Popular Brands Or view all

Sheet Fed / Offset Machinery for Sale | Preowned & Preloved

Ryobi

522

1996

Sheet Fed / Offset

We are pleased to offer: Used RYOBI 522 - Two-Colour Offset Press Year 1996 Specification The RYOBI 522 is a reliable two-colour sheetfed offset press designed for medium-run commercial printing. Manufactured in 1996, this model is well known for its solid Japanese engineering, consistent print quality and straightforward operation. Equipped with a continuous dampening system (Ryobimatic) and supported by a Technotrans refrigeration and recirculation unit, the press ensures stable ink-water balance and temperature control during production. It is ideal for commercial print shops producing brochures, stationery, flyers and general B3-format work. Sheetfed offset press 2 printing units (two colours) Maximum sheet size: 520 × 365 mm Minimum sheet size: 100 × 150 mm Maximum printing area: 505 × 350 mm Up to 13,000 sheets per hour (depending on stock and job) Paper thickness: 0.04 – 0.50 mm Suitable for light paper up to light board Dampening System: Continuous dampening (Ryobimatic type) Technotrans cooling and circulation unit Weight: Approx. 3,400 kg Good working order Available immediately

2

Hampshire United Kingdom

United Kingdom

KBA

RA 76-8-P

2022

Sheet Fed / Offset

Eight Color with Perfectin Format max.: 530 X 750 mm Format min.: 210 X 297 mm Image area: 520 X 740 mm Stock thickness: 0,04 - 0,6 mm Pile Height Feeder: 1200 mm Pile Height Delivery: 1360 mm Speed max.: 16.000 s/h Impression Count: 57 MIO. Specification: Drive Tronic Feeder ColorTronic - Press control ErgoTronic control console QualiControl Densitometer Wallscreen ErgoTronic Color Drive ErgoTronic ACR (Automatic Camera Register) FAPC Full automatic Plate Changer ErgoTronic automatic make ready CleanTronic - Syncron all automatic washing devices Vari Damp alcohol dampening TECHNOTRANS Combi Refrigeration Unit Ink Unit Temperature control Air Tronic Delivery Powder Spray Performance Package SIS

8

Oslo Norway

NorwayMCID_165

Heidelberg

Speedmaster SM CD 102-6 LX

2000

Sheet Fed / Offset

HEIDELBERG CD102-6L - 6 Printing Units + 1 Coating Unit - Year – 2000 - Impressions 210 million (Now counter is showing 0) - Straight Printing Press TECHNICAL SPECIFICATION - Speed 15.000 sheet/h - Max paper size 720 x 1020 mm (28” x40”) - Printable Stock Thickness – 0.03mm – 0.8mm PRESS CONFIGURATION / FEATURES INCLUDED 1. PRESS CONTROL - CP 2000 centre with touch screen - Remote ink control with main and fine ink display - Remote register control (Diagonal, Lateral and Circumferential) - Remote Pressure control - CIP3 Connectivity Support - Job saving and memory Management - Service Diagnosis - Day light illuminator and cassette or memory card for job memories - Sample sheer holder 2. FEEDER UNIT - Preset Feeder - Stream feeder - Non-Stop feeder with ramps - Display for monitoring sheet travel - Automatic Format setting - Stream feeder with belt - Electronic double sheet detection - Electro mechanic double sheet detection - Electronic side lay control, - Anti-static on feeder - Automatic sheet arrival control - Automatic Front lay control - With sheet deposit on the feeder - Rear edge blowers 3. PRINTING UNIT - Auto Plate with 0.15mm under cut - 3 IST UV lamps + 3 End of press - Trible Diameter transfer cylinders - Double Diameter impression cylinders - Chrome Cylinders - Steel Grippers - Air control between cylinders to ensure smooth sheet travel - Blanket cylinder for mounting blanket with metal edged - Plate cylinder circumferential adjustment - Auto blanket wash with programmable system - Remote Oscillation roller timing adjustment for gripper to tail colour variation - Alcolor dampening system with Vario system - Technotrans with Combination device – Alcohol Free 4. DELIVERY UNIT - Preset Delivery - Extended delivery – X3 - High Pile Delivery - Preset Delivery control - Preset Format setting - Powder spray system - Sheet de-curler - Air blower control - Delivery fans to ensure proper filing - Sheet guidance with cooled guide plate - Sheet slow down device with 10mm suction drum - Narrow supporting roller between the suction rollers 5. COATING UNIT - Two roller coating system with chambered blade - Varnish supply unit 6. PERIPHERAL DEVICES - Technotrans Water circulation system - Water cooled version - Grafix IR Dryer cabinet - IR Lamp - Centralised Electric Control Panel - Air supply cabinet - Pneumatic Compressor – centralized and is not available with machine - Plate punch and bending devices - Oil drip pan - Standard tools and accessories 7. GENERAL AND COMMERCIAL INFORMATION - Current Status - In Production - Machine Inspection - Possible - Available - Immediately - Available from - India - Cylinders - With some repaired marks - Price - On Request - Incoterms - LOT - General Conditions - Good

