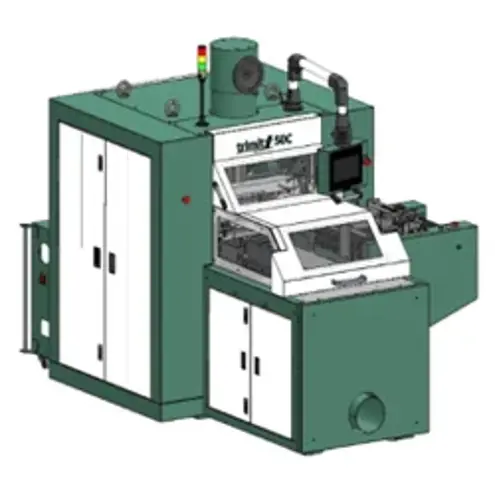

Trimit 50C Three Knife Trimming Machine - Bindwel Technology

Trimit 50C Three Knife Trimming Machine - Bindwel Technology

Machine Overview

Features

| Trimit 50C, a remarkable device equipped with advanced technology. |

| Automatic, high speed three knife trimmer, following international safety standards. |

Technical Specifications

| Automation Grade | Automatic |

| Production Capacity | 3000 Cycles per hour |

| Frequency | 50 Hz |

| Max Thickness | 100 mm |

| Voltage | 415 V |

Easy Financing with Machine Dalal

Business and Machinery Loans available for this model.

Apply in minutes. Get approved fast. Flexible loan options to power your machinery purchase.

Apply Nowtrending_flatGrow Your Machinery Sales

More Exposure. More Leads. More Machinery and Equipment Sales. Reach more Printers, Publishers and Packaging Manufacturers with Machine Dalal.Follow the link to explore Enterprise Services.

Learn Moretrending_flat

Keep Exploring

Indigo 5500

Digital Press

Digitaldruckmaschine - Digital Printing Machine HP Indigo 5500 Year 2007- Serial-No. 30005331 Printing speed 68 4-color 8.5 x 11 in images per minute (two-up); 136 2-color and 8.5 x 11 in images per minute (two-up) Image resolution 812 dpi at 8 bit, 812 x 1624 dpi in High Definition Imaging Line screens 144, 160, 175, 180, 230 lpi Paper format 13 x 19 in maximum Image format 12.12 x 17.7 in Paper weight* Coated: 55 lb text - 130 lb; Uncoated: 40 lb text - 120 lb; Thickness: 3-16 pt Paper input system • Two drawers with 7 in depth each each (1800 sheets of 3-16 pt) • A total of 3600 sheets of 80 lb. text. • All paper drawers support the full range of substrates Paper output system • Autoduplex/autoperfecting standard • Main stacking tray with 23.6 in stack height with job offset stacking (6000 sheets of 80 lb text) • Proof tray with 2.36 in stack height (600 sheets of 18 lb text)

TYMB 1100

Die cutting

ZWYO

The World of Print at your Fingertips

The Machine Dalal Mobile Apps

Download our Machine Dalal App Regular updates from our magazine with illustrations, innovations , commodities, history, media, art and a whole lot more from the magnificent world of Print.

Get the App

Login

Login