Popular Brands Or view all

Print, Packaging and Converting Machinery for Sale | Preowned & Preloved

PA250209A

Palamides

alpha 500 plus

2012

Stacker

max. size 51 x 33 cm age 2012 stacking delivery Palamides Alpha 500 double use automatic size recognition waste ejection jogging device pressing station roller table Delivery time: immediately from stock Ref: PA250209A Please ask for price. Worldwide delivery & installation

Stuttgart Germany

Germany

Ryobi

522

1996

Sheet Fed / Offset

We are pleased to offer: Used RYOBI 522 - Two-Colour Offset Press Year 1996 Specification The RYOBI 522 is a reliable two-colour sheetfed offset press designed for medium-run commercial printing. Manufactured in 1996, this model is well known for its solid Japanese engineering, consistent print quality and straightforward operation. Equipped with a continuous dampening system (Ryobimatic) and supported by a Technotrans refrigeration and recirculation unit, the press ensures stable ink-water balance and temperature control during production. It is ideal for commercial print shops producing brochures, stationery, flyers and general B3-format work. Sheetfed offset press 2 printing units (two colours) Maximum sheet size: 520 × 365 mm Minimum sheet size: 100 × 150 mm Maximum printing area: 505 × 350 mm Up to 13,000 sheets per hour (depending on stock and job) Paper thickness: 0.04 – 0.50 mm Suitable for light paper up to light board Dampening System: Continuous dampening (Ryobimatic type) Technotrans cooling and circulation unit Weight: Approx. 3,400 kg Good working order Available immediately

2

Hampshire United Kingdom

United Kingdom

Duplo

System 3500

2013

Booklet machines

We are pleased to offer: Used Duplo System 3500 Dynamic Booklet Maker Year 2013 Specification Counter: 246093 The Duplo System 3500 Dynamic Booklet Maker is an automated solution for producing booklets, brochures, and bound printed materials, ideal for digital printers and medium-volume production. It combines several finishing processes in a single line: Automated sheet feeding from digital printer output. Staple binding and folding of booklets. Front trimming for professional edge finishing. The system is composed of multiple integrated modules: DSF‑2200 Sheet Feeder – Feeds sheets or signatures from printers, collated or uncollated. DBM‑3500 Booklet Maker – Main machine that staples, folds, and assembles the booklets. DBM‑3500 Trimmer – Integrated front trimmer for uniform, professional finishing. This combination offers a semi-automatic to fully automatic workflow, streamlining the finishing process and reducing manual intervention. Production speed: Up to 3,000 booklets per hour (typical for A5 size). Feeding capacity (DSF‑2200): Upper tray: ~65 mm Lower tray: ~200 mm Feeding speed: up to ~200 sheets per minute Paper Sizes and Weights Paper size range: approximately 105 × 148 mm up to 320 × 460 mm depending on configuration. Paper Capacity: 20 sheets [Cover x 1(300gsm) 19 sheets (81.4 gsm) equivalent Stitch heads: 2 Compatible paper weight: approximately 52 – 300 gsm. Maximum sheets per booklet: about 20 sheets plus cover in standard configuration. Dimensions and Power: Overall dimensions (with DSF‑2200 and trimmer): ~4.48 m long × 0.75 m wide × 1.03 m high Combined weight: ~395 kg Power supply: 230 V, 50 Hz Good working order Available immediately

Hampshire United Kingdom

United Kingdom

Rilecart

B 596

1993

Binding machine for wire-o

We are pleased to offer: Rilecart B- 596 Automatic Double Wirobinding Machine Year 1993 Specification The Rilecart B‑596 is a fully automatic double-loop wire binding machine, specifically designed for the efficient production of calendars, catalogues, and similar bound products. Manufactured in 1993, this robust and reliable unit is capable of handling both short and long runs with consistent precision and speed. It features a belt delivery system and is supplied with 2.1 mm and 3.1 mm punching tools. The B‑596 supports various wire pitches (2:1", 3:1", and 4:1") and includes a hanger binding station with an automatic feeder for enhanced productivity. The centralised automatic lubrication system ensures smooth operation and reduced maintenance. This machine remains in very good working condition and is well-suited to industrial bookbinding environments seeking a dependable wirebinding solution. Max. binding size: 500 × 350 mm Min. binding size: 60 × 80 mm Binding thickness: 1.5 mm to 17.5 mm Pitch options: 2:1″, 3:1″, 4:1″ Speed: 500 to 2,300 cycles/hour Good working order Available immediately