6

Golog Tibetan Autonomous Prefecture China

China

Manroland

102-2

1990

Sheet Fed / Offset

The Manroland 102-2 is a high-performance sheet-fed offset printing press designed for precision and efficiency in commercial printing applications. As part of the renowned 102 series, this two-color press delivers consistent print quality with perfecting capabilities, allowing for simultaneous printing on both sides of the sheet. Ideal for medium to large print runs, the 102-2 excels in producing high-quality brochures, catalogs, magazines, and packaging materials. Its robust construction, advanced automation features, and reliable performance make it a valuable asset for print shops seeking productivity and versatility.

2

Guang Zhou Shi China

China

Heidelberg

SX 52 4+LX

2014

Sheet Fed / Offset

The Heidelberg SX 52 4+LX is a high-performance sheet-fed offset press designed for precision printing in commercial and packaging applications. As part of the renowned Speedmaster series, this 4-color press with perfecting capabilities delivers exceptional print quality, efficiency, and versatility. Featuring advanced automation and Heidelberg's signature reliability, it is ideal for producing high-volume print jobs with consistent color accuracy and quick makeready times. Typical applications include brochures, catalogs, folding cartons, and other high-end printed materials requiring superior detail and finish.

4

Guang Zhou Shi China

China

Ryobi

924

2013

Sheet Fed / Offset

The Ryobi 924 is a high-performance sheet-fed offset printing press designed for commercial printing applications. As part of the Sheet Fed / Offset category, this 4-color machine offers precise color reproduction and efficient production capabilities. Known for its perfecting feature, the Ryobi 924 enables simultaneous printing on both sides of the sheet in a single pass, enhancing productivity and reducing turnaround times. Ideal for medium to large print runs, this press is well-suited for producing high-quality brochures, catalogs, magazines, and marketing materials with consistent color accuracy and sharp image reproduction.

4

Guang Zhou Shi China

China

Heidelberg

SM52-5H

2010

Sheet Fed / Offset

The Heidelberg SM52-5H is a high-performance sheet-fed offset printing press designed for precision and efficiency in commercial printing applications. As part of the renowned SM52 series, this 5-color press delivers exceptional print quality with perfecting capabilities, allowing for simultaneous printing on both sides of the sheet. Ideal for medium to high-volume production, it offers reliable performance, quick makeready times, and advanced automation features. Typical applications include brochures, catalogs, magazines, packaging, and promotional materials where consistent color reproduction and operational efficiency are critical.

