Bindwel BW2500 Six Clamp Perfect Binding Machine - Bindwel Technology

Bindwel BW2500 Six Clamp Perfect Binding Machine - Bindwel Technology

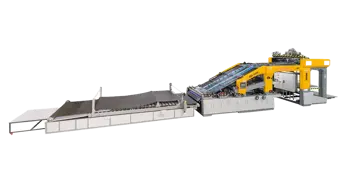

Machine Overview

High quality bookbinding with improved notching, accurate temperature control, 3 Roller spine gluing, driven side glue, adjustable cover creasing and powerful cover nipping

Built in Intelligent MIS system providing complete production data

More options than before for increased productivity and for continuous cost-efficiency

Features

| 6 Clamp Perfect Binder Perfect Binder EPIC model More Efficient, Productive, Intelligent and Cost effective |

| • High quality bookbinding with improved notching, accurate temperature control, 3 Roller spine gluing, driven side glue, adjustable cover creasing and powerful cover nipping. • Built in Intelligent MIS system providing complete production data. • More options than before for increased productivity and for continuous cost-efficiency. |

| Control system with a smart-HMI that provides all the information on settings, production and help improve efficiency Safety covers and systems for protection |

| 6 book clamps travelling in an oval shaped path, where the spine is in line with the crucial binding station |

| Calibrated book clamps with thickness indicators; single knob adjustments. Easy job change over |

| Continuous flow of clamps to the feed-in station with “No book-No cover” system |

| Special type milling cutter which removes paper in “strips” form (which has commercial value) and avoids generation of paper dust. (Optional dust collector system) |

| Three roller gluing system with reverse spinner; calibrated head & tail end cut-offs to avoid adhesive squeeze out (mechanical and pneumatic options) |

| Separate side gluing station with tank & gluing discs. A thin & even layer of glue is spread along the side adding value to the book finish |

| Automatic, pile type cover feeder with adjustable and ornamental creasing attachment. |

| Pre-pasting station and moving type Cam based cover nipping station which can handle high speeds with accurate cover registration |

| Chute delivery system |

Technical Specifications

| Max Binding Thickness | 50 mm |

| Machine Type | Glue Binding - Adhesive Binding |

| Automation Grade | Automatic |

| Voltage | 415 V |

| Min Book Size | 150 mm x 100 mm |

| Min Cover Size | 150 mm x 220 mm |

| Production Capacity | 2500 Books Per Hour |

| Max Cover Size | 440 mm x 510 mm |

| Max Book Size | 440 mm x 230 mm |

Easy Financing with Machine Dalal

Business and Machinery Loans available for this model.

Apply in minutes. Get approved fast. Flexible loan options to power your machinery purchase.

Apply Nowtrending_flatGrow Your Machinery Sales

More Exposure. More Leads. More Machinery and Equipment Sales. Reach more Printers, Publishers and Packaging Manufacturers with Machine Dalal.Follow the link to explore Enterprise Services.

Learn Moretrending_flat

Keep Exploring

SM52-4S

Sheet Fed / Offset

ZAPA

eFlex 330-2 S

Flexographic equipment

Full Servo Drive Technology EFLEX 330 – 2 S & helical gearing 8 Colour + Extended Die Module 2 x Die + Sheeter 8 X Lamp IR & Hot Air Drying Systems 8 x Lamp UV System + Chill Rolls & Chiller 2nd Pass Upgrade – Unwind Roll Lift Corona - Single Sided (2 Kw) Web Cleaner (2 Sided) with anti static Rail System Turn Bar with Delam-Relam (Rail mounted) Cold Foil (Rail Mounted) Sheet Stacker (Shingle Conveyor) Peel & Reveal Tint roll with air mandrel Antistatic unit 4 bars Rotary die adaptors (1 Set) Edge trim extraction (Venturi) - requires air supply Reverse rewind Video Inspection System (double side viewing E + L) FOCUS Video Plate mounter Platemate Upgrade Full Length Rail Rail Mounted Snow Ball Waste Rewind Web width: 330 mm Minimum printing length: 180 mm Maximum printing length: 510 mm Material thickness: 18 microns to 280 g/m² Pre-Register Autoregister Servo drive 2 per print head UNWIND MODULE: 1000 mm diameter capacity high performance air core 76mm (Lug type leaves) Servo braking system (closed loop) automatic tension adjustment Automatic web guide splice guide with automatic paper clamps, Operator control panel End of Roll detection (Options to add corona treater, web cleaning systems) INFEED ROLL: Servo drive with nip roll (closed loop tension control) FLEXO PRINTING MODULES: HMI (touch screen operator interface) 28 D.P / 1/8” helical gearing Servo driven impression roll Independent servo driven anilox roll & print cylinder Pre-register set up functions. Auto-register Cartridge based inking units Ink fountain tray with integral metering roll, doctor blades & side wipers. On run lateral & linear register adjustment Automatic plate throw off & constant anilox rotation INFRA-RED: Individual Eco-control dryers with variable 0 - 2Kw infrared lamps and forced air over substrate, plus progressive temperature increase with press speed & waste air vacuum / extraction SLITTING UNIT 2 x slitting unit - supplied with 5 x pneumatic crush slitters. (additional slitters optional) ROTARY DIE / SHEETER MODULE: 2 x Independent servo driven die station 1 x Independent servo driven die / sheeter station Each die unit is independently driven & equipped with heavy duty anvil roll Removable anvil for reverse cutting applications Lateral & linear manual register adjustment. WASTE REWIND TURRET: Servo driven rail mounted REWIND MODULE Direct torque motor drive Suitable for film to board products High performance air core Core 76mm (Lug type leaves) Roll Break detection Inside or outside rolls option Maximum reel diameter: 800 mm HMI OPERATOR CONTROLS: MAIN PLC touch-screen Operator Control Interface, with predetermined count, press speed, Emergency Stop, Rewind tension adjustment. Dryer controls, Pre-register, Data storage for job, materials, speeds, drying settings. Diagnostics error display system for easy problem solving. Focus remote service & support diagnosis

The World of Print at your Fingertips

The Machine Dalal Mobile Apps

Download our Machine Dalal App Regular updates from our magazine with illustrations, innovations , commodities, history, media, art and a whole lot more from the magnificent world of Print.

Get the App

Login

Login