Hampshire United Kingdom

United Kingdom

Franklin

HS 190

2000

Hot Foil Stamping

We are pleased to offer: Used Franklin HS 190 Foil and Hologram Machine with Pneumatic Pull Year 2000 Specification The Franklin HS190 Foil and Hologram Machine with Pneumatic Pull for Paper, Board and Plastic is a used finishing machine designed to: Apply foil or holographic film onto paper, board or plastic using pressure and, where applicable, heat. Feed material using a pneumatic pull system, which ensures a steady and accurate advance of the substrate — this system uses compressed air to control material tension and feed. It is typically used in the finishing of labels, packaging, cards or promotional materials to create metallic or holographic effects. Stamping Area: Typically, up to 150 x 225 mm (subject to chase size) Air Pressure Requirement: 80 - 100 PSI Impression Force: Up to 2 - 3 tonnes (depending on the pneumatic cylinder) Feed system: Pneumatic “pull” feed of continuous material. Tension control: Pneumatic tension regulation for both the foil and the substrate. Foil reel diameter: Commonly up to ~250 mm. Temperature Control: Digital, adjustable up to 250°C Compatible materials: Paper, board, flexible PVC and other plastics. Control panel: Push-button and analogue dial controls for key adjustments (pressure, speed). Operation Mode: Foot pedal or manual (often fitted with two-hand safety starts) Electrical supply: Typically, 220 V, 50 Hz Good working order Available immediately

Hampshire United Kingdom

United Kingdom

Miller Johannisberg

Cylinder – Converted

1970

Hot Foil Stamping

We are pleased to offer: Used Miller Johannisberg Cylinder – Converted for Hot Foil Stamping Year 1970 Specification We are pleased to offer this 1970 Miller Johannisberg Cylinder 730 × 1040 mm, professionally converted for hot foil stamping. Originally manufactured as a high-quality cylinder press, this machine has been adapted to perform hot foil stamping applications, making it a robust and cost-effective solution for companies involved in print finishing, packaging, and speciality printing. The cylinder construction ensures consistent pressure distribution and excellent registration accuracy, ideal for large-format foil stamping on a wide range of materials. Its heavy-duty German engineering provides long-term durability and stable performance in demanding production environments. Type: Cylinder Press – Converted for Hot Foil Stamping Maximum Sheet Size: 730 x 1040 mm (some listings state 720 x 1040 mm) Minimum Sheet Size: 297 x 420 mm Maximum Stamping Area: 710 x 1020 mm Substrate Thickness: 54 – 400 g/m² (approx. 0.1 – 0.5 mm) Speed: Up to 3,000–3,500 impressions per hour (mechanical speed), with effective operating speeds depending on complexity Heated Bed: Usually 4 to 6 independent heat zones, temperature range 0–200°C Die Height: Set for 6.35 mm (standard), but often convertible to 7 mm Foil Feeding: Multiple independent foil pull rollers (usually 2 or 3) with precision stepper drives Max Foil Roll Diameter: 125 mm Maximum Foil Width: 1020 mm General Dimensions: Approx. 1,850mm(H) x 1,240mm(W) x 3,800mm(L) Weight: Approximately 8,500 kg Power/Air: 3 Phase, 380/415V, 50/60 Hz, 32-36 Amps per phase; 5 bar (75psi) air supply Good working order Available immediately

Hampshire United Kingdom

United Kingdom

Gietz

FSA - 720 Foiling Platen

1986

Hot Foil Stamping

We are pleased to offer: Used Gietz MF Jacket Foiling Machine Year 1981 Specification Enhance your finishing quality with this Gietz MF Jacket Foiling Machine from 1981, ideal for print shops, luxury packaging, and premium finishing applications. Designed for high-precision foil stamping, this machine is perfect for producing books, folders, covers, and cards with professional, metallic finishes. Key Features: Classic, robust and reliable foiling machine Perfect for high-end print and customisation jobs Semi-automatic operation, efficient and easy to adjust Compatible with a variety of paper types, card stocks and laminates Built for durability and precision in every stamped piece Model: Gietz MF Jacket Type: Foiling / Hot Stamping Machine Operation: Semi-automatic Maximum work size: Approx. 400 × 600 mm (depends on material) Minimum work size: Approx. 150 × 200 mm Maximum material thickness: 0.8–1.2 mm (depending on paper/card type) Production speed:~1,500–2,000 sheets/hour (depending on application) Stamping type: Metallic foil, special foils Compatible materials: Paper, card stock, fine laminates Heating system: Electric, adjustable temperature Sheet feeding: Manual or semi-automatic (model dependent) Approximate dimensions: 2,000 × 1,200 × 1,500 mm Approximate weight: 900–1,100 kg Good working order Available immediately

Hampshire United Kingdom

United Kingdom

KBA

RA 76-8-P

2022

Sheet Fed / Offset

Eight Color with Perfectin Format max.: 530 X 750 mm Format min.: 210 X 297 mm Image area: 520 X 740 mm Stock thickness: 0,04 - 0,6 mm Pile Height Feeder: 1200 mm Pile Height Delivery: 1360 mm Speed max.: 16.000 s/h Impression Count: 57 MIO. Specification: Drive Tronic Feeder ColorTronic - Press control ErgoTronic control console QualiControl Densitometer Wallscreen ErgoTronic Color Drive ErgoTronic ACR (Automatic Camera Register) FAPC Full automatic Plate Changer ErgoTronic automatic make ready CleanTronic - Syncron all automatic washing devices Vari Damp alcohol dampening TECHNOTRANS Combi Refrigeration Unit Ink Unit Temperature control Air Tronic Delivery Powder Spray Performance Package SIS