5

Guang Zhou Shi China

China

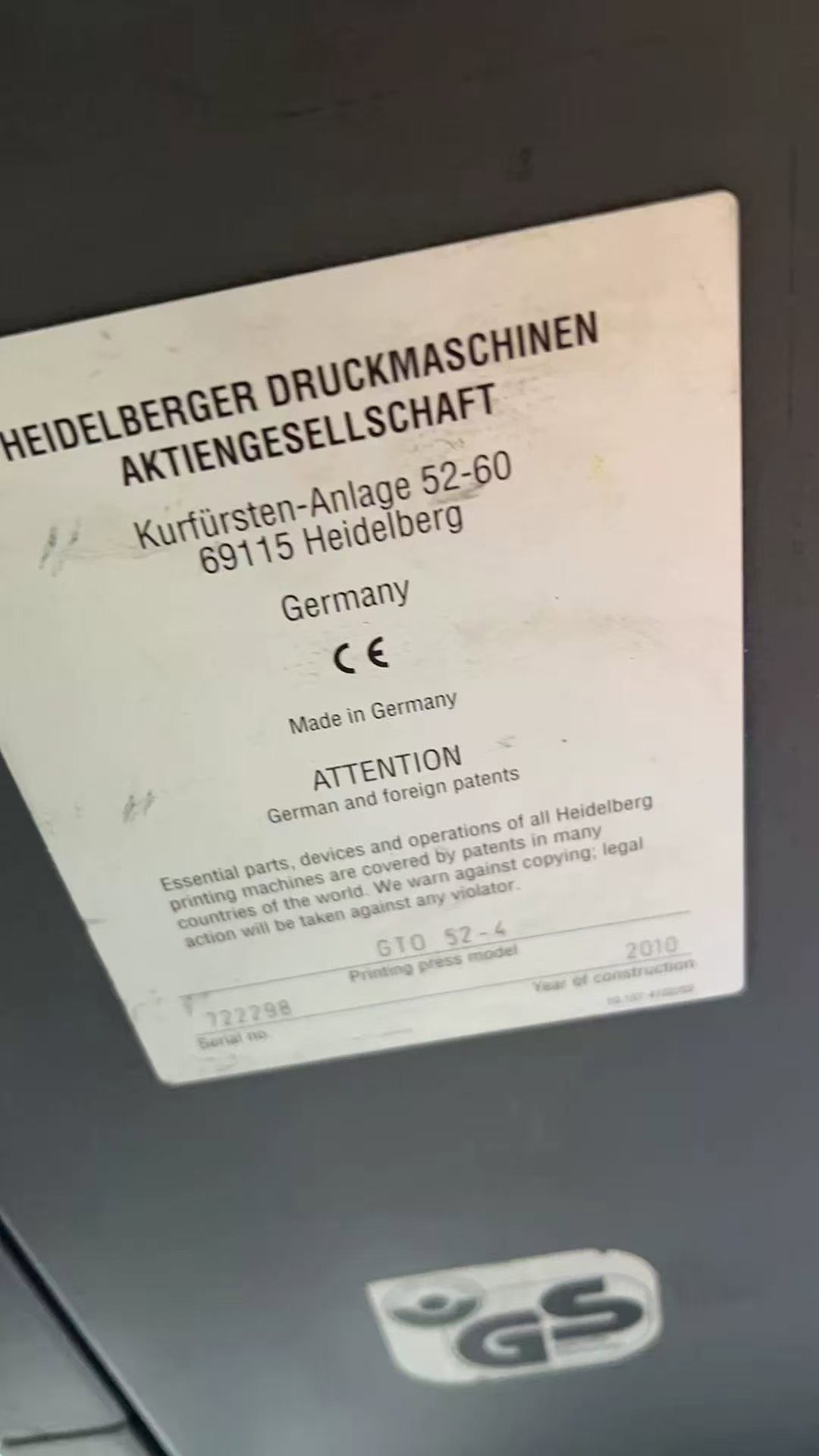

Heidelberg

GTO 52-5+

2010

Sheet Fed / Offset

The Heidelberg GTO 52-5+ is a high-performance sheet-fed offset press designed for precision printing in commercial and specialty applications. Belonging to the Sheet Fed / Offset category, this 5-color machine delivers exceptional print quality with perfecting capabilities, allowing simultaneous printing on both sides of the sheet. Known for its reliability and efficiency, the GTO 52-5+ is ideal for short to medium print runs, offering versatility for packaging, labels, and promotional materials. Its compact design and advanced automation features ensure consistent output while minimizing setup time and waste.

5

Guang Zhou Shi China

China

Heidelberg

XL106-8+LX

2015

Sheet Fed / Offset

The Heidelberg XL106-8+LX is a high-performance sheet-fed offset press designed for commercial printing applications requiring exceptional quality and productivity. As part of the Sheet Fed / Offset category, this 8-color press with perfecting capabilities delivers precise color reproduction, efficient paper handling, and reliable performance for medium to large print runs. Ideal for packaging, commercial printing, and specialty applications, the XL106-8+LX combines advanced automation with robust construction to meet demanding production requirements while maintaining operational efficiency.

8

Guang Zhou Shi China

China

KBA

142-5+L

1998

Sheet Fed / Offset

The KBA 142-5+L is a high-performance sheet-fed offset printing press designed for commercial and packaging applications. As part of the Sheet Fed / Offset category, this 5-color press delivers exceptional print quality, efficiency, and versatility. Featuring perfecting capabilities, it enables simultaneous printing on both sides of the sheet in a single pass, reducing production time and costs. Ideal for medium to large print runs, the 142-5+L excels in producing high-quality brochures, catalogs, packaging materials, and promotional items with precision and consistency.

