal.Follow the link to explore Enterprise Services.

Learn Moretrending_flat

The World of Print at your Fingertips

The Machine Dalal Mobile Apps

Download our Machine Dalal App Regular updates from our magazine with illustrations, innovations , commodities, history, media, art and a whole lot more from the magnificent world of Print.

Get the App

Login

Login