8

Oslo Norway

Norway

Heidelberg

S-Cylinder with Gold Foil and 2 Pull System

Hot Foil Stamping

We are pleased to offer: Used Original Heidelberg S-Cylinder (540 × 720 mm) with Gold Foil & 2 Pull Systems Specification The Heidelberg S-Cylinder (540 × 720 mm) is a heavy-duty, high-precision cylinder press originally designed for letterpress printing and widely used today for hot foil stamping, embossing, debossing and die-cutting applications. Renowned for its robust engineering and long service life, the S-Cylinder is a reliable solution for commercial print finishing and specialist packaging production. In this configuration, the machine is equipped with a gold foil cylinder and two foil pull systems, enabling efficient and precise hot foil stamping. The dual pull system allows accurate foil advance control, improving material efficiency and ensuring consistent, high-quality finishing across medium and large formats. The 540 × 720 mm format offers excellent versatility for a wide range of substrates, including paper and board.Cutting and creasing cylinder. Maximum sheet size: 540 x 720 mm / 21 1/4 X 28 3/8 in Minimum sheet size: Approximately 115 × 160 mm (depending on configuration) Maximum mechanical speed: Up to approx. 3,500 sheets per hour (in standard operation) Gripper margin: Approx. 8–10 mm Machine weight: Approx. 4,500–5,000 kg (depending on equipment fitted) Gold foil stamping cylinder fitted Two foil pull systems for controlled foil advance Good working order Test possible Available immediately https://youtu.be/kYhsNsUzFXo

Hampshire United Kingdom

United Kingdom

Horizon

Collator VAC-1000m

2016

Collating and inserting lines

We are pleased to offer: Used Horizon 1000m Tower Collating Module Year 2016 Specification The Horizon 1000M Tower is a modular collating (gathering) tower designed to expand the capacity of a Horizon VAC-1000 collating system. It is intended as an expansion module that integrates seamlessly with other Horizon towers to build a multi-tower collating line for high-volume sheet gathering prior to finishing. Unlike the primary VAC-1000a tower, the 1000M tower does not include its own control display and is configured solely to add additional feed stations to an existing system. Its design allows print finishing operations to adapt the system to varying production volumes by increasing the total number of sheet bins available. Horizon’s rotary vacuum suction feeding system ensures reliable paper feeding and stacking across a wide range of paper weights and formats, supporting continuous production flow when combined with other towers in a VAC-1000 line. VAC-1000 Model: VAC-1000m Serial Number: 024301 Number of Bins: 10 bins each bin Sheet Feeding System: Suction Rotor System Sheet Size (Width × Length): Max. 350 × 500 mm / Min. 148* × 148 mm *Machine can collate the sheet of 120 mm or 4.73” width when option guide is attached. Sheet Weight Range: Art / Coated Paper: 73.3 to 207 gsm, Normal Paper: 52.3 to 207 gsm, 8-page fold signature: up to 104.7 gsm Bin Stack Height: Max. Stack Height: 55 mm / Max. Stack Weight: 11 kg or 24.3 lb each bin Sheet Overlap Front delivery: 4 Steps Maximum, Large, Middle and Small / Rear delivery: 4 Steps Maximum, Large, Middle and Small Production Speed 10 bins: Max. 9,900 sets per hour (A5LEF, Straight Receiving) Max. 8,900 sets per hour (A4LEF, Straight Receiving) *Production speed is limited by the type of finisher or sheet weight. Receiving Tray: Swing Type SW-20 /Stack Type ST-60, ST-40 / Jogger Type PJ-77, PJ-77R Voltage / Frequency: Single Phase 208 / 220 V, 50 or 60 Hz, Single Phase 230 to 240 V, 50 or 60 Hz Machine Dimensions: 930 (W) × 652 (D)* × 1,962 (H) mm *1 Blower box excluded: 693 mm or 27.3” (D) when including the projection Good working order Available immediately

Hampshire United Kingdom

United Kingdom

Sitma

C-80-750

1998

Wrapping machines

We are pleased to offer: Used Sitma C-80-750 (8‑Station Polywrapping Line) Year 1998 Specification The Sitma C-80/750 8‑station polywrapping line is a robust, high‑capacity automated packaging system designed for polywrapping a wide range of printed products, books, magazines, catalogues, brochures and related materials. Built for continuous production, this system integrates multiple stations in a linear configuration, enabling efficient product feeding, wrapping, and sealing in a single automated flow. The inclusion of 8 stations allows for staged processing — typically loading, folding, sealing and ejection — while the shuttle feeder provides stable and controlled feeding of products into the line. The machine is completed with a polywrapping module that wraps products in clear or specialty poly film, delivering clean, wrinkle‑free packaging ideal for resale, distribution and automated handling. Despite its age, the Sitma C80/750 remains valued for its mechanical reliability, straightforward operation and modular design, making it suitable for print finishing houses, mail order fulfilment centres, bookbinders and packaging facilities looking to maintain production with a dependable polywrapping line. Stations: 8 processing stations Feeder: Single shuttle feeder for consistent product transport Wrapping System: Polywrapping with film folding and sealing Typical production speed: approximately 2,000 – 6,000 units per hour, depending on product size, conveyor settings and operator configuration Feeder control: shuttle feeder with adjustable speed and timing Film type: polyethylene or BOPP film, depending on product requirement Minimum product size: 150 x 500 mm Maximum product size: 100 x 350 mm Max. Pile Height: 1/200 mm Typical Products Handled: Printed books, catalogues and brochures, magazines and periodicals, media products (CD/DVD cases, booklets), promotional packs and multi‑page sets requiring polywrapping. Good working order Available immediately