5

Guang Zhou Shi China

China

KBA

142-6+L

1999

Sheet Fed / Offset

The KBA 142-6+L is a high-performance sheet-fed offset printing press designed for commercial and packaging applications. Part of the renowned KBA Rapida series, this 6-color press with perfecting capability delivers exceptional print quality, efficiency, and versatility. Featuring a maximum sheet size of 1020 x 1420 mm (40.16 x 55.91 inches), it is ideal for producing high-volume, high-quality printed materials such as brochures, catalogs, folding cartons, and labels. Built in 1999, the machine combines robust engineering with advanced automation, ensuring reliability and precision for demanding print environments.

6

Guang Zhou Shi China

China

Komori

LS 529

2007

Sheet Fed / Offset

The Komori LS 529 is a high-performance sheet-fed offset printing press designed for precision and efficiency in commercial printing environments. As part of the Sheet Fed / Offset category, this 5-color machine excels in producing vibrant, high-quality prints with exceptional consistency. Featuring perfecting capabilities, it allows for simultaneous printing on both sides of the sheet in a single pass, significantly enhancing productivity. Ideal for medium to large print runs, the LS 529 is well-suited for applications such as brochures, catalogs, magazines, and packaging materials, offering reliability and advanced automation for streamlined operations.

5

Guang Zhou Shi China

China

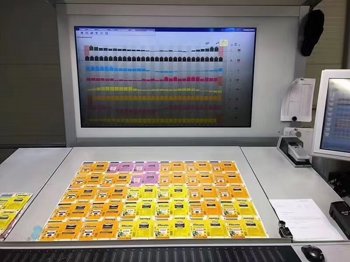

Heidelberg

GTO 52-4

2010

Sheet Fed / Offset

The Heidelberg GTO 52-4 is a high-performance sheet-fed offset press designed for precision printing in commercial and specialty applications. Belonging to the Sheet Fed / Offset category, this 4-color press delivers exceptional print quality with its perfecting capability, allowing simultaneous printing on both sides of the sheet in a single pass. Renowned for its reliability and efficiency, the GTO 52-4 is ideal for short to medium print runs, offering versatility for packaging, labels, brochures, and promotional materials. Its compact design, advanced automation, and Heidelberg's engineering excellence ensure consistent output with minimal waste, making it a preferred choice for printers seeking productivity and superior print results.

4

Guang Zhou Shi China

China

Komori

LS540

2010

Sheet Fed / Offset

The Komori LS540 is a high-performance sheet-fed offset printing press designed for commercial printing applications. Part of the renowned Komori lineup, this 5-color press combines precision engineering with advanced automation features to deliver exceptional print quality, efficiency, and versatility. With its perfecting capability, the LS540 enables simultaneous printing on both sides of the sheet in a single pass, making it ideal for producing high-volume commercial materials such as brochures, catalogs, magazines, and packaging. Known for its reliability and consistent output, the LS540 is well-suited for print shops seeking to optimize productivity while maintaining superior color accuracy and registration.

5

Guang Zhou Shi China

China

Heidelberg

XL75-4P+L

2009

Sheet Fed / Offset

The Heidelberg XL75-4P+L is a high-performance sheet-fed offset press designed for commercial printing applications requiring precision, efficiency, and versatility. As part of the renowned XL75 series, this 5-color press with perfecting capabilities delivers exceptional print quality, rapid production speeds, and advanced automation features. Ideal for medium to large print runs, it excels in producing high-end marketing materials, catalogs, brochures, and packaging prototypes with consistent color accuracy and registration. The XL75-4P+L combines Heidelberg's cutting-edge technology with robust engineering, ensuring reliability and reduced makeready times for enhanced productivity in demanding print environments.

5

Guang Zhou Shi China

China

KBA

Rapida RA 105-5 PWHA

2006

Sheet Fed / Offset

The KBA Rapida RA 105-5 PWHA is a high-performance sheet-fed offset press designed for precision printing in commercial and packaging applications. As part of the renowned Rapida series, this 5-color press delivers exceptional print quality, efficiency, and versatility. Featuring perfecting capabilities, it enables simultaneous printing on both sides of the sheet in a single pass, reducing production time and costs. Ideal for medium to large print runs, the RA 105-5 PWHA excels in producing high-quality brochures, catalogs, packaging materials, and promotional prints with consistent color accuracy and sharp detail.