Hampshire United Kingdom

United Kingdom1983

Bobst

SP 102 E

1983

Die cutting

autoplatine, die cutting machine. Year 1983 max 102x720 min. 40x35 speed 7.500 s/h pressure 250 t. Stripping device

Provincia di Siena Italy

Italy

Zhejiang Feiyun

FG-800C4/6

2019

Folder Gluer Machines

folding gluing machine year 2019 Size 800 mm Straight line Crash lock bottom 4/6 corners device Gluing device Delivery belt

Provincia di Siena Italy

Italy

Omet

Flexy S 330

2008

Flexographic equipment

Label Flexo printing machine Year 2008 Max Web Width: 330mm Thickness: from 50 to 350 micron Servo driver Configuration: Unwinder 3 x Corona Treatment 8 x Flexo Printing Units 8 x GEW UV dryers Delam/Relam Cold foil Cooled drums (with chiller) 2 x die cutting units Web video register control Silicone cut. Blade cutting Double Rewinder Accessories: 8 x cylinders Z96,Z144,Z74,Z82 1x magnetic cylinders Z96,Z144 8 x anilox

Provincia di Siena Italy

Italy

CODIMAG

Viva 340

2009

Label Printing

Printing width: 330 mm Web width max.: 340 mm Web width min.: 120 mm Printing length max.: 305 mm Printing length min.: 50 mm Speed max.: 12.000 Specification: 1 Unwind Unit - 1000 mm diameter 4 water less Offset printing units PC with Touch Screen AEIC Ink Unit remote control cylinder circumference 14" automatic washing devices-including squeegee system Web break monitoring Ink Unit temperature control 4 AP Ink agitators 4 IST UV Dryer - Type MBS 5 80 Watt for one dryer (Printing Units) 1 IST UV Dryer - Type MBS 5 120 Watt (Coating Unit) 1 Flexo-Printing Unit for coating with base and register trolley incl. Coating supply 1 Softal Corona unit 1 BST Promark Video Web monitoring 1 Format variable punching unit Magnetic cylinder punching plate - thickness 0,44 mm Gap Master variable punching depth adjustment Electropneumatic on and off and KMS 1 KELVA CWC Web cleaning system 1 ELTEX Anti Static device with 5 Ent ionizing bars 1 Label grid rewinder - 799 mm diameter 1 Rewinder Unit - 700 mm diameter 1 Longitudinal cutting device with 4 knifes 1 Electrical equipment and control panel Condition: Very good (still in Production) Available: Immediately

Oslo Norway

Norway

HP

Indigo 7900

2018

Digital Press

Mach. Nr.: IL47100250 Counter: 12,5 Mil. Equipment: Complete with 7 colours, including white-ink option and OFIR (On place Fast Ink Replacement) Including Auto Alert Agent Print options: One-shot Sandwich-printing Raised printing Textured effects (digital embossing / digital pregen) Fluid-ink 4 trays, one tray equipped with thick substrate kit (thickness up to 480 micron) 1 stacker Including HP Smart Stream production Pro Print Server OS hard drive with 230 GB Hot-folder / jobs hard disk with 1.36 TB Total of SAS-hard drives of 4.68 TB (16x 300GB SAS-hard drives) Servertype: HP ProLiant DL380p Gen8 Condition: like New Available: Immediately

Oslo Norway

NorwayMCID_165

Heidelberg

Speedmaster SM CD 102-6 LX

2000

Sheet Fed / Offset

HEIDELBERG CD102-6L - 6 Printing Units + 1 Coating Unit - Year – 2000 - Impressions 210 million (Now counter is showing 0) - Straight Printing Press TECHNICAL SPECIFICATION - Speed 15.000 sheet/h - Max paper size 720 x 1020 mm (28” x40”) - Printable Stock Thickness – 0.03mm – 0.8mm PRESS CONFIGURATION / FEATURES INCLUDED 1. PRESS CONTROL - CP 2000 centre with touch screen - Remote ink control with main and fine ink display - Remote register control (Diagonal, Lateral and Circumferential) - Remote Pressure control - CIP3 Connectivity Support - Job saving and memory Management - Service Diagnosis - Day light illuminator and cassette or memory card for job memories - Sample sheer holder 2. FEEDER UNIT - Preset Feeder - Stream feeder - Non-Stop feeder with ramps - Display for monitoring sheet travel - Automatic Format setting - Stream feeder with belt - Electronic double sheet detection - Electro mechanic double sheet detection - Electronic side lay control, - Anti-static on feeder - Automatic sheet arrival control - Automatic Front lay control - With sheet deposit on the feeder - Rear edge blowers 3. PRINTING UNIT - Auto Plate with 0.15mm under cut - 3 IST UV lamps + 3 End of press - Trible Diameter transfer cylinders - Double Diameter impression cylinders - Chrome Cylinders - Steel Grippers - Air control between cylinders to ensure smooth sheet travel - Blanket cylinder for mounting blanket with metal edged - Plate cylinder circumferential adjustment - Auto blanket wash with programmable system - Remote Oscillation roller timing adjustment for gripper to tail colour variation - Alcolor dampening system with Vario system - Technotrans with Combination device – Alcohol Free 4. DELIVERY UNIT - Preset Delivery - Extended delivery – X3 - High Pile Delivery - Preset Delivery control - Preset Format setting - Powder spray system - Sheet de-curler - Air blower control - Delivery fans to ensure proper filing - Sheet guidance with cooled guide plate - Sheet slow down device with 10mm suction drum - Narrow supporting roller between the suction rollers 5. COATING UNIT - Two roller coating system with chambered blade - Varnish supply unit 6. PERIPHERAL DEVICES - Technotrans Water circulation system - Water cooled version - Grafix IR Dryer cabinet - IR Lamp - Centralised Electric Control Panel - Air supply cabinet - Pneumatic Compressor – centralized and is not available with machine - Plate punch and bending devices - Oil drip pan - Standard tools and accessories 7. GENERAL AND COMMERCIAL INFORMATION - Current Status - In Production - Machine Inspection - Possible - Available - Immediately - Available from - India - Cylinders - With some repaired marks - Price - On Request - Incoterms - LOT - General Conditions - Good

6

Golog Tibetan Autonomous Prefecture China

China

Yawa

1050

2013

Die cutting

We are pleased to offer: Yawa 1050 TYM / TDS 750 × 1050 Automatic Die Cutter with Foiling Year 2016 Specification The 2016 Yawa 1050 TYM / TDS 1050 is a heavy-duty automatic flatbed die-cutting and hot foil stamping machine, designed for high-volume commercial print finishing and packaging production. This model combines powerful die-cutting performance with integrated hot foil stamping in a single pass, making it ideal for manufacturers requiring precision cutting together with premium decorative finishes. Equipped with a 300-tonne pressure capacity, three foil pull systems, and 12 independently controlled heating zones, the machine delivers consistent foil transfer and accurate die cutting across medium and large formats. The inclusion of non-stop feeder and non-stop delivery systems ensures continuous production, reducing downtime during pallet changes and increasing overall productivity. This configuration is particularly suitable for folding carton production, luxury packaging, and high-end printed materials. Maximum sheet size: 750 × 1050 mm Minimum sheet size: approx. 360 × 400 mm (depending on application) Maximum die-cutting area: approx. 1040 × 730 mm Suitable for paper, solid board and corrugated board (up to approx. 4 mm thickness, depending on material) Maximum mechanical speed: up to approx. 7,500 sheets per hour Foil stamping speed: up to approx. 6,500 sheets per hour (depending on job complexity) Maximum cutting pressure: 300 tonnes Three longitudinal foil pull systems Programmable foil advance control 12 heating zones for precise temperature distribution Compatible with metallic, pigment and holographic foils Non-stop feeder for continuous sheet loading Non-stop delivery for uninterrupted stacking High-capacity pile loading and delivery systems Precision gripper bar transport for stable sheet control ????Heavy-duty steel frame construction Flatbed die-cutting system with closed chase PLC control with touchscreen interface Automatic lubrication system (where fitted) Safety guarding compliant with industrial standards ????Typical Applications: Folding carton die cutting Luxury packaging with hot foil stamping Premium printed materials (invitations, covers, presentation folders) Decorative metallic and holographic foil finishing Combined die cutting and foil stamping production in a single pass Good working order Available immediately

Hampshire United Kingdom

United Kingdom

Duplo

System 3500

2013

Booklet machines

We are pleased to offer: Used Duplo System 3500 Dynamic Booklet Maker Year 2013 Specification The Duplo System 3500 Dynamic Booklet Maker is an automated solution for producing booklets, brochures, and bound printed materials, ideal for digital printers and medium-volume production. It combines several finishing processes in a single line: Automated sheet feeding from digital printer output. Staple binding and folding of booklets. Front trimming for professional edge finishing. The system is composed of multiple integrated modules: DSF‑2200 Sheet Feeder – Feeds sheets or signatures from printers, collated or uncollated. DBM‑3500 Booklet Maker – Main machine that staples, folds, and assembles the booklets. DBM‑3500 Trimmer – Integrated front trimmer for uniform, professional finishing. This combination offers a semi-automatic to fully automatic workflow, streamlining the finishing process and reducing manual intervention. Production speed: Up to 3,000 booklets per hour (typical for A5 size). Feeding capacity (DSF‑2200): Upper tray: ~65 mm Lower tray: ~200 mm Feeding speed: up to ~200 sheets per minute Paper Sizes and Weights Paper size range: approximately 105 × 148 mm up to 320 × 460 mm depending on configuration. Paper Capacity: 20 sheets [Cover x 1(300gsm) 19 sheets (81.4 gsm) equivalent Stitch heads: 2 Compatible paper weight: approximately 52 – 300 gsm. Maximum sheets per booklet: about 20 sheets plus cover in standard configuration. Dimensions and Power: Overall dimensions (with DSF‑2200 and trimmer): ~4.48 m long × 0.75 m wide × 1.03 m high Combined weight: ~395 kg Power supply: 230 V, 50 Hz Good working order Available immediately