5

Guang Zhou Shi China

China

Manroland

102-2

1993

Sheet Fed / Offset

The Manroland 102-2 is a high-performance sheet-fed offset printing press designed for precision and efficiency in commercial printing applications. As part of the renowned 102 series, this 2-color press combines robust engineering with advanced features to deliver consistent, high-quality prints. Ideal for medium to large print runs, the 102-2 excels in producing brochures, catalogs, magazines, and packaging materials. Its perfecting capability allows for simultaneous printing on both sides of the sheet, enhancing productivity and reducing turnaround times. Built in 1993, this press reflects Manroland's commitment to durability and reliability in offset printing technology.

2

Guang Zhou Shi China

China

Komori

Lithrone L-426

1994

Sheet Fed / Offset

The Komori Lithrone L-426 is a high-performance sheet-fed offset press designed for precision commercial printing applications. Belonging to the Sheet Fed / Offset category, this 4-color press offers reliable performance with perfecting capabilities, allowing for efficient double-sided printing in a single pass. Known for its robust construction and advanced automation features, the Lithrone L-426 delivers consistent print quality, high productivity, and operational efficiency. Ideal for medium to large print runs, this machine is well-suited for producing brochures, catalogs, magazines, and other high-quality printed materials.

4

Guang Zhou Shi China

China

Heidelberg

Speedmaster SM 102 V

1992

Sheet Fed / Offset

The Heidelberg Speedmaster SM 102 V is a high-performance sheet-fed offset press designed for precision printing in commercial and packaging applications. Renowned for its reliability and advanced technology, this two-color press offers perfecting capabilities, allowing simultaneous printing on both sides of the sheet in a single pass. With a maximum sheet size of 720 x 1020 mm (28.35 x 40.16 inches), it is ideal for producing high-quality brochures, catalogs, magazines, and packaging materials. Manufactured in 1992, the Speedmaster SM 102 V combines durability with efficiency, making it a valuable asset for print operations requiring consistent output and versatility.

2

Guang Zhou Shi China

China

Shinohara

794

2006

Sheet Fed / Offset

The Shinohara 794 is a high-performance sheet-fed offset printing press designed for precision and efficiency in commercial printing environments. As a 4-color perfecting press, it offers simultaneous printing on both sides of the sheet, making it ideal for medium to high-volume production. Known for its reliability and advanced features, this 2006 model delivers consistent print quality with a maximum sheet size of 600 x 790 mm (23.62 x 31.10 inches). The Shinohara 794 is well-suited for applications such as brochures, catalogs, magazines, and other high-quality printed materials where speed, accuracy, and versatility are essential.

4

Guang Zhou Shi China

China

Manroland

R 201

1989

Sheet Fed / Offset

The Manroland R 201 is a reliable sheet-fed offset printing press designed for high-quality commercial printing applications. As part of the Sheet Fed / Offset category, this single-color machine excels in producing precise and consistent prints with its perfecting capability, allowing for efficient double-sided printing in a single pass. Known for its durability and precision engineering, the R 201 is ideal for medium to large print runs, offering versatility for various substrates and applications such as brochures, catalogs, and packaging materials.

1

Guang Zhou Shi China

China

Heidelberg

SM52-5H

2003

Sheet Fed / Offset

The Heidelberg SM52-5H is a high-performance sheet-fed offset press designed for precision printing in commercial and packaging applications. As part of the renowned SM52 series, this 5-color press combines Heidelberg's engineering excellence with advanced automation, delivering consistent print quality, operational efficiency, and versatility. Featuring perfecting capabilities, it enables simultaneous printing on both sides of the sheet in a single pass, significantly enhancing productivity. Ideal for medium to high-volume production, the SM52-5H excels in producing brochures, catalogs, labels, and packaging materials with exceptional color accuracy and registration. Its robust construction, user-friendly controls, and reliable performance make it a preferred choice for printers seeking to optimize workflow and reduce downtime.

5

Guang Zhou Shi China

China

Heidelberg

CD102-5

2009

Sheet Fed / Offset

The Heidelberg CD102-5 is a high-performance sheet-fed offset press designed for commercial printing applications requiring superior quality and efficiency. Belonging to the Sheet Fed / Offset category, this 5-color press excels in producing vibrant, precise prints with its perfecting capability, allowing simultaneous printing on both sides of the sheet. Renowned for its reliability and advanced automation, the CD102-5 is ideal for medium to large print runs, including brochures, catalogs, packaging, and high-end marketing materials. Its robust construction and cutting-edge technology ensure consistent output, reduced waste, and enhanced productivity, making it a preferred choice for professional printers seeking exceptional color accuracy and operational flexibility.