Hampshire United Kingdom

United Kingdom

Viking

VK 1330 Hand-Fed Platen Die-Cutter

1998

Die cutting

We are pleased to offer: Used Viking VK1330 Hand-Fed Platen Year 1998 Specification The Viking VK1130 is a hand-fed platen press / die-cutter built for heavy-duty finishing work in print, packaging and boxmaking environments. This robust industrial machine is designed to press, cut or die-cut sheet materials using a heavy platen mechanism operated manually or in semi-automatic modes. It is valued for precision, durability and flexibility when processing thicker substrates that require firm, controlled press pressure. The VK1130 is typically equipped with a solid frame and platen design that ensures stable operation and accurate cutting or pressing even on complex or heavy materials. The hand-fed operation makes it suitable for both short runs and moderate production volumes, where ease of setup and reliability are priorities. Max Sheet Size (Length × Width):1330 × 960 mm Operating Modes: Single, continuous, dwell Max Speed: up to 1,500 sheets/hour Power Supply: 3-phase, ~380 V (typical for UK/Europe) Safety Features: Goal-post guards, safety edges, fail-safe brakes Weight: approx. 6,200 kg Good working order Available immediately

Hampshire United Kingdom

United KingdomPO260008A

Polar

115 ED

2000

Guillotines

width 137 cm age 2000 AUTOTRIM computer control with monitor colour screen air table metallized 2 side tables jogger RA-4 with press roller Transomat TR 130 EL-4 handling from right to the left Ref: PO260008A Please ask for price. Worldwide delivery & installation

Stuttgart Germany

Germany

Manroland

102-2

1990

Sheet Fed / Offset

The Manroland 102-2 is a high-performance sheet-fed offset printing press designed for precision and efficiency in commercial printing applications. As part of the renowned 102 series, this two-color press delivers consistent print quality with perfecting capabilities, allowing for simultaneous printing on both sides of the sheet. Ideal for medium to large print runs, the 102-2 excels in producing high-quality brochures, catalogs, magazines, and packaging materials. Its robust construction, advanced automation features, and reliable performance make it a valuable asset for print shops seeking productivity and versatility.

2

Guang Zhou Shi China

China

Muller Martini

TIGRA

2004

Perfect binder lines

2004 Used Muller Martini model Tigra perfect binder. 9 Clamps perfect binder with Milling & Notching unit, Two bag waste collector, Spine EVA glue unit with a Premelter & Side glue unit, Pile Cover feeder, Pressing station, Lay down. 16x Gathering unit with Criss cross delivery unit for rejection and Gathering & Hand feed unit. Conveyors to 3 knife Esprit trimmer. Machine worked one shift and was bought new by the customer. 460V, 3 Ph, 50/60Hz.

Regional Municipality of Niagara Canada

Canada

DAI`S

1370

2016

Paper/Sheet Cutting Machines

The DAI'S Model 1370 is a precision paper and sheet cutting machine designed for industrial applications, offering reliable performance for cutting various paper materials with accuracy. Ideal for print shops, packaging manufacturers, and paper processing facilities, this machine ensures clean, consistent cuts while enhancing productivity. Manufactured in 2016, the Model 1370 combines durability with efficient operation, making it a practical choice for high-volume cutting tasks.

Guang Zhou Shi China

China

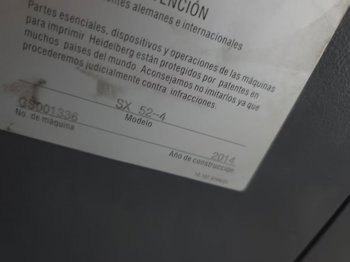

Heidelberg

SX 52 4+LX

2014

Sheet Fed / Offset

The Heidelberg SX 52 4+LX is a high-performance sheet-fed offset press designed for precision printing in commercial and packaging applications. As part of the renowned Speedmaster series, this 4-color press with perfecting capabilities delivers exceptional print quality, efficiency, and versatility. Featuring advanced automation and Heidelberg's signature reliability, it is ideal for producing high-volume print jobs with consistent color accuracy and quick makeready times. Typical applications include brochures, catalogs, folding cartons, and other high-end printed materials requiring superior detail and finish.

4

Guang Zhou Shi China

China

Ryobi

924

2013

Sheet Fed / Offset

The Ryobi 924 is a high-performance sheet-fed offset printing press designed for commercial printing applications. As part of the Sheet Fed / Offset category, this 4-color machine offers precise color reproduction and efficient production capabilities. Known for its perfecting feature, the Ryobi 924 enables simultaneous printing on both sides of the sheet in a single pass, enhancing productivity and reducing turnaround times. Ideal for medium to large print runs, this press is well-suited for producing high-quality brochures, catalogs, magazines, and marketing materials with consistent color accuracy and sharp image reproduction.

4

Guang Zhou Shi China

China

Heidelberg

SM52-5H

2010

Sheet Fed / Offset

The Heidelberg SM52-5H is a high-performance sheet-fed offset printing press designed for precision and efficiency in commercial printing applications. As part of the renowned SM52 series, this 5-color press delivers exceptional print quality with perfecting capabilities, allowing for simultaneous printing on both sides of the sheet. Ideal for medium to high-volume production, it offers reliable performance, quick makeready times, and advanced automation features. Typical applications include brochures, catalogs, magazines, packaging, and promotional materials where consistent color reproduction and operational efficiency are critical.

5

Guang Zhou Shi China

China

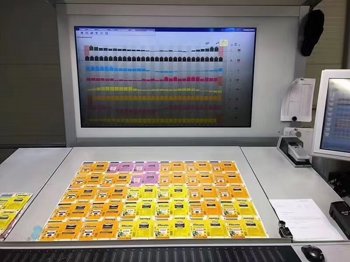

Heidelberg

GTO 52-5+

2010

Sheet Fed / Offset

The Heidelberg GTO 52-5+ is a high-performance sheet-fed offset press designed for precision printing in commercial and specialty applications. Belonging to the Sheet Fed / Offset category, this 5-color machine delivers exceptional print quality with perfecting capabilities, allowing simultaneous printing on both sides of the sheet. Known for its reliability and efficiency, the GTO 52-5+ is ideal for short to medium print runs, offering versatility for packaging, labels, and promotional materials. Its compact design and advanced automation features ensure consistent output while minimizing setup time and waste.

5

Guang Zhou Shi China

China

Heidelberg

XL106-8+LX

2015

Sheet Fed / Offset

The Heidelberg XL106-8+LX is a high-performance sheet-fed offset press designed for commercial printing applications requiring exceptional quality and productivity. As part of the Sheet Fed / Offset category, this 8-color press with perfecting capabilities delivers precise color reproduction, efficient paper handling, and reliable performance for medium to large print runs. Ideal for packaging, commercial printing, and specialty applications, the XL106-8+LX combines advanced automation with robust construction to meet demanding production requirements while maintaining operational efficiency.

8

Guang Zhou Shi China

China

KBA

142-5+L

1998

Sheet Fed / Offset

The KBA 142-5+L is a high-performance sheet-fed offset printing press designed for commercial and packaging applications. As part of the Sheet Fed / Offset category, this 5-color press delivers exceptional print quality, efficiency, and versatility. Featuring perfecting capabilities, it enables simultaneous printing on both sides of the sheet in a single pass, reducing production time and costs. Ideal for medium to large print runs, the 142-5+L excels in producing high-quality brochures, catalogs, packaging materials, and promotional items with precision and consistency.

5

Guang Zhou Shi China

China

KONGQUE

1500

2013

Die cutting

The KONGQUE 1500 is a specialized die cutting machine designed for precision paper converting applications. Operating in the die cutting category, this 2013 model delivers accurate cutting, creasing, and embossing for various paper materials. Known for its reliability and efficiency, the machine is ideal for producing packaging, labels, and decorative paper products. Its robust construction ensures consistent performance in high-volume production environments, making it a valuable asset for printing and packaging industries.

Guang Zhou Shi China

China

KBA

142-6+L

1999

Sheet Fed / Offset

The KBA 142-6+L is a high-performance sheet-fed offset printing press designed for commercial and packaging applications. Part of the renowned KBA Rapida series, this 6-color press with perfecting capability delivers exceptional print quality, efficiency, and versatility. Featuring a maximum sheet size of 1020 x 1420 mm (40.16 x 55.91 inches), it is ideal for producing high-volume, high-quality printed materials such as brochures, catalogs, folding cartons, and labels. Built in 1999, the machine combines robust engineering with advanced automation, ensuring reliability and precision for demanding print environments.

6

Guang Zhou Shi China

China

Komori

LS 529

2007

Sheet Fed / Offset

The Komori LS 529 is a high-performance sheet-fed offset printing press designed for precision and efficiency in commercial printing environments. As part of the Sheet Fed / Offset category, this 5-color machine excels in producing vibrant, high-quality prints with exceptional consistency. Featuring perfecting capabilities, it allows for simultaneous printing on both sides of the sheet in a single pass, significantly enhancing productivity. Ideal for medium to large print runs, the LS 529 is well-suited for applications such as brochures, catalogs, magazines, and packaging materials, offering reliability and advanced automation for streamlined operations.

5

Guang Zhou Shi China

China

HONGSEN

920

2020

Laminating machines

The HONGSEN 920 is a high-performance laminating machine designed for industrial and commercial applications. As part of the Laminating machines category, this model excels in providing durable, protective laminations for documents, photographs, and various printed materials. Known for its reliability and efficiency, the HONGSEN 920 ensures smooth operation with minimal maintenance, making it ideal for print shops, offices, and production environments. Its robust construction and precise engineering deliver consistent results, enhancing the longevity and appearance of laminated items.