5

Guang Zhou Shi China

China

Komori

Lithrone L-540

1991

Sheet Fed / Offset

The Komori Lithrone L-540 is a high-performance sheet-fed offset press designed for precision commercial printing applications. As part of the Sheet Fed / Offset category, this 5-color press offers exceptional print quality, reliability, and versatility. Key features include perfecting capability, allowing simultaneous printing on both sides of the sheet, and a robust construction engineered for long-term productivity. Ideal for medium to large print runs, the Lithrone L-540 excels in producing high-quality brochures, catalogs, magazines, and packaging materials with consistent color accuracy and sharp detail.

5

Guang Zhou Shi China

China

Ryobi

784 E

2010

Sheet Fed / Offset

The Ryobi 784 E is a high-performance sheet-fed offset printing press designed for precision and efficiency in commercial printing environments. As a 4-color perfecting press, it offers simultaneous printing on both sides of the sheet, making it ideal for medium to high-volume production of brochures, catalogs, magazines, and marketing materials. Known for its reliability and advanced automation features, this model delivers consistent print quality while optimizing workflow productivity. Built with Ryobi's engineering excellence, the 784 E combines robust construction with user-friendly operation, catering to the demands of modern print shops seeking versatility and cost-effective production.

4

Guang Zhou Shi China

China

Heidelberg

Speedmaster SM 102 F

1989

Sheet Fed / Offset

The Heidelberg Speedmaster SM 102 F is a high-performance sheet-fed offset press designed for precision commercial printing. Renowned for its reliability and advanced technology, this 5-color press excels in producing high-quality prints with exceptional color consistency and registration accuracy. Featuring perfecting capabilities, it efficiently handles both single- and double-sided printing in a single pass, making it ideal for medium to large print runs. Typical applications include brochures, catalogs, magazines, packaging, and promotional materials, where speed, versatility, and superior print quality are essential.

5

Guang Zhou Shi China

China

Komori

L 240P.1+1

2004

Sheet Fed / Offset

The Komori L 240P.1+1 is a high-performance sheet-fed offset press designed for precision printing in commercial and packaging applications. Belonging to the Sheet Fed / Offset category, this 2-color machine offers perfecting capabilities, allowing simultaneous printing on both sides of the sheet in a single pass. Known for its reliability and efficiency, the L 240P.1+1 delivers consistent print quality with sharp detail and vibrant colors. Its robust construction and advanced automation features make it ideal for medium to high-volume production, including brochures, catalogs, labels, and folding cartons.

2

Guang Zhou Shi China

China

Heidelberg

CD 102-4

2017

Sheet Fed / Offset

The Heidelberg CD 102-4 is a high-performance sheet-fed offset press designed for precision commercial printing applications. As part of the renowned Speedmaster series, this 4-color press delivers exceptional print quality, efficiency, and versatility. Featuring perfecting capabilities, it enables simultaneous printing on both sides of the sheet in a single pass, significantly enhancing productivity. Ideal for medium to large print runs, the CD 102-4 excels in producing high-quality brochures, catalogs, packaging, and promotional materials with consistent color accuracy and sharp detail.

4

Guang Zhou Shi China

China

Heidelberg

Speedmaster SM 52-2

2000

Sheet Fed / Offset

The Heidelberg Speedmaster SM 52-2 is a high-performance sheet-fed offset press designed for precision printing in commercial and specialty applications. As part of the renowned Speedmaster series, this 2-color press delivers exceptional print quality, efficiency, and versatility. Key features include perfecting capabilities, allowing simultaneous printing on both sides of the sheet, and compatibility with a wide range of substrates. Ideal for short to medium print runs, the SM 52-2 excels in producing high-quality brochures, catalogs, business forms, and packaging materials with consistent color accuracy and sharp detail.

2

Guang Zhou Shi China

China

Akiyama

Bestech BT P 440

2007

Sheet Fed / Offset

The Akiyama Bestech BT P 440 is a high-performance sheet-fed offset press designed for precision printing in commercial and packaging applications. As a 4-color perfecting press, it offers simultaneous printing on both sides of the sheet, enhancing productivity and efficiency. Known for its robust construction and advanced automation, this machine delivers consistent print quality, making it ideal for medium to large print runs, including brochures, catalogs, magazines, and packaging materials.