Guang Zhou Shi China

China

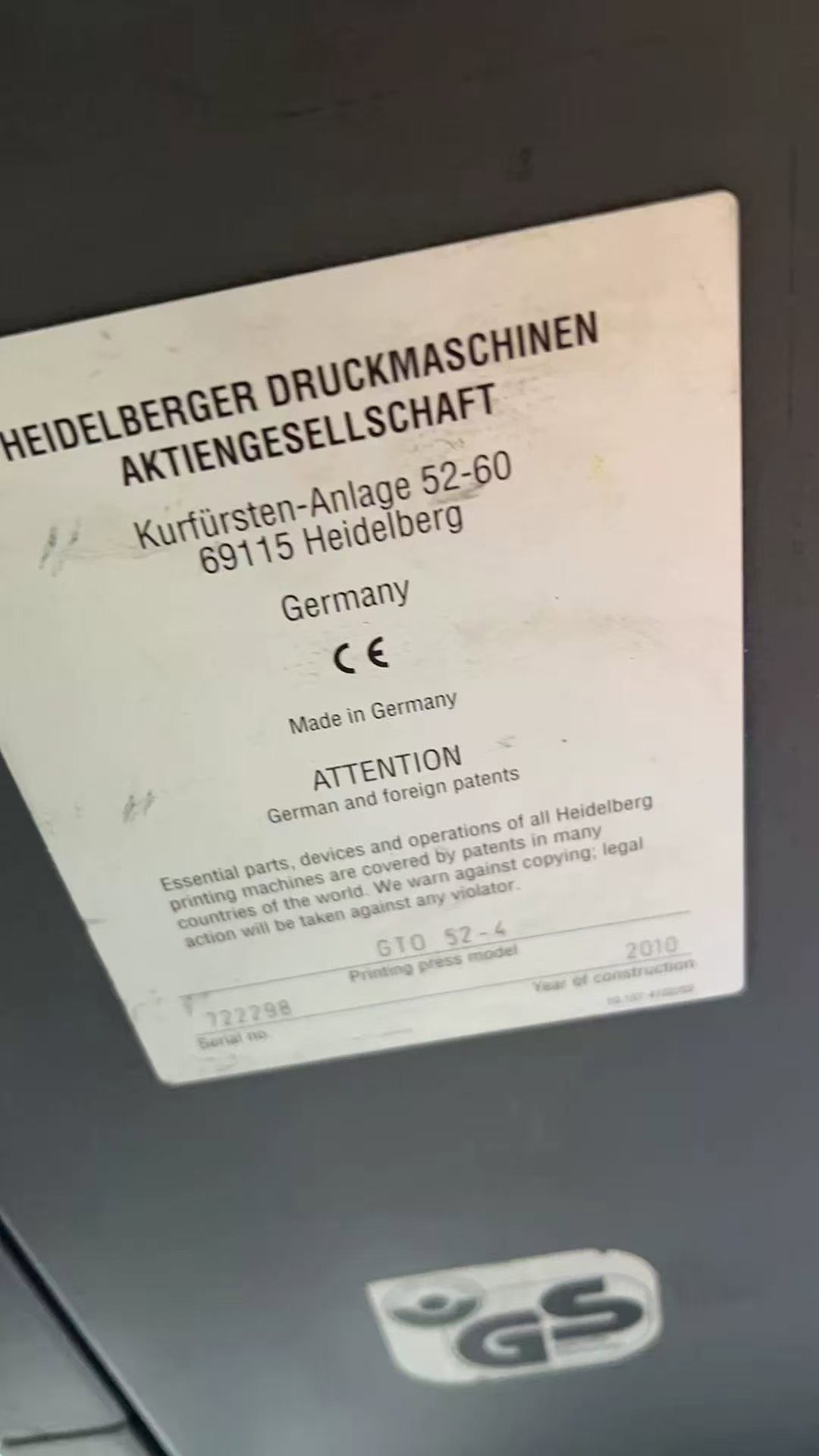

Heidelberg

GTO 52-4

2010

Sheet Fed / Offset

The Heidelberg GTO 52-4 is a high-performance sheet-fed offset press designed for precision printing in commercial and specialty applications. Belonging to the Sheet Fed / Offset category, this 4-color press delivers exceptional print quality with its perfecting capability, allowing simultaneous printing on both sides of the sheet in a single pass. Renowned for its reliability and efficiency, the GTO 52-4 is ideal for short to medium print runs, offering versatility for packaging, labels, brochures, and promotional materials. Its compact design, advanced automation, and Heidelberg's engineering excellence ensure consistent output with minimal waste, making it a preferred choice for printers seeking productivity and superior print results.

4

Guang Zhou Shi China

China

RUIAN

1300

2001

Die cutting

The RUIAN 1300 die cutting machine is a specialized industrial equipment designed for precise cutting, creasing, and shaping of paper and cardboard materials. Operating within the die cutting category, this machine is ideal for high-volume production environments requiring consistent accuracy and efficiency. Key features include robust construction, reliable performance, and compatibility with a wide range of paper weights. The RUIAN 1300 is particularly suited for applications in packaging, printing, and manufacturing industries where precision cutting is essential for product quality and workflow optimization.

Guang Zhou Shi China

China

Find the Right Equipment

Kindly add details of the equipment you seek; and you shall find. Our community of manufacturers, sellers, and professionals will procure it for you.

Click Here

The World of Print at your Fingertips

The Machine Dalal Mobile Apps

Download our Machine Dalal App Regular updates from our magazine with illustrations, innovations , commodities, history, media, art and a whole lot more from the magnificent world of Print.

Get the App

Login

Login