4

Guang Zhou Shi China

China

Heidelberg

CD102-5 L

2001

Sheet Fed / Offset

The Heidelberg CD102-5 L is a high-performance sheet-fed offset press designed for commercial printing applications, offering exceptional print quality and operational efficiency. As part of the renowned Speedmaster CD 102 series, this 5-color press delivers precise color reproduction, consistent registration, and versatile substrate handling. Equipped with perfecting capabilities, it enables simultaneous printing on both sides of the sheet in a single pass, significantly enhancing productivity. Ideal for medium to large print runs, the CD102-5 L is well-suited for producing high-end brochures, catalogs, magazines, packaging, and promotional materials with superior detail and color accuracy.

5

Guang Zhou Shi China

China

Komori

L440SP.4+4

2001

Sheet Fed / Offset

The Komori L440SP.4+4 is a high-performance sheet-fed offset press designed for precision printing in commercial and packaging applications. As part of the Sheet Fed / Offset category, this 4-color perfecting press delivers exceptional print quality, efficiency, and versatility. Key features include its ability to print on both sides of the sheet in a single pass, robust construction, and advanced automation for consistent results. Ideal for medium to large print runs, the L440SP.4+4 excels in producing high-quality brochures, catalogs, packaging materials, and promotional items with sharp detail and vibrant colors.

4

Guang Zhou Shi China

China

Manroland

661

1991

Sheet Fed / Offset

The Manroland 661 is a reliable sheet-fed offset printing press designed for high-quality commercial printing applications. Belonging to the Sheet Fed / Offset category, this single-color machine from 1991 offers perfecting capabilities, allowing for efficient printing on both sides of the sheet in a single pass. Known for its robust construction and precision engineering, the 661 is ideal for producing business forms, stationery, labels, and short to medium print runs with consistent results. Its compact design and user-friendly operation make it a practical choice for print shops seeking cost-effective production without compromising on quality.

1

Guang Zhou Shi China

China

Heidelberg

CD-102-F L

1991

Sheet Fed / Offset

The Heidelberg CD-102-F L is a high-performance sheet-fed offset press designed for precision commercial printing applications. As part of the renowned Speedmaster series, this 5-color press delivers exceptional print quality, efficiency, and versatility. Featuring perfecting capabilities, it enables simultaneous printing on both sides of the sheet in a single pass, making it ideal for producing high-volume brochures, catalogs, magazines, and packaging materials. Known for its robust construction and advanced automation, the CD-102-F L ensures consistent output, reduced makeready times, and enhanced productivity for commercial printers.

5

Guang Zhou Shi China

ChinaUV

Manroland

907+L

2003

Sheet Fed / Offset

The Manroland 907+L is a high-performance sheet-fed offset press designed for premium commercial printing applications. Part of the renowned 900 series, this 7-color press combines precision engineering with advanced automation to deliver exceptional print quality, productivity, and versatility. Featuring perfecting capabilities, it enables simultaneous printing on both sides of the sheet in a single pass, making it ideal for high-volume production of brochures, catalogs, magazines, packaging, and specialty print jobs. Built for reliability and efficiency, the 907+L offers robust paper handling, precise color control, and seamless integration into modern print workflows.

7

Guang Zhou Shi China

China

Heidelberg

SM102V

1993

Sheet Fed / Offset

The Heidelberg SM102V is a high-performance sheet-fed offset press designed for precision commercial printing applications. As part of the renowned Speedmaster series, this 4-color perfecting press delivers exceptional print quality, efficiency, and versatility. Ideal for medium to large print runs, the SM102V excels in producing high-quality brochures, catalogs, magazines, and packaging materials with consistent color accuracy and registration. Its perfecting capability allows simultaneous printing on both sides of the sheet in a single pass, significantly enhancing productivity while maintaining superior print standards.

4

Guang Zhou Shi China

China

Find the Right Equipment

Kindly add details of the equipment you seek; and you shall find. Our community of manufacturers, sellers, and professionals will procure it for you.

Click Here

The World of Print at your Fingertips

The Machine Dalal Mobile Apps

Download our Machine Dalal App Regular updates from our magazine with illustrations, innovations , commodities, history, media, art and a whole lot more from the magnificent world of Print.

Get the App

Login